Petroleum production sewage treatment device convenient to clean

A sewage treatment device and petroleum technology, which is applied in the directions of grease/oily substance/float removal device, general water supply saving, separation method, etc., can solve the problems of low treatment efficiency, delayed oil wastewater treatment time, and complicated oil wastewater treatment steps. , to achieve the effect of improving efficiency, reducing precipitation time, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

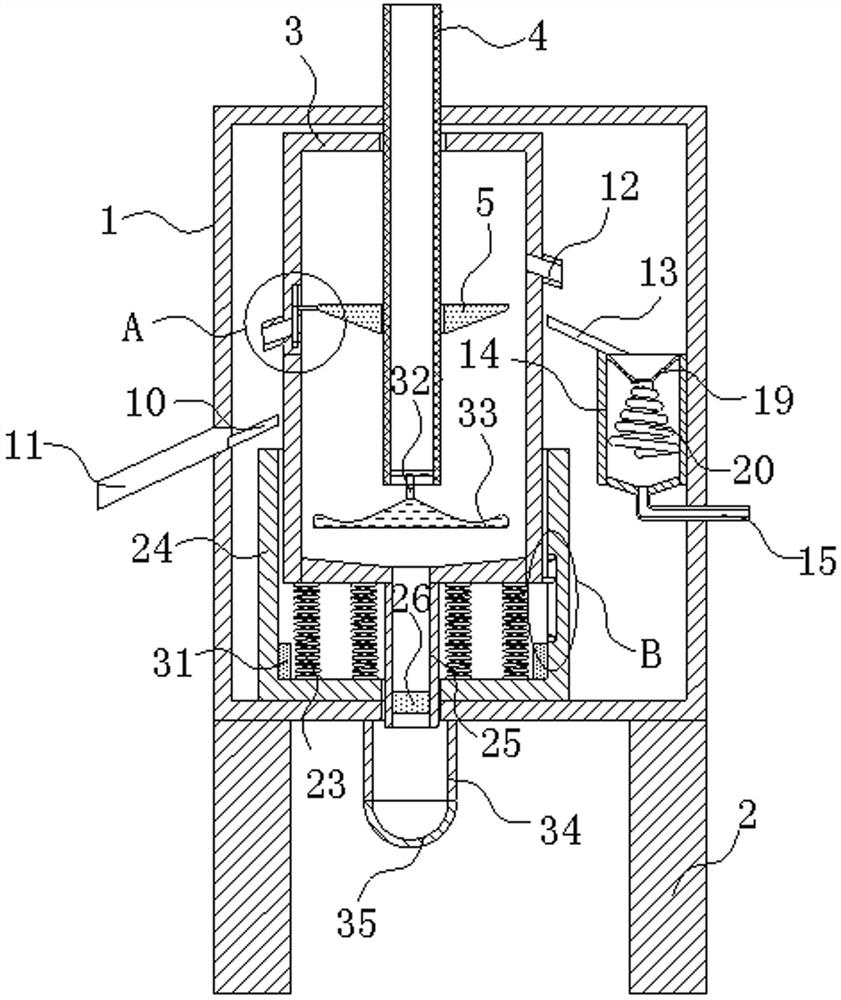

see figure 1 , figure 2 , image 3 , Figure 4 , a sewage treatment device for petroleum production that is easy to clean, comprising a casing 1, a support leg 2 is fixedly connected to the corner of the lower surface of the casing 1, and a mud discharge pipe is arranged at the center of the lower surface of the casing 1 25. The inner upper end of the casing 1 is provided with a processing box 3, and the interior of the processing box 3 is provided with an oil injection pipe 4, and the upper end of the oil injection pipe 4 penetrates the processing box 3 and the casing 1 once and extends to the outside, The outer surface of the oil injection pipe 4 is slidingly connected with the processing box 3, and the outer surface of the oil injection pipe 4 is fixedly connected with the housing 1;

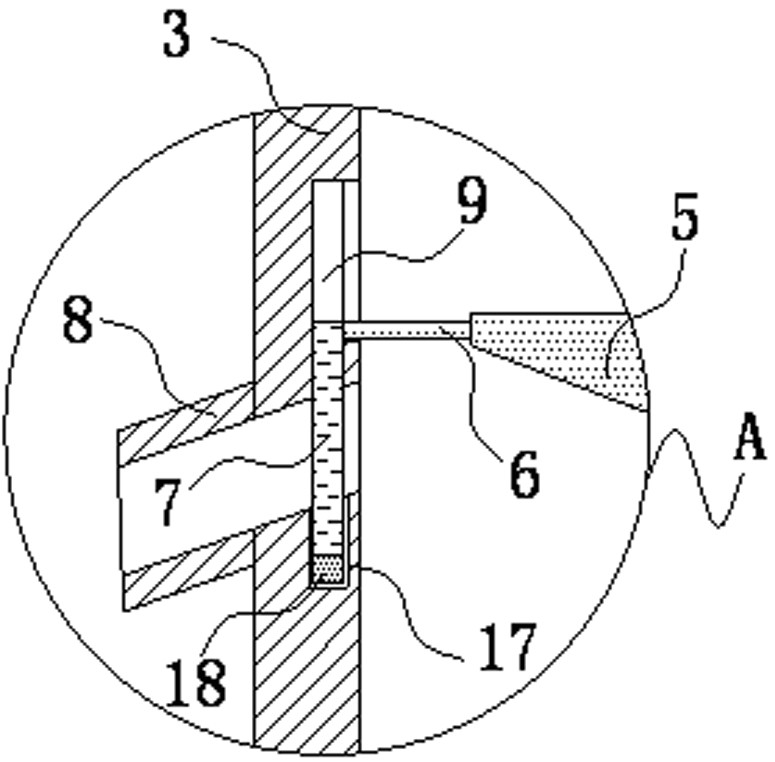

The outer surface of the oil filling pipe 4 is slidably connected with a floating plate 5, the overall density of the floating plate 5 is smaller than the density of water and greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com