Aluminum material chemical polishing solution and polishing method thereof

A technology for chemical polishing and polishing liquid, applied in the field of polishing liquid, can solve the problem of pollution that cannot be recycled and used, and achieve the effects of remarkable polishing effect, low emission, and easy recycling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a chemical polishing liquid for aluminum materials, which is prepared by mass percentage of the following raw materials: 20% of quaternary phosphonium hydrogen sulfate ionic liquid, 1% of citric acid, 3% of polyethylene glycol and the balance of water.

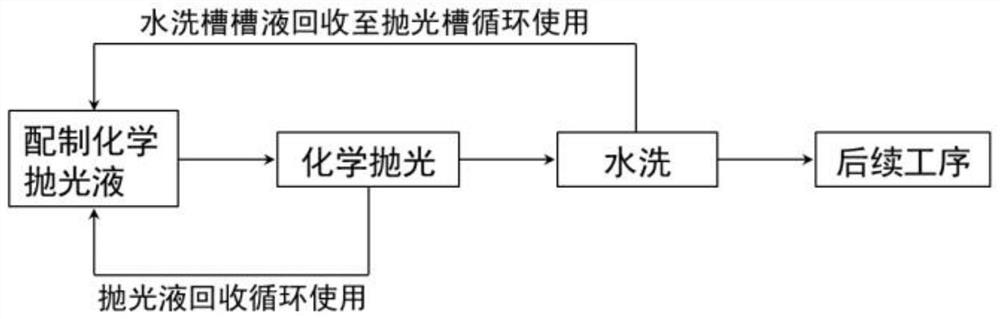

[0028] see figure 1 , this embodiment also provides a polishing method for aluminum chemical polishing liquid, comprising the following steps:

[0029] Step 1: First, prepare the chemical polishing liquid for aluminum materials by ionic liquid, additives and water according to the actual required ratio, and introduce it into the polishing tank and heat it to 60 °C for use;

[0030] Step 2: First clean the surface of the aluminum to be polished, then put the cleaned aluminum directly into the aluminum chemical polishing solution in the polishing tank to soak for 2 minutes, then take out the aluminum and put it into the washing tank to wash with water Clean and finish chemical polishing of alumi...

Embodiment 2

[0035] This embodiment provides a chemical polishing liquid for aluminum materials, which is prepared from the following raw materials by mass percentage: 5% tributyloctylcarboxylate quaternary phosphonium dihydrogen phosphate ionic liquid, 1% phosphotungstic acid, 2% % polyethylene glycol, 0.5% coco acid diethanolamide, balance water.

[0036] see figure 1 , this embodiment also provides a polishing method for aluminum chemical polishing liquid, comprising the following steps:

[0037]Step 1: First, prepare the chemical polishing liquid for aluminum materials by ionic liquid, additives and water according to the actual required ratio, and introduce it into the polishing tank and heat it to 35 °C for use;

[0038] Step 2: First clean the surface of the aluminum to be polished, then put the cleaned aluminum directly into the aluminum chemical polishing solution in the polishing tank to soak for 6 minutes, then take out the aluminum and put it into the washing tank to wash with...

Embodiment 3

[0043] This embodiment provides a chemical polishing liquid for aluminum materials, which is prepared by the following raw materials by mass percentage: 15% trimethylbutylcarboxylate quaternary phosphonium hydrogen oxalate ionic liquid, 2% citric acid, 1% Polyethylene glycol, 0.5% coco acid diethanolamide, balance water.

[0044] see figure 1 , this embodiment also provides a polishing method for aluminum chemical polishing liquid, comprising the following steps:

[0045] Step 1: First prepare the chemical polishing liquid for aluminum material by ionic liquid, additives and water according to the actual required ratio, and introduce it into the polishing tank and heat it to 80 °C for use;

[0046] Step 2: First clean the surface of the aluminum to be polished, and then put the cleaned aluminum directly into the aluminum chemical polishing solution in the polishing tank to soak for 0.5 minutes, then take out the aluminum and put it into the washing tank to wash with water Cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com