Coated colored solid particles comprising at least one direct dye and/or one oxidation dye precursor

A technology of solid particles and oxidative dyes, applied in the field of dyeing keratin fibers, can solve problems such as different final effects, and achieve the effects of good dissolution and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

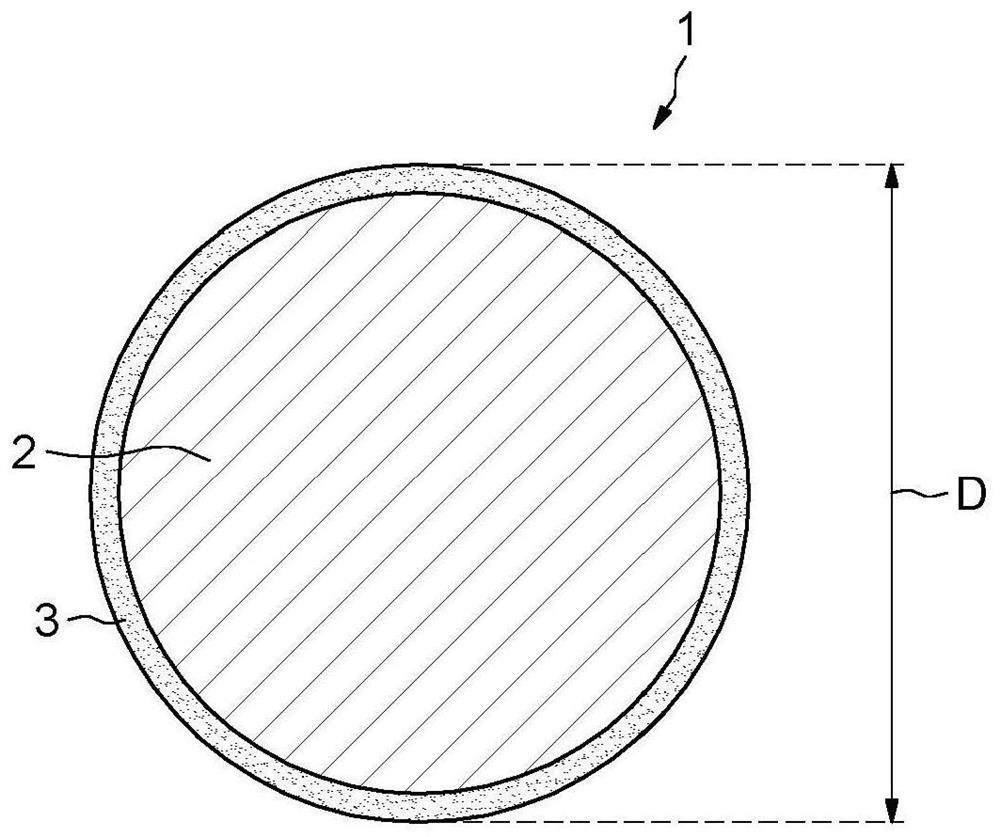

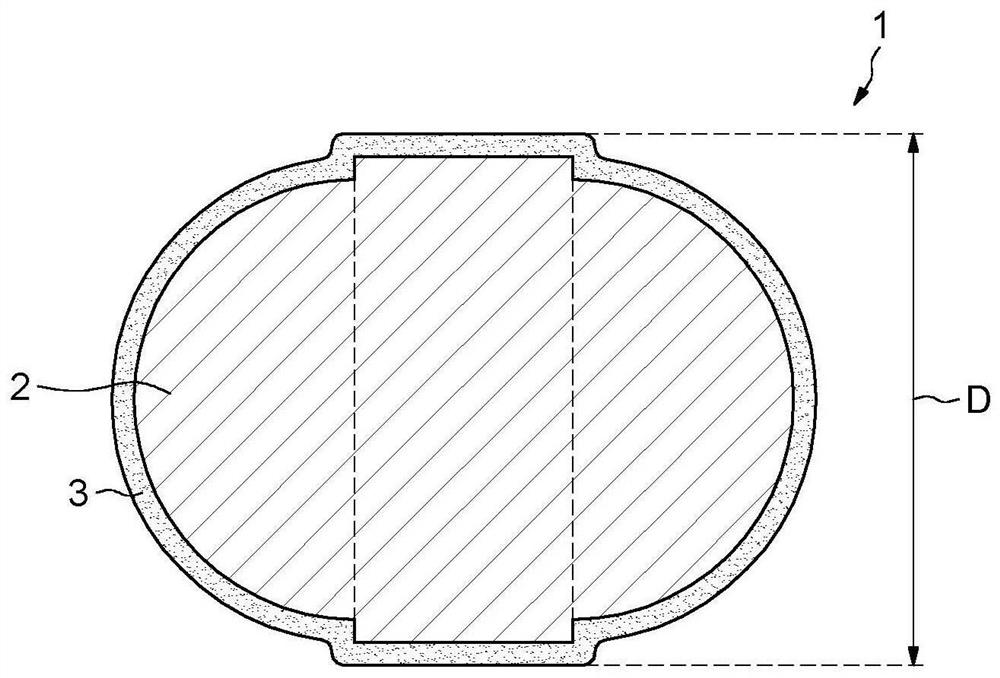

Image

Examples

preparation example Construction

[0178] According to another specific preparation method, the solid particles according to the present invention can be prepared via wet granulation according to the following steps:

[0179] - pre-mixed binders (eg lactose, microcrystalline cellulose, polyvinyl alcohol (PVA)) and direct dyes and / or oxidation dye precursors; and then

[0180] - spraying onto the premix a disintegrant (eg cross-linked polyvinylpyrrolidone) dissolved in one or more solvents as described in the paragraph above for the coating to produce the desired pellets those described in the coating composition, especially water; and then

[0181] - drying the pellets; and then

[0182] - grinding the other components of the solid particles; and then

[0183] - screening powders and granules obtained by grinding; and then

[0184] - mix the powder obtained by screening; and then

[0185] - compressing the obtained mixture directly into solid particles; and optionally

[0186] - Coating the obtained solid ...

example

[0382] The following solid particles and compositions according to the invention were prepared using the following ingredients, the content of which is indicated in the table below in terms of mass percent of active substance relative to the total weight of the solid particles or composition.

[0383] example of particles

[0384] Solid particles without an overcoat

[0385] [Table 1]

[0386] Element quantity microcrystalline cellulose 56 lactose 15 PVP 4.75 Magnesium stearate 2 silica 1 Toluene-2,5-diamine sulfate 20 Sulfite 1 water 0.25

[0387] Examples of upper coating layers

[0388] [Table 2]

[0389] Element quantity Hydroxypropyl methylcellulose (HPMC) 45 to 55 Hydroxypropyl Cellulose (HPC) 5 to 20 Capric / Caprylic Triglycerides 1 to 10 talc Appropriate amount to 100 pigment 0 to 40

[0390] Example of Solid Particles with Overcoat

[0391] [T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com