Preparation method of poly (1-butene) polymer, preparation method of poly (1-butene)-based membrane material master batch and poly (1-butene) membrane

A butene-based film and polymer technology, applied in the production of bulk chemicals, etc., can solve the problems affecting the mechanical properties and sealing properties of materials, the reduction of product performance, and the reduction of peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a preparation method of poly-1-butene polymer, comprising the following steps:

[0044] a) Under the protective atmosphere, under the action of composite catalyst, alkyl aluminum compound and external electron donor, the monomer raw material and hydrogen undergo a polymerization reaction to obtain a prepolymerized 1-butene alloy phase;

[0045] Described monomer raw material is 1-butene and comonomer, or is comonomer;

[0046] The comonomer is propylene and / or ethylene;

[0047] The composite catalyst is a supported titanium-based composite catalyst;

[0048] b) polymerizing the pre-polymerized 1-butene alloy phase with 1-butene and hydrogen to obtain a poly-1-butene alloy;

[0049] The molar ratio of the total amount of 1-butene to the comonomer in step a) is (0.1-20):1;

[0050] The mass ratio of the 1-butene to the total amount of the 1-butene in the step a) is 0% to 30%;

[0051] In the step a), the mass ratio of the hydrogen to the monome...

Embodiment 1

[0091] Take 0.3 kg of purified liquid phase propylene monomer and 1.7 kg of purified liquid phase 1-butene monomer.

[0092] After the 10L polymerization kettle was replaced with nitrogen, vacuum treatment was carried out until the vacuum degree reached 0Pa, and triethylaluminum, external electron donor dicyclohexyldimethoxysilane, composite catalyst (MgCl) were successively put into the reaction kettle. 2 Load TiCl 4 and internal electron donor phthalate, the amount of titanium loaded is 2.6wt%, the mass fraction of internal electron donor is 7.5%) 0.20g, put into liquid phase propylene 0.3kg, liquid phase 1-butene 0.3kg, Introduce 2.0L of hydrogen (that is, 0.18g); wherein, Al in the triethylaluminum: Ti=60:1 (molar ratio) in the composite catalyst, external electron donor: Ti in the composite catalyst=15:1 ( The molar ratio of). Through the DCS control system, the polymerization was performed at a constant temperature of 35 °C for 50 min, followed by emptying and cooling....

Embodiment 2

[0095] Take 0.45kg of purified liquid phase propylene monomer and 1.55kg of purified liquid phase 1-butene monomer.

[0096] After the 10L polymerization kettle was replaced with nitrogen, vacuum treatment was carried out until the vacuum degree reached 0Pa, and triethylaluminum, external electron donor dicyclohexyldimethoxysilane, composite catalyst (MgCl) were successively put into the reaction kettle. 2 Load TiCl 4 and internal electron donor phthalate, the amount of titanium loaded is 2.6wt%, the mass fraction of internal electron donor is 7.5%) 0.20g, put into liquid phase propylene 0.45kg, liquid phase 1-butene 0.15kg, Introduce 2.0L of hydrogen (that is, 0.18g); wherein, Al in the triethylaluminum: Ti=60:1 (molar ratio) in the composite catalyst, external electron donor: Ti in the composite catalyst=15:1 ( The molar ratio of). Through the DCS control system, the polymerization was performed at a constant temperature of 35 °C for 50 min, followed by emptying and coolin...

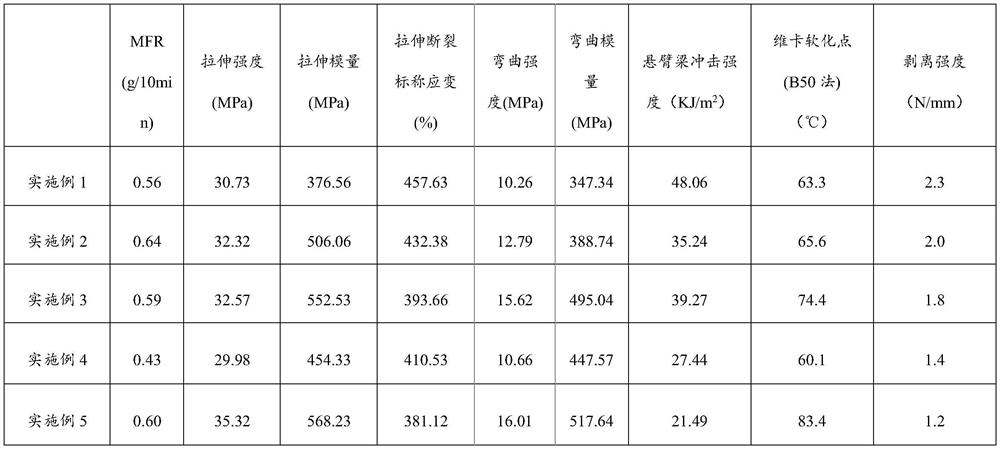

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com