Molten iron scheduling method and system based on steelmaking molten iron quality requirement

A scheduling system and quality requirements technology, applied in manufacturing computing systems, furnaces, manufacturing tools, etc., can solve problems such as reducing steel welding performance, steel hot brittleness, and molten iron scheduling failure, reducing processing costs, improving hit rates, increasing The effect of match rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

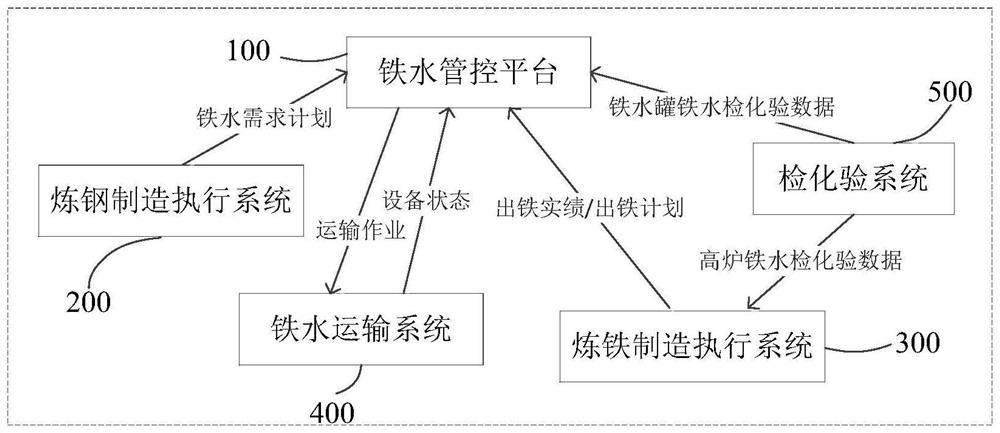

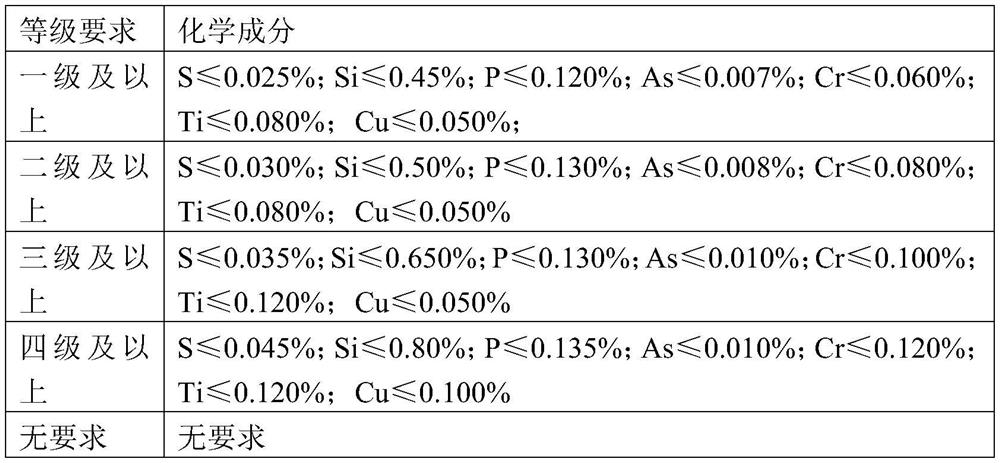

[0054] In steelmaking enterprises, due to the different types of steel produced, the required quality requirements of molten iron are also different. Because the railway transportation center cannot know the quality of blast furnace molten iron in time, it can only dispatch molten iron according to the demand of molten iron in steelmaking. In the process of smelting ordinary steel grades (ordinary steel grades have no hot metal quality requirements), this scenario does not affect the subsequent work of the steelmaking plant, but if the steelmaking plant needs to smelt high-grade steel, it has special quality requirements for molten iron , then if the iron transportation center still cannot understand the quality requirements of molten iron in time according to the demand of molten iron, there will be molten iron dispatched that does not meet the smelting requirements of steelmaking, which will lead to an increase in the smelting cost of molten iron by the steelmaking plant, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com