Recyclable polylactic acid functional quilt easy to recycle and preparation method thereof

A polylactic acid and functional technology, which is applied in the field of quilt preparation, can solve the problems of inefficiency such as inability to recycle, recycle and reuse, and achieve the effects of reducing energy consumption, improving efficiency, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

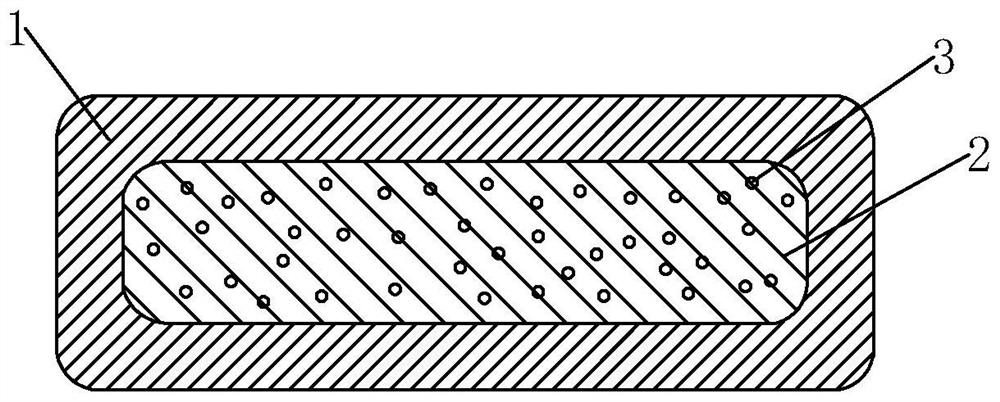

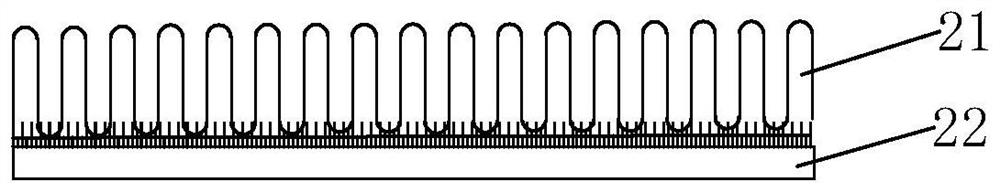

[0027] combine Figure 1 to Figure 3 , the present invention is described in detail. The present invention relates to a recyclable and easily recyclable polylactic acid functional quilt and a preparation method thereof. The functional quilt includes a quilt cover 1 and a quilt core 2, and the grammage range of the polylactic acid woven fabric is 90- 160 grams per square meter. The fineness of the polylactic acid spun yarn is 28-50 lbs; the polylactic acid staple fiber used in the polylactic acid spun yarn has a fineness of 0.8-1.5D and a length of 38-51mm. Polylactic acid filaments are selected as warp yarns, so that sizing can not be carried out during weaving, so that desizing is not required, and the weaving efficiency is improved. When using polylactic acid woven fabrics for sewing quilt covers, the sewing used is also made of polylactic acid. If the zipper is also used in the quilt cover, the material used for the zipper is polylactic acid resin, so that the entire qui...

Embodiment 2

[0039] combine Figure 4 , to describe this embodiment in detail. A recyclable and easily recyclable polylactic acid fiber functional quilt and its preparation method involved in this embodiment differ from Embodiment 1 in that:

[0040] The short polylactic acid fibers constituting the polylactic acid fiber batt contain an airgel component 4 inside and are hollow and have a hollow portion 5 . In the polylactic acid short fibers that make up the polylactic acid fiber flakes, the content of the airgel powder is 0.4-1.5%, specifically 0.52%, by weight. Specifically, the airgel powder in this embodiment is silica airgel powder. It can also be other airgel powders. The airgel powder has a diameter of 0.1-20 microns and a porosity greater than 90%. The thermal conductivity of the silicon dioxide airgel powder is lower than 0.02w / m·K, and has good thermal insulation performance.

[0041] The test result of the thermal conductivity of the polylactic acid multifunctional substrate ...

Embodiment 3

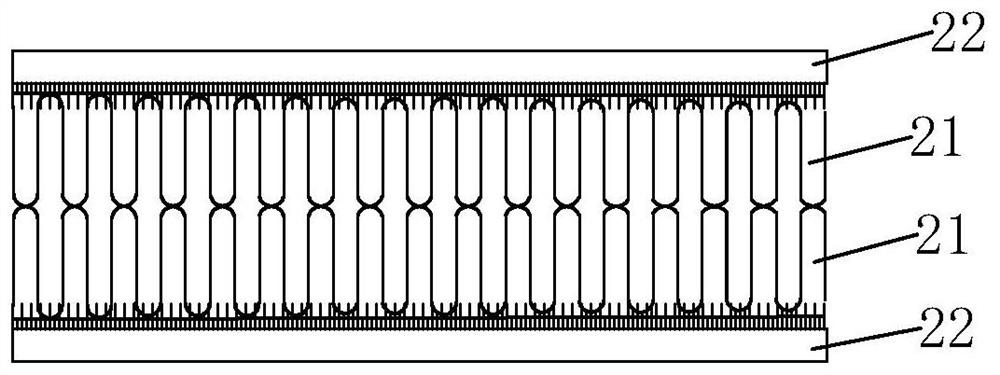

[0043] combine Figure 5 , to describe this embodiment in detail. The recyclable and easily recyclable polylactic acid fiber functional quilt and its preparation method involved in this embodiment differ from Embodiment 1 in that:

[0044] In this embodiment, the quilt core 2 is made by quilting three layers of polylactic acid fiber upright batting. The reason why three layers are adopted is to improve the thickness of the quilt core 2 and improve the weight and warmth retention of the quilt. The test result of the thermal conductivity of the polylactic acid multifunctional substrate prepared in this embodiment is 0.025W / (m·k), which has a good thermal insulation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com