Single-hole ultrasonic detection device and method for continuous integrity and rock penetration depth of concrete anti-seepage wall body

An ultrasonic detection and integrity technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem that the quality of the wall cannot be reflected, the detection workload increases, and it is economical and issues such as time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

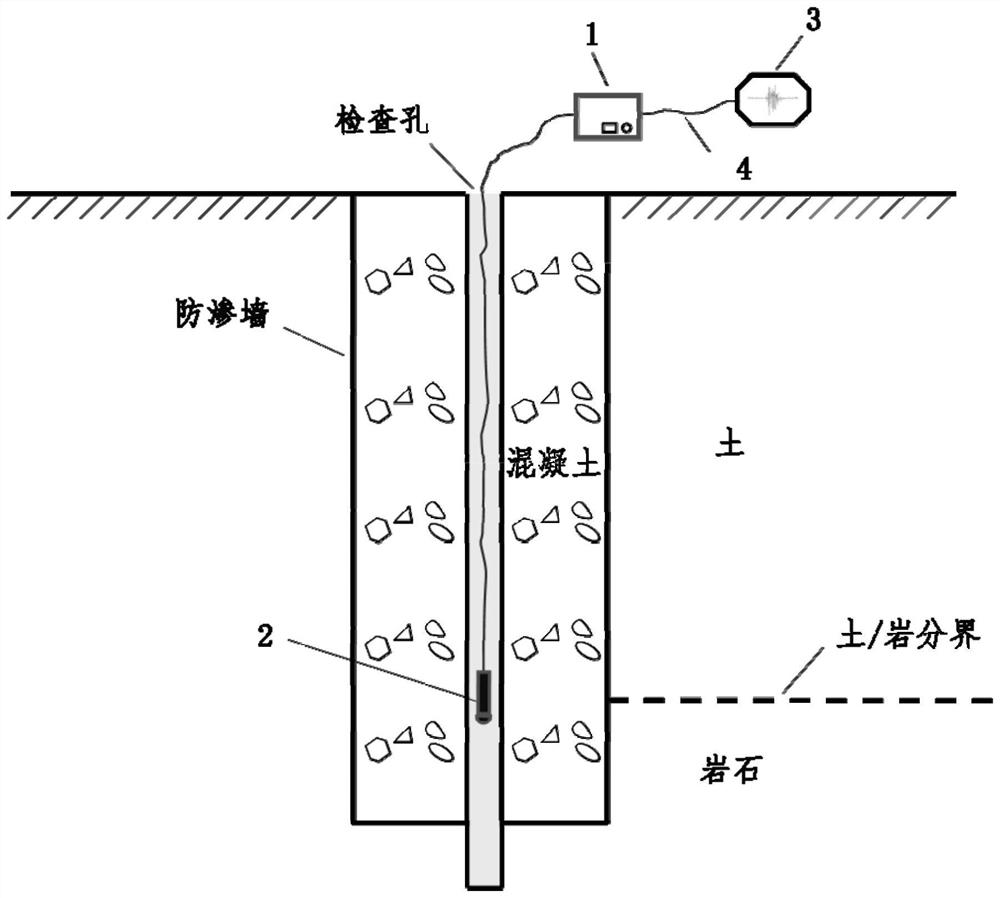

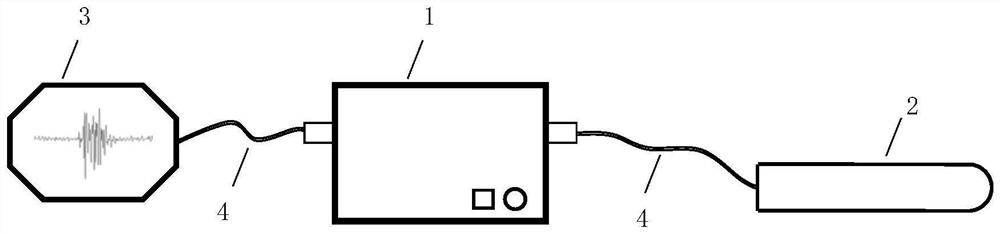

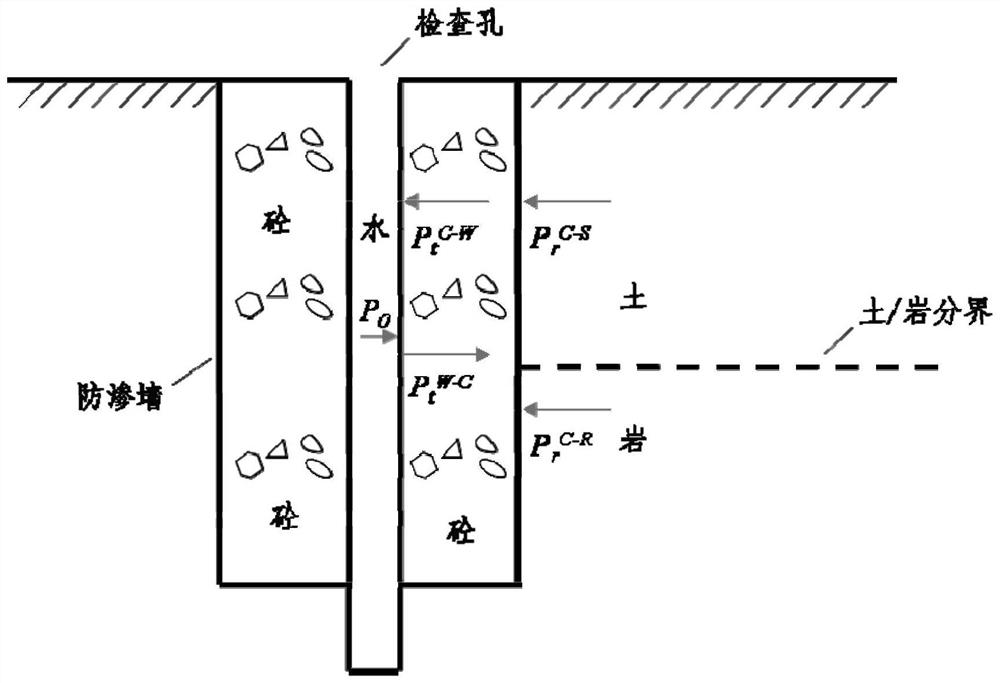

[0043] like Figure 1-Figure 4 As shown in the figure, the present invention provides a single-hole ultrasonic detection device for the continuous integrity of the concrete anti-seepage wall and the depth of penetration into the rock.

[0044]The detection device includes an equipment host 1, an ultrasonic transducer 2, and an ultrasonic signal feedback device 3. The equipment host 1 is respectively connected with the ultrasonic transducer 2 and the ultrasonic signal feedback device 3 through wires. The equipment host 1 Set as an ultrasonic transmitting and receiving device, the ultrasonic transmitting and receiving device includes an ultrasonic transmitting module and an ultrasonic signal acquisition module, and the ultrasonic transmitting module is used to generate ultrasonic waves and transmit them through the ultrasonic transducer 2. The ultrasonic transducer 2 It is used to collect and recover the reflected ultrasonic waves, and convert the recovered ultrasonic informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com