System and method for recovering VOCs (volatile organic compounds) through normal-temperature condensation

A technology of condensation recovery and recovery method, which is applied in the normal temperature condensation recovery VOCs system and recovery field, can solve the problems of low energy consumption, etc., and achieve the effect of simple use of equipment, reasonable process flow and easy manufacture

Pending Publication Date: 2022-05-31

班戈设备系统(苏州)有限公司

View PDF12 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, the above-mentioned prior art cannot solve the technical problem of how to realize low energy consumption and close to normal temperature recovery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] The above-mentioned embodiment is only the preferred technical solution of the present invention, and should not be regarded as a limitation of the present invention. this hair

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

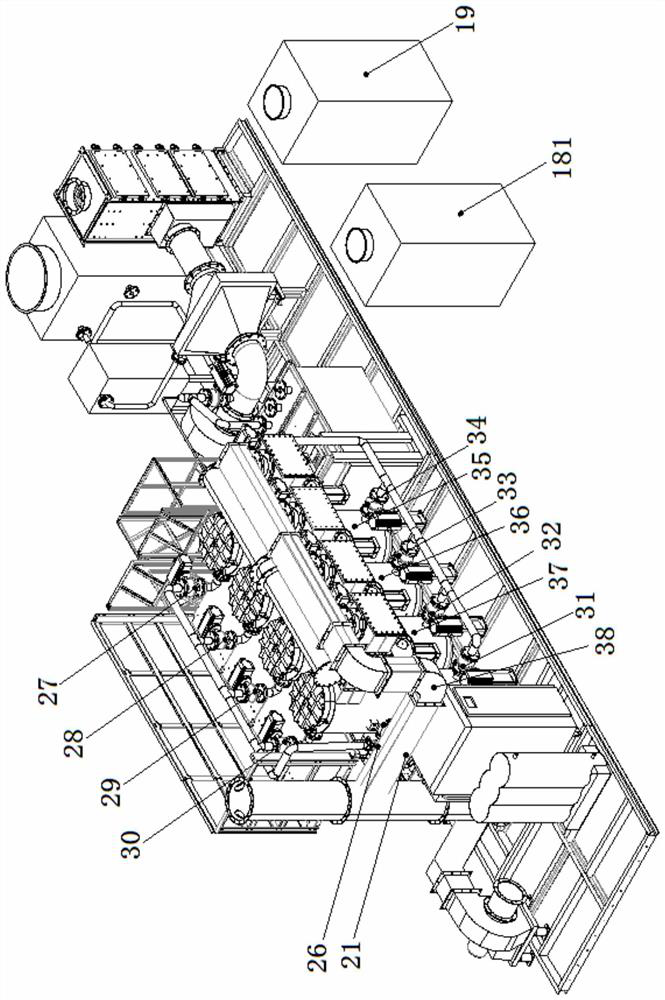

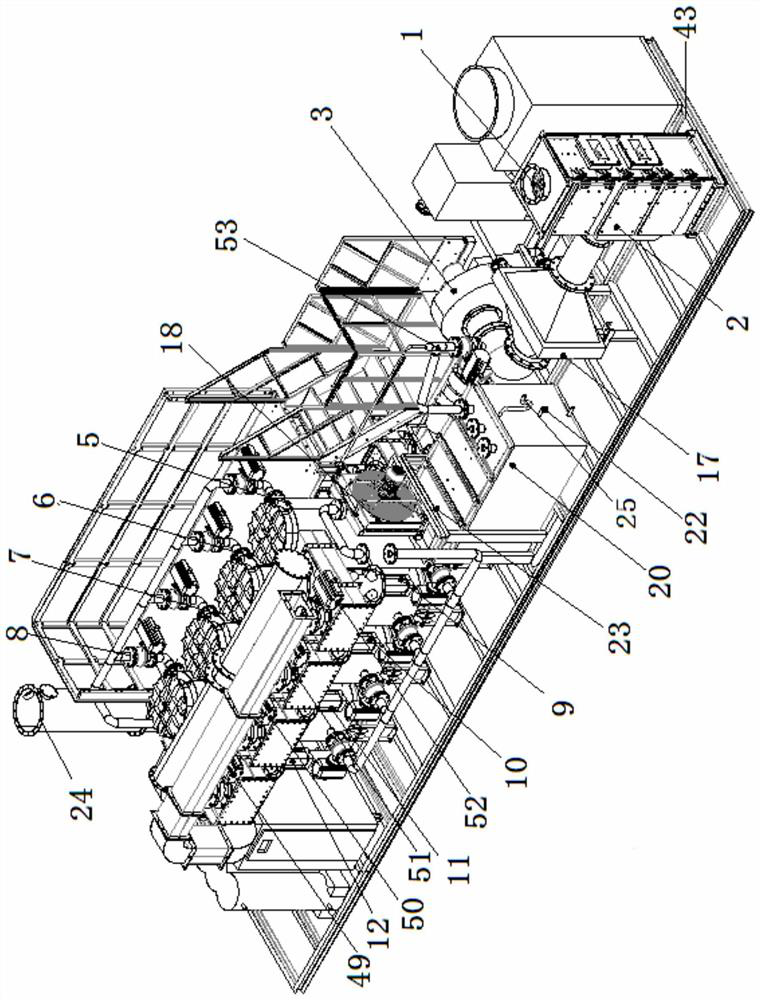

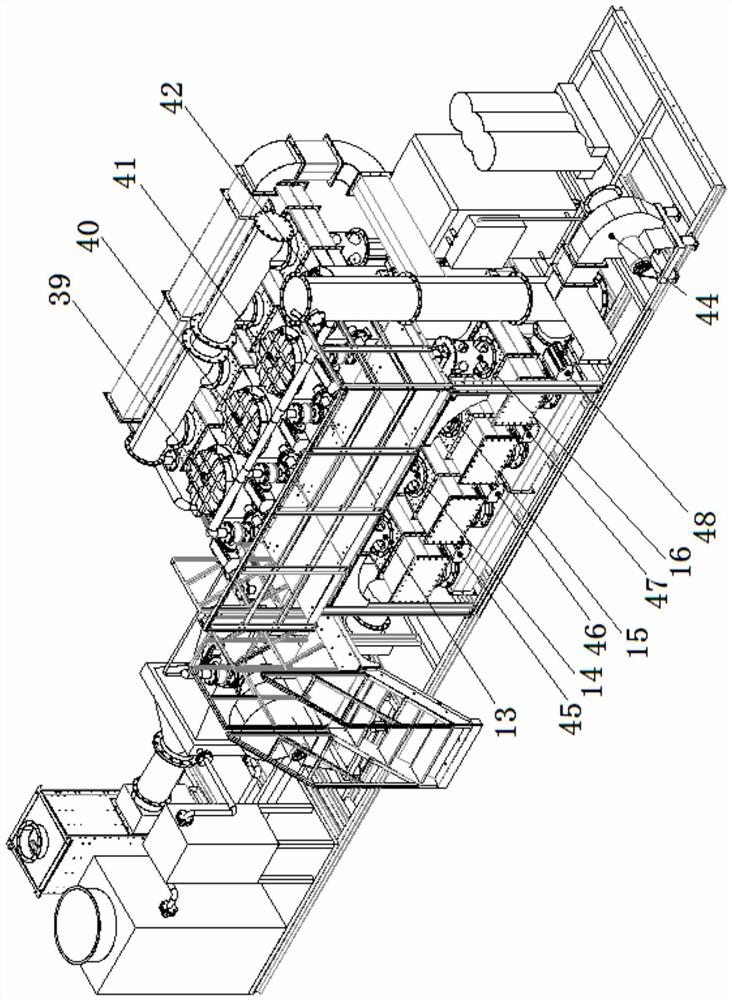

The invention belongs to the technical field of environmental protection, and particularly relates to a system for recovering VOCs through normal-temperature condensation. The device is characterized by comprising the following components: a waste gas inlet, a filter device, a traction fan, first to fourth activated carbon adsorption tanks, first to eighth lifting valves, a precooler, a condenser, a purification tank, a storage tank, an oil-water separator, a steam inlet, a liquid discharge port, a gas-liquid mixture discharge port, an exhaust funnel, a water discharge port, a steam pressure reducing valve and