Gas pipeline under-pressure leaking stoppage device and leaking stoppage method thereof

A technology for plugging leaks under pressure and gas pipelines, applied in valve devices, container filling methods, container discharge methods, etc., can solve problems such as affecting people's normal life, wasting gas resources, and natural gas leakage, avoiding environmental pollution and reducing environmental pollution. Personal safety hazards, good blocking effect, and the effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] It should be noted that the structures, proportions, sizes, etc. shown in the accompanying drawings in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with the technology, and are not used to limit the implementation of the present invention. Any modification of the structure, the change of the proportional relationship or the adjustment of the size, without affecting the effect that the present invention can produce and the purpose that can be achieved, should fall within the scope of the technical content disclosed in the present invention. within the range.

[0051] At the same time, the terms such as "up", "down", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and clarity, and are not used to limit this specification. The implementable scope of the invention, and the change or adjustment of the relati...

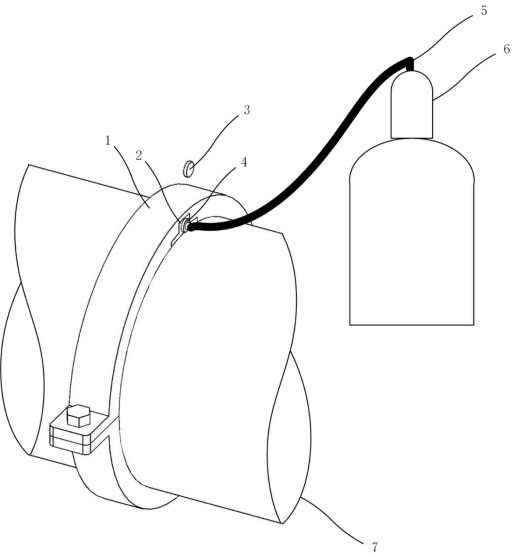

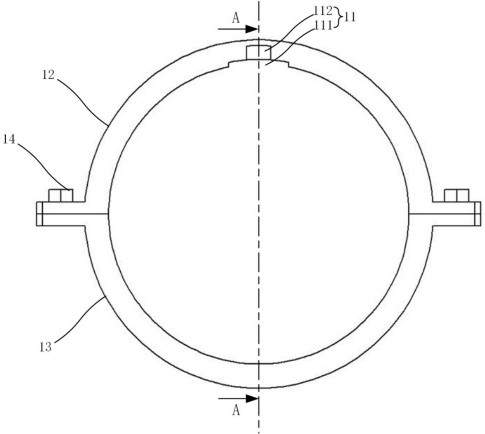

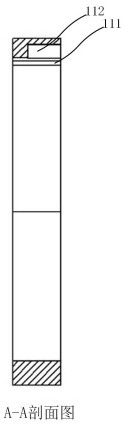

Embodiment 1

[0053] combined with Figures 1 to 5 , this embodiment provides a leakage plugging device under pressure for a gas pipeline, which includes a clamp 1 and a leakage plugging mechanism 2. The inner ring surface of the clamp 1 is axially provided with a first groove 11. The leakage plugging mechanism 2 can be tightly inserted into the first groove 11. The leakage blocking mechanism 2 includes a leakage blocking body 21 with the same curvature and the same material as the pipeline 7. The bottom of the leakage blocking body 21 is vertically provided with an air inlet 22. A cylindrical air passage 23 that communicates with the air inlet 22 is horizontally provided, and a one-way valve assembly 24 for blocking the air passage 23 is axially provided in the air passage 23, and the one-way valve assembly 24 is sealed and connected A sealing cover 3 or a connecting head 4 , one end of the connecting head 4 can be inserted into and open the one-way valve assembly 24 to communicate with th...

Embodiment 2

[0062] combined with Figures 6 to 17 , this embodiment provides a one-way valve assembly 24 suitable for Embodiment 1, and the specific technical solution is as follows:

[0063] like Image 6 and Figure 7 As shown, the one-way valve assembly 24 includes a one-way valve body 241, such as Figure 8 As shown, the one-way valve body 241 is provided with a cavity 2411 which communicates with the air passage 23. The cavity 2411 is provided with a valve seat 242 and a valve core 243, and the valve core 243 is connected to the core rod 244. The core rod 244 is symmetrically provided with two limit slide rods 2441 perpendicular to the core rod 244 , and the inner wall of the one-way valve body 241 is axially provided with a limit rod corresponding to the limit slide rod 2441 . The position slide groove 2412 and the spring 245 are arranged between the end of the one-way valve body 241 away from the valve seat 242 and the limit slide rod 2441, and the valve core 243 and the core ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com