Elliptical finned tube type heat exchanger and elliptical finned tube type intelligent phase-change heat exchange device

A finned tube type, phase-change heat technology, applied in the direction of heat exchanger sealing device, indirect heat exchanger, heat exchanger type, etc., can solve the problem of reducing the amount of heat exchanged by the fluid in the tube and affecting the heat transfer efficiency of the finned tube , heat transfer coefficient reduction between fluids, etc., to achieve the effect of improving the convenience of flushing, increasing the heat transfer coefficient, and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

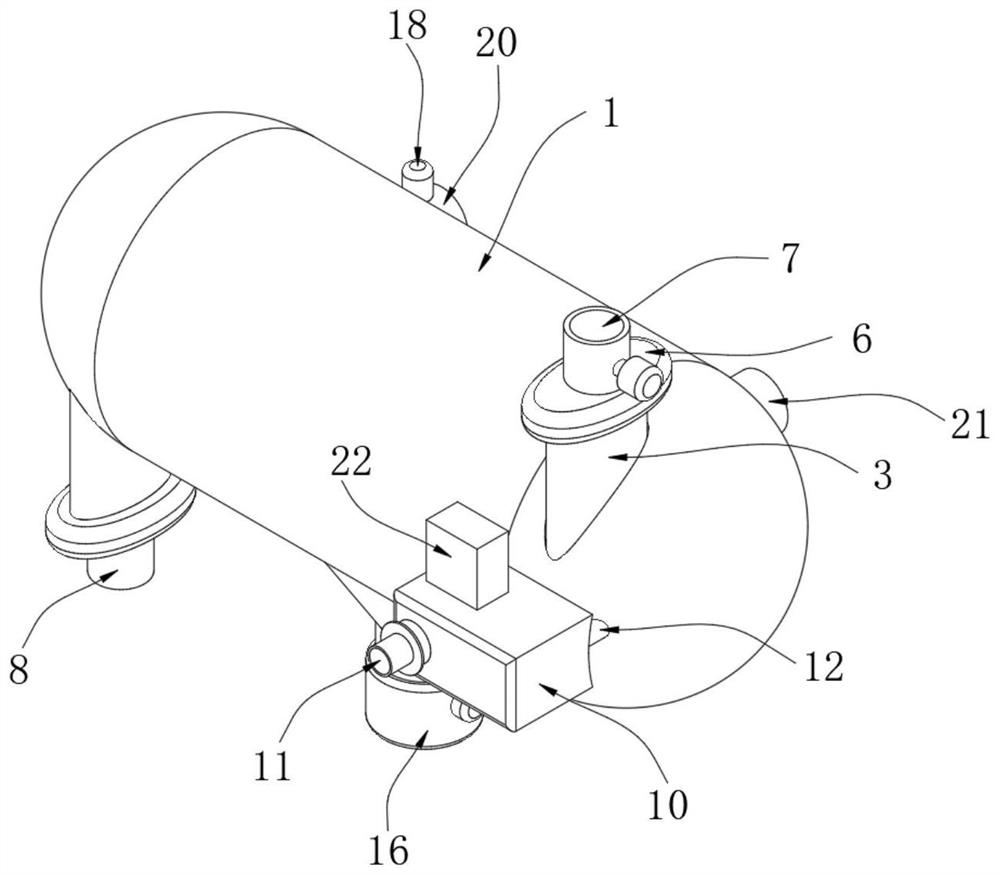

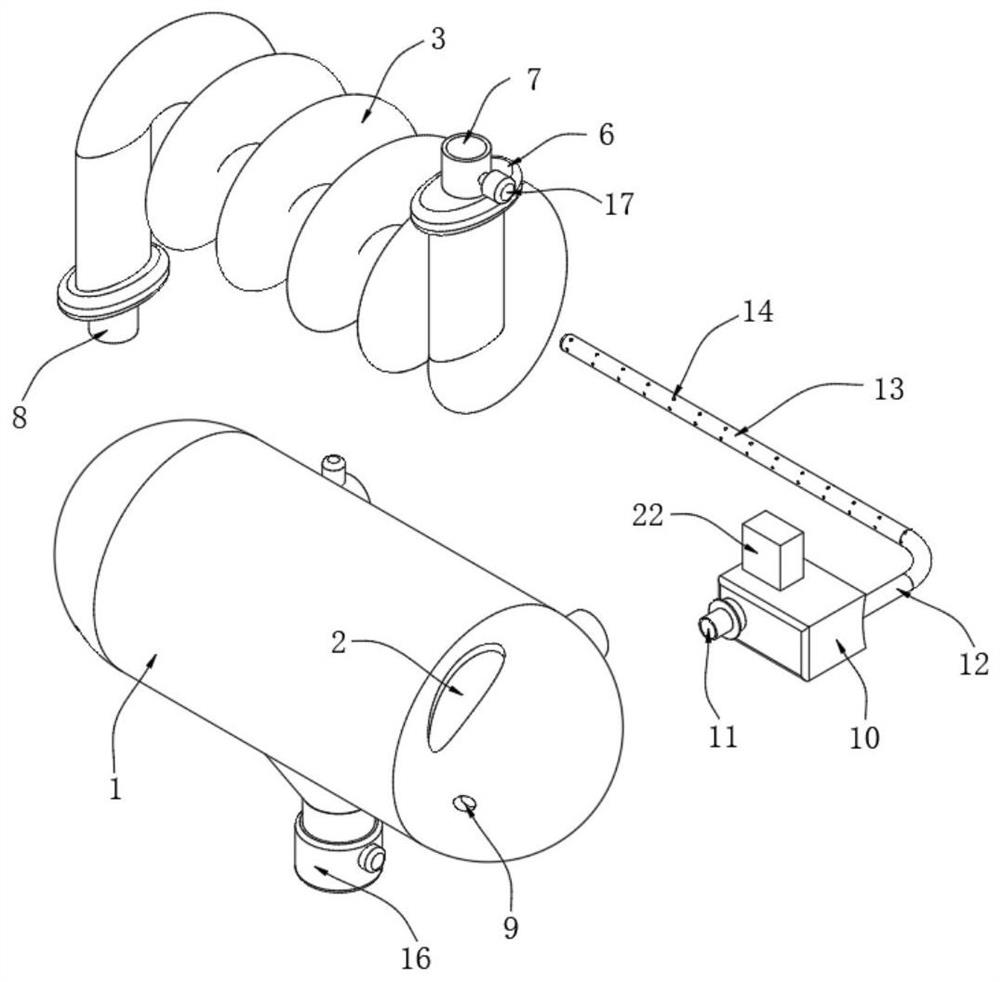

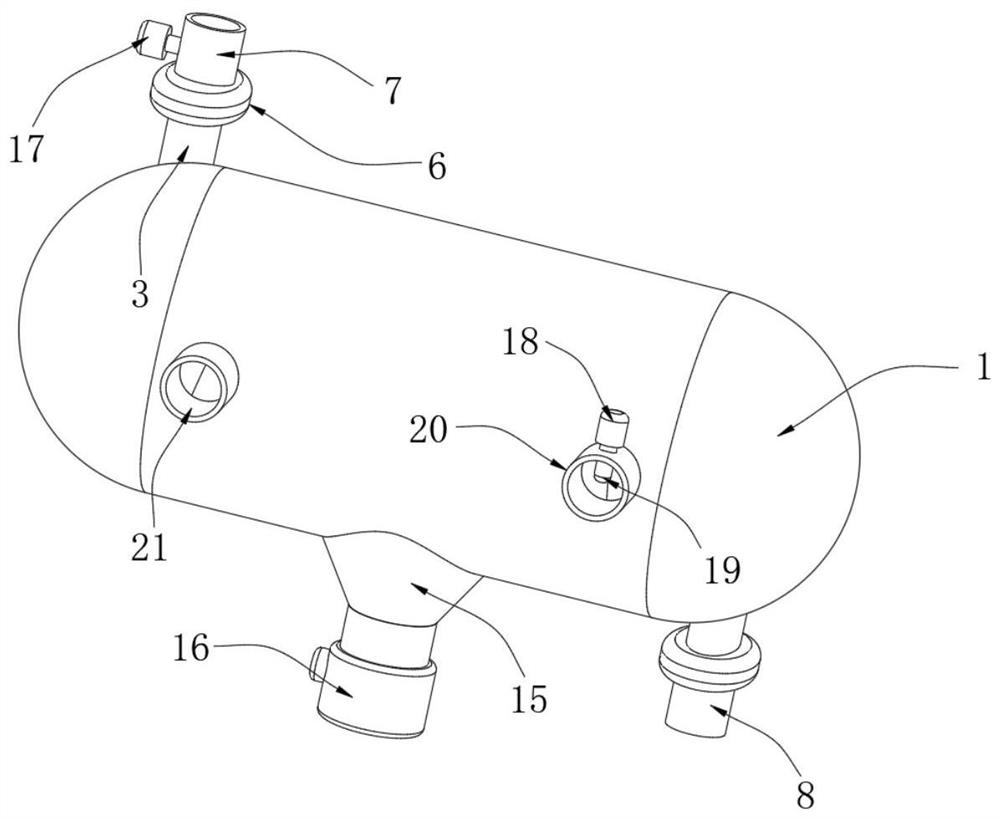

[0028] see figure 1 - Image 6 , the present invention provides the following technical solutions: an elliptical finned tube heat exchanger and an elliptical finned tube type intelligent phase-change heat device include a heat exchange barrel 1, a heat exchange mechanism is arranged in the heat exchange barrel 1, and the heat exchange mechanism From the elliptical finned tube and the inlet joint structure and outlet joint structure connected to the beginning and end of the elliptical finned tube, the heat exchange barrel 1 is connected with the flue gas inlet structure and the flue gas outlet structure, and the heat exchange barrel 1 is provided with a dust washing mechanism. The flue gas inlet structure and the outlet joint structure are equipped with a detection mechanism. The elliptical finned tube is composed of an elliptical base tube 3. The elliptical base tube 3 is spirally wound in the heat exchange barrel 1. There are two through grooves 2 on the heat exchange barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com