Rapid detection method for coal gangue aggregate weathering in service state and application thereof

A service status and detection method technology, applied in the direction of measuring devices, analysis materials, climate sustainability, etc., can solve the problems of adverse impacts on the ecological environment, occupation of cultivated land, etc., to avoid performance degradation, relieve stockpiling pressure, and simplify the work process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, the cement slurry is used to wrap the coal gangue aggregate to simulate the service state of the coal gangue aggregate in the concrete or semi-rigid base material, and it is cured for 14 days, and the cement is fully hydrated through curing, so as to simulate the condition of being in the concrete and semi-rigid base material. The service status of coal gangue aggregates in the material. Among them: the coal gangue aggregate used is coarse coal gangue aggregate, the particle size is 9.5-13.2mm, and the mass of each group is 3000g; the cement used in the cement slurry is P.O42.5 cement, the water-cement ratio is 0.45, and artificial mixing is adopted. method, the cement slurry is evenly wrapped on the surface of each coal gangue aggregate to form a thin layer no more than 0.5mm.

[0028] The weathering conditions of ordinary coal gangue aggregates and coal gangue aggregates wrapped with cement slurry were evaluated according to the following steps:

[0...

Embodiment 2

[0040] This example is the same as Example 1, except that three groups of ordinary coal gangue aggregates and coal gangue aggregates wrapped with cement slurry are taken out, and subjected to accelerated weathering treatment at a temperature of 50°C for 7 days, 14 days, 21 days and 28 days, and numbered as coal gangue E, coal gangue F, coal gangue G and coal gangue H.

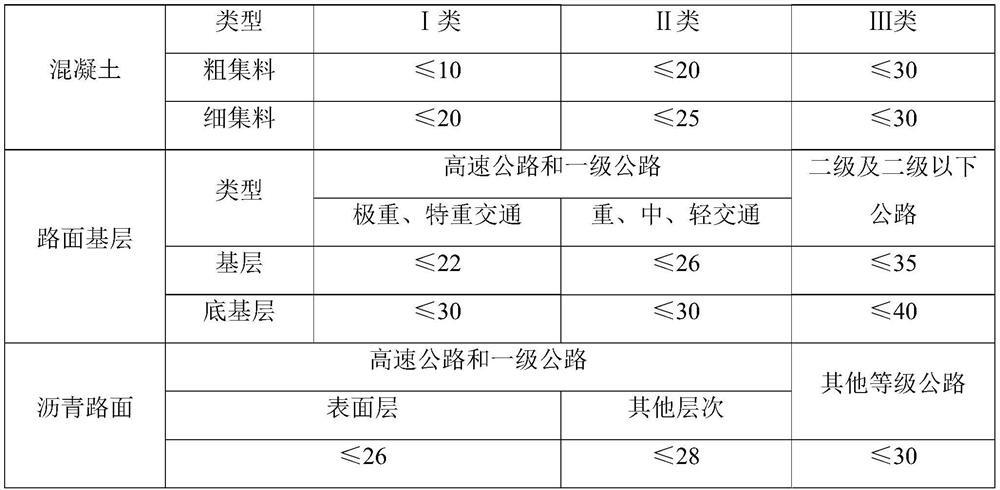

[0041] The crushing values of coal gangue aggregates in different states obtained in this example are shown in Table 3 below.

[0042] Table 3 Coal gangue crushing value before and after weathering treatment

[0043]

[0044] The change of crushing value of ordinary coal gangue aggregate and coal gangue aggregate wrapped with cement slurry in each group after weathering is as follows: coal gangue E increases by 3.8% and 6.4% respectively; coal gangue F increases by 6.7% and 8.9% respectively %; coal gangue F increased by 9.3% and 11.3% respectively; coal gangue H increased by 9.4% and 11.5% respectively. ...

Embodiment 3

[0049] In this example, the coal gangue aggregate is wrapped with an asphalt binder to simulate the service state of the coal gangue aggregate in the asphalt mixture, and the asphalt binder used is petroleum asphalt.

[0050] The weathering of coal gangue aggregates wrapped with ordinary coal gangue aggregates and asphalt binders was evaluated according to the following steps:

[0051] Step 1: Detect the crushing value of ordinary coal gangue aggregate without weathering treatment and the crushing value of coal gangue aggregate wrapped with asphalt binder.

[0052] Step 2: The ordinary coal gangue aggregate and the coal gangue aggregate wrapped with the asphalt binder are subjected to accelerated weathering treatment at 70° C. for a total of 20 days.

[0053] Step 3: Detect the crushing value of the weathered ordinary coal gangue aggregate and the crushing value of the coal gangue aggregate wrapped with the asphalt binder.

[0054] The crushing value of the unweathered ordina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com