Double-chamber lime kiln suspension cylinder temperature monitoring method and system and storage medium

A double-chamber lime kiln and monitoring system technology is applied in thermometers, lime production, and thermometers using electric/magnetic elements that are directly sensitive to heat. It can solve the problems of being unable to effectively capture local over-temperature and extend the operating life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

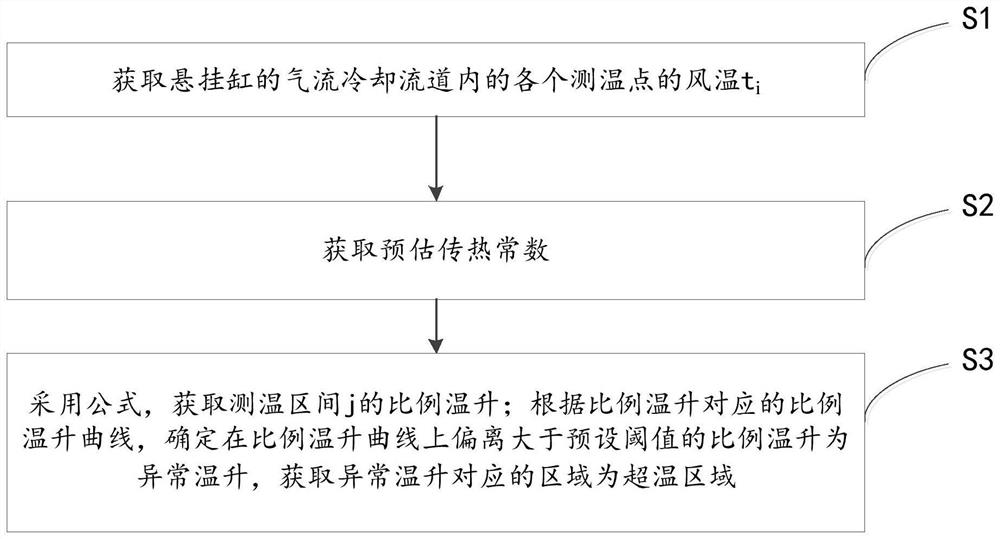

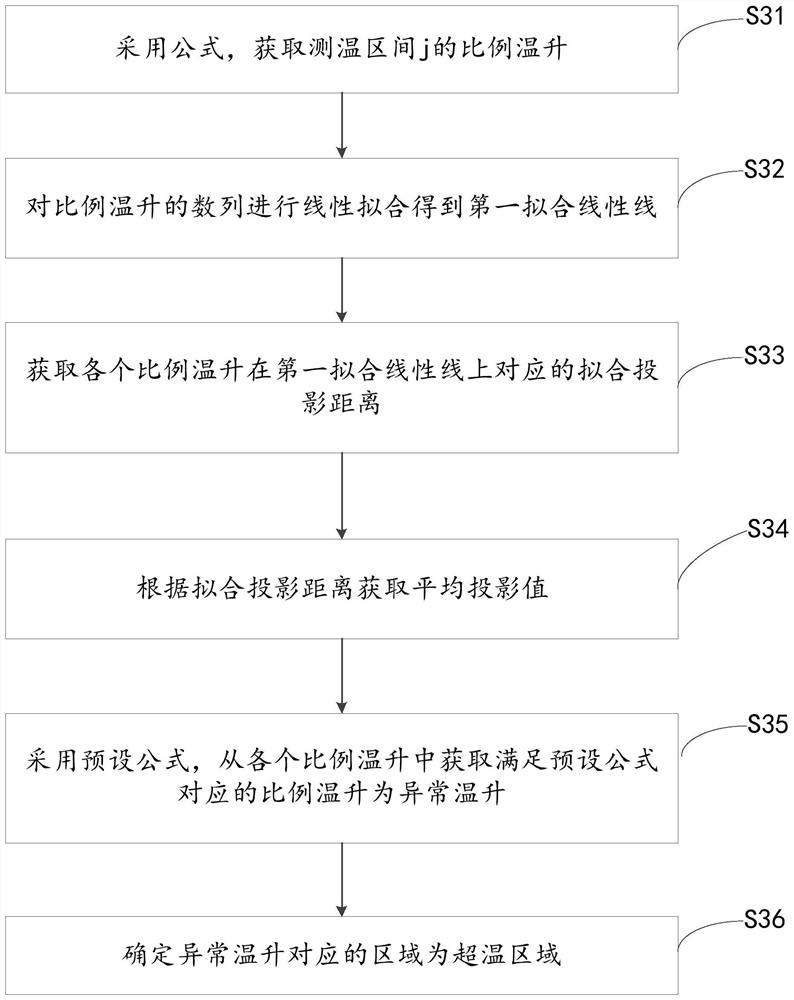

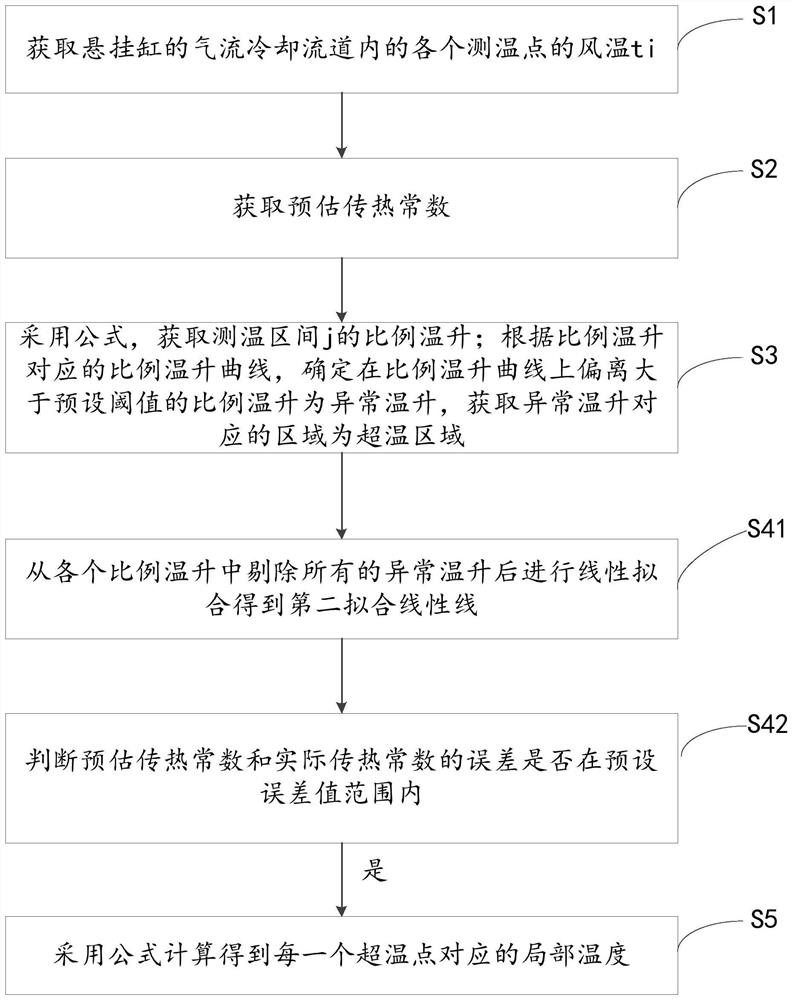

[0035] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0036] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only

[0037] In addition, in the present invention, the description related to "first", "second", etc. is only for the purpose of description, and should not be construed as referring to

[0045] y

[0047]

[0049] Understandably, y

[0052] y

[0057]|c

[0060]|c

[0061] Show that the error is in the acceptable range, then jump to step S5. where k

[0063]

[0064] The average projection value d' is obtained by calculation.

[0074] Optionally, it also includes an intake duct 80 that is arranged outside the suspension cylinder 100 and communicated with the intake inlet, and is arranged in the suspension

[0076] Optionally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com