Round-corner edge-sealed cellular board and preparation process thereof

A preparation process and technology of honeycomb panels, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve the problems of excessive glue at the joints of edges, irregular groove gaps, and poor structural uniformity of finished products, etc. Achieve the effects of enhancing toughness, reducing collision damage, and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

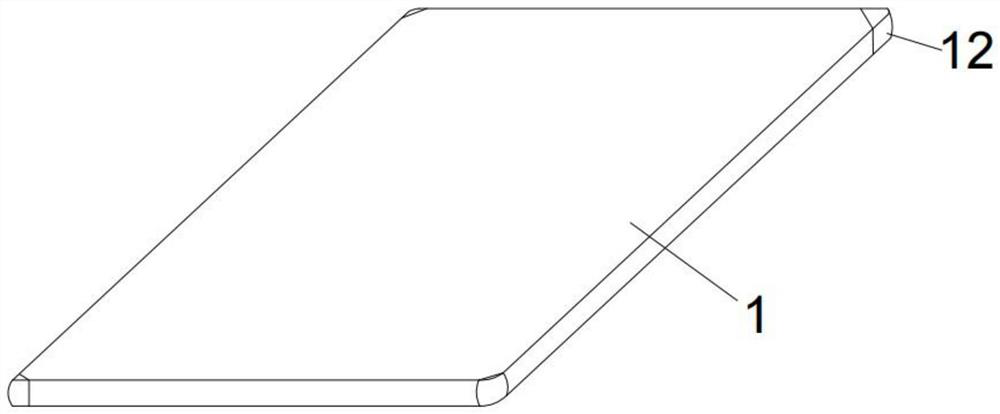

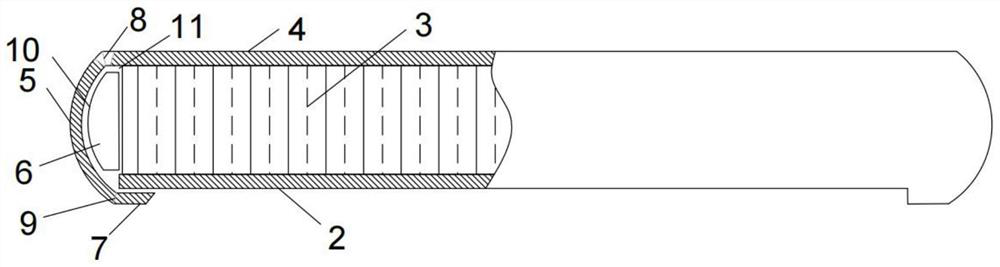

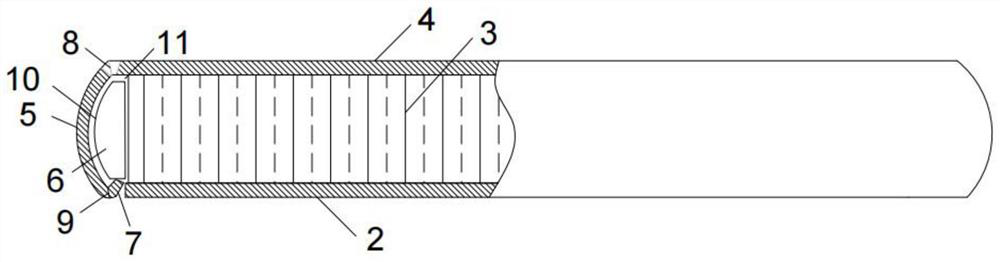

[0040] see Figure 1-4 , a honeycomb panel with rounded edges, comprising a honeycomb panel body 1, the honeycomb panel body 1 includes a bottom plate 2, the top of the bottom plate 2 is bonded with a honeycomb core 3, the top of the honeycomb core 3 is fixedly connected with a top plate 4, and the edge of the top plate 4 The parts are integrally connected with an edge-sealing aluminum plate 5, the inside of the edge-sealing aluminum plate 5 is bonded with a buffer filling block 6, and the edge part of the edge-sealing aluminum plate 5 is integrally connected with an edge-sealing strip 7; 5 is bent, which reduces the use of adhesive colloids, and is more environmentally friendly. The edge-sealing aluminum plate 5 is used for covering, which enhances the overall structural strength, and the buffer pad and the arc-shaped edge-sealing aluminum plate 5 can be used for buffering. The function of shock absorption enhances the toughness of the edge portion of the honeycomb panel body...

Embodiment 2

[0054] A preparation process of a honeycomb panel with rounded edges and edges, comprising the following steps:

[0055] S1. Material preparation: alternatively use the materials of the top plate 4, the bottom plate 2, the buffer filling block 6 and the honeycomb core 3, and pre-prepare the materials;

[0056] S2. Positioning and bending: Position the top plate 4, cut out the incision at the chamfer, and use a punching machine to press to form the first bending line 8 and the second bending line 9, which is convenient for later folding and hemming;

[0057] S3, gluing: place the honeycomb core 3 on the positioning mold, the gluing mechanism moves slowly to apply gluing, and use a scraper to scrape the surface layer of the honeycomb core 3, so that the surface of the honeycomb core 3 is evenly coated with glue ;

[0058] S4, bonding: the top plate 4 and the bottom plate 2 are bonded in sequence, and pressure is applied to the top plate 4 and the bottom plate 2 to make the hone...

Embodiment 3

[0063] A preparation process of a honeycomb panel with rounded edges and edges, comprising the following steps:

[0064] S1. Material preparation: alternatively use the materials of the top plate 4, the bottom plate 2, the buffer filling block 6 and the honeycomb core 3, and pre-prepare the materials;

[0065] S2. Positioning and bending: Position the top plate 4, cut out the incision at the chamfer, and use a punching machine to press to form the first bending line 8 and the second bending line 9, which is convenient for later folding and hemming;

[0066] S3, gluing: place the honeycomb core 3 on the positioning mold, the gluing mechanism moves slowly to apply gluing, and use a scraper to scrape the surface layer of the honeycomb core 3, so that the surface of the honeycomb core 3 is evenly coated with glue ;

[0067] S4, bonding: the top plate 4 and the bottom plate 2 are bonded in sequence, and pressure is applied to the top plate 4 and the bottom plate 2 to make the hone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com