Jet printing ink drop point error prediction method

An error prediction and ink droplet technology, which is applied in the field of inkjet printing, can solve the problem of low efficiency of drop point error prediction, achieve the effect of strengthening overall and local optimization capabilities, maintaining diversity, and improving diversity and ergodicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

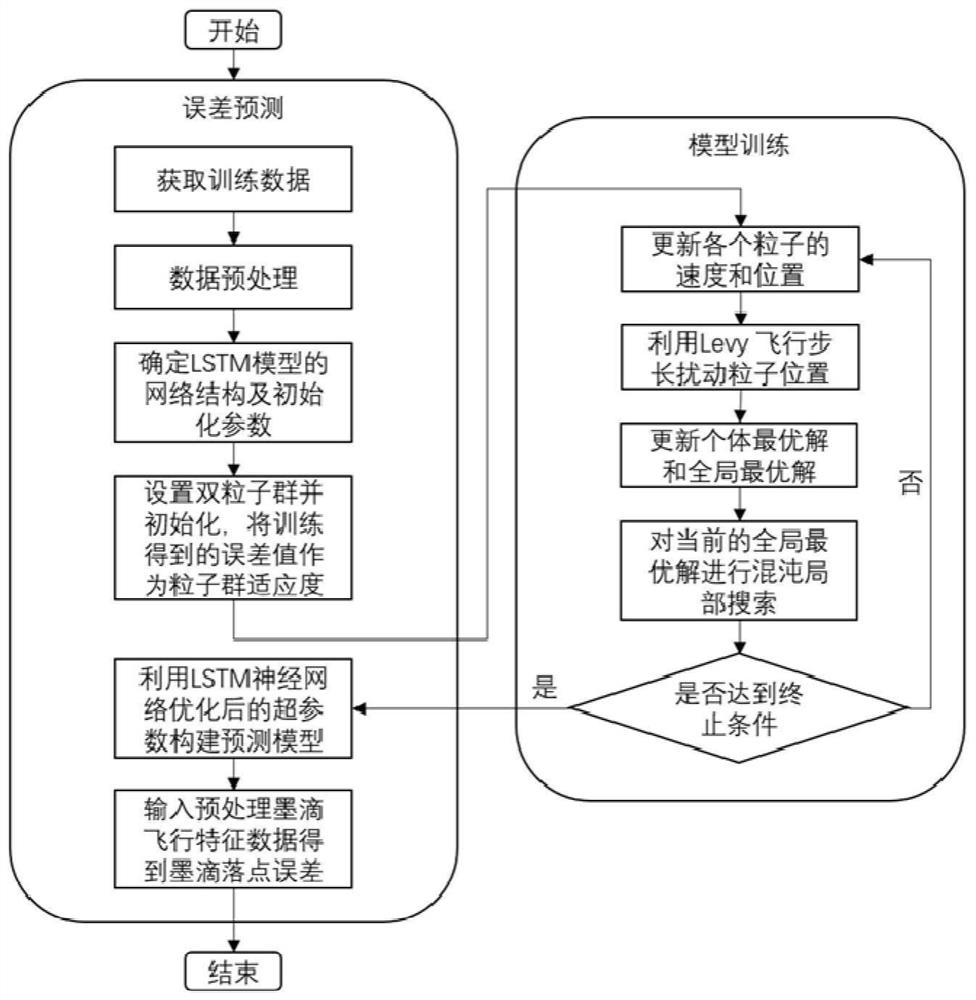

[0059] A LSTM neural network model construction method for jet printing ink drop point error prediction, such as figure 1 As shown, it includes: determining the network structure of the LSTM neural network model, using the improved dual particle swarm optimization algorithm to optimize the hyperparameters of the network structure, and using the training sample set to train the hyperparameter optimized network structure, and obtaining the ink used for jet printing. The LSTM neural network model of drop point error prediction; the optimization mode of described hyperparameter is:

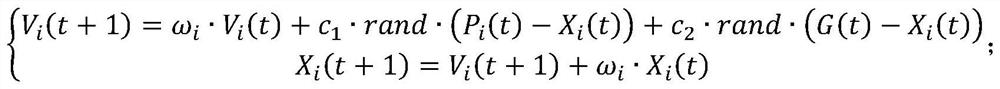

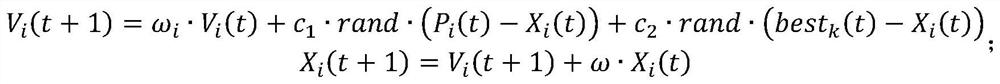

[0060] S1. Set and initialize the main particle swarm and the auxiliary particle swarm, including initializing the dimensions and scales of each swarm, as well as the initial velocity and initial position of each particle, where each particle represents the hyperparameter set of the network structure; set fitness function, and calculate the fitness value of each particle to determine the initial indiv...

Embodiment 2

[0136] A method for predicting an ink drop point error in jet printing, comprising:

[0137] Collect the flight characteristic data of the ink droplet to be predicted, input the LSTM neural network model constructed by a kind of LSTM neural network model construction method for jet printing ink drop point error prediction as described in the first embodiment, the model outputs the jet printing Ink drop point error, to complete the prediction of jet printing ink drop point error.

[0138] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0140] A computer-readable storage medium, the computer-readable storage medium includes a stored computer program, wherein when the computer program is run by a processor, the device where the storage medium is located is controlled to execute the above-mentioned one for spraying An LSTM neural network model construction method for ink drop point error prediction and / or a method for predicting ink drop point error as described above.

[0141] The relevant technical solutions are the same as those in Embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com