first to eighth steam valves, the system comprises a first to fourth activated carbon adsorbent, a first to fourth access door, a rack, a cooling fresh air fan, a first to fourth cooling fresh air inlet valve, a first to fourth cooling fresh air outlet valve, a cooling return pipe and the like. The invention further discloses a recovery method. The device has the main beneficial effects of being easier to manufacture, simple to use, more reasonable in treatment flow, more environmentally friendly and more energy-saving.

Description

A room temperature condensation recovery VOCs system and recovery method technical field The invention belongs to the technical field of environmental protection, especially relate to a kind of normal temperature condensation recovery VOCs system and recovery method. Background technique [0002] There are two main types of VOCs treatment technologies: one is recycling technology, and the other is destruction technology. recycling technology is Change the physical conditions such as temperature and pressure of a certain process to enrich and separate VOCs, and give priority to recycling, which is unfavorable for Use the value to take further harmless treatment. Destruction technology is mainly through chemical or biochemical reactions, using heat, light, catalysts and microorganisms to convert organic matter into non-toxic or low-toxic small molecule compounds such as carbon dioxide and water, VOCs can be treated reason. The VOCs treatment technologies in the prior ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/04B01D46/62B01D53/00

CPCB01D53/0407B01D53/002Y02A50/20

Inventor 李晓强

Owner 班戈设备系统(苏州)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com