Guniting material and preparation method thereof

A technology of spraying and slurry, which is applied in the direction of fireproof coatings, climate sustainability, coatings, etc., can solve the problems of sag resistance, crack resistance and poor weather resistance, and achieve good protection and high elasticity Modulus, effect of airtightness retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

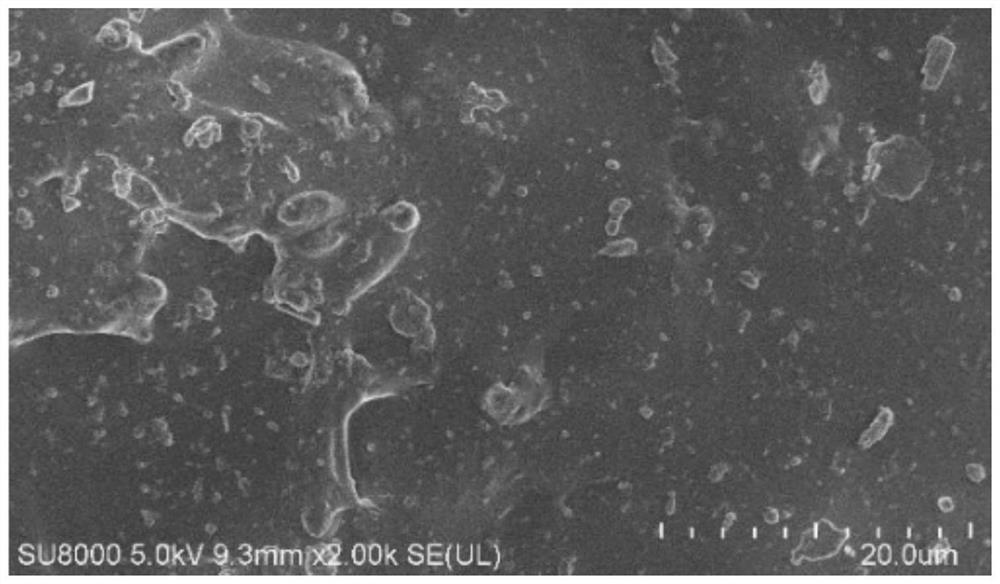

Image

Examples

Embodiment Construction

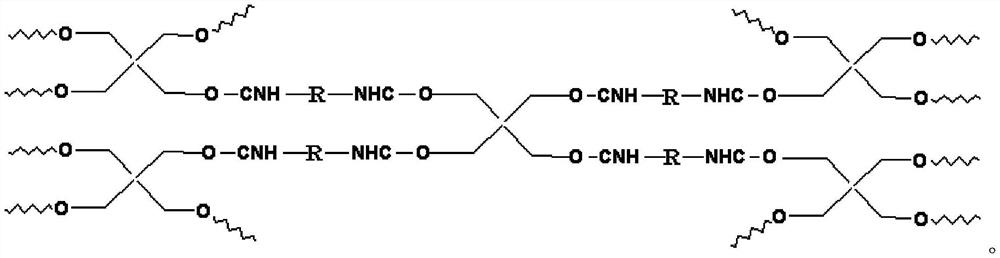

[0027] The present application provides a spraying material, including component A and component B, wherein component A includes the following raw materials by weight: 0.1-0.5 parts of microcapsule polymer material, 1-5 parts of film auxiliary, 1-5 parts of plasticizer, 1-4 parts of waterproofing agent, 0.5-2.5 parts of weathering agent, 10-20 parts of carbonate, 5-10 parts of silicate, 5-10 parts of silica fume,

[0028] Component B includes the following raw materials in parts by weight: 0.1-0.5 parts of inorganic dispersants, 0.1-0.5 parts of organic dispersants, 1-5 parts of film additives, 1-5 parts of plasticizers, 1-4 parts of water repellants, weather resistance 0.5-2.5 parts of antifoaming agent, 0.1-0.5 parts of antifoaming agent, and 0.5-3 parts of reaction repairing agent.

[0029] As the main matrix material in the self-healing shotcrete material system, the microcapsule polymer material determines the basic physical and mechanical properties of the self-healing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com