ASA (Acrylonitrile-Styrene-Acrylate) and PET (Polyethylene Terephthalate) blended alloy and preparation method thereof

A technology of mixing gold and mass parts, which is applied in the field of ASA and PET mixed gold and the preparation of the alloy, can solve the problems of large interfacial tension, difficulty, and thermodynamic incompatibility between the two phases, so as to improve the melt index and improve the tensile strength. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

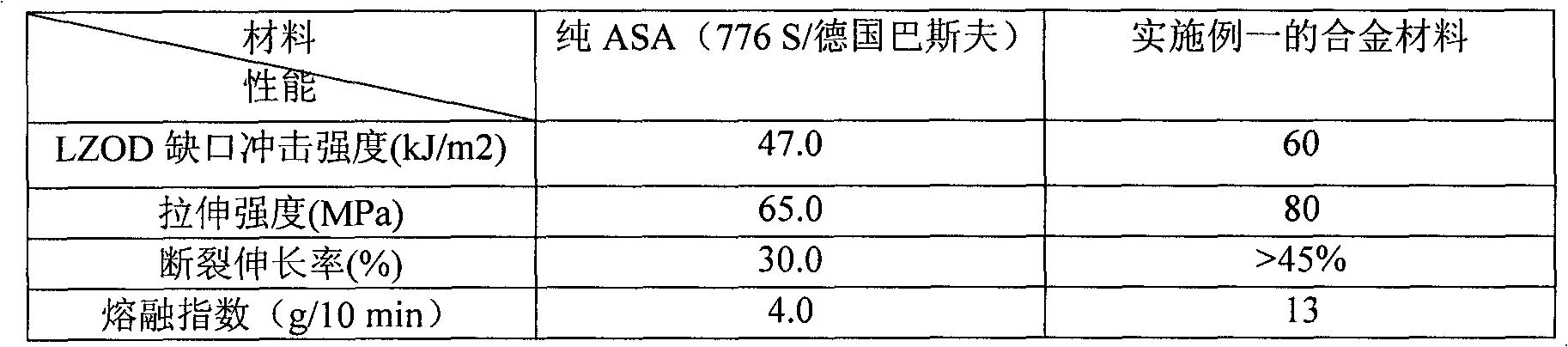

Embodiment 1

[0017] A blended alloy of ASA and PET, which consists of the following components:

[0018] 25 parts by mass of ASA;

[0019] 15 parts by mass of PET;

[0020] The compatibilizer of 0.5 mass parts, in the present embodiment, compatibilizer selects SMA for use;

[0021] The antioxidant of 0.6 mass parts, antioxidant is selected antioxidant 1010 for use in the present embodiment;

[0022] The lubricant of 0.5 mass parts, lubricant selects calcium stearate among the present embodiment.

[0023] The method for preparing the above blended alloy of ASA and PET: mix the raw materials according to the proportion, stir the raw materials evenly, put them into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 190°C and a screw speed of 400rpm.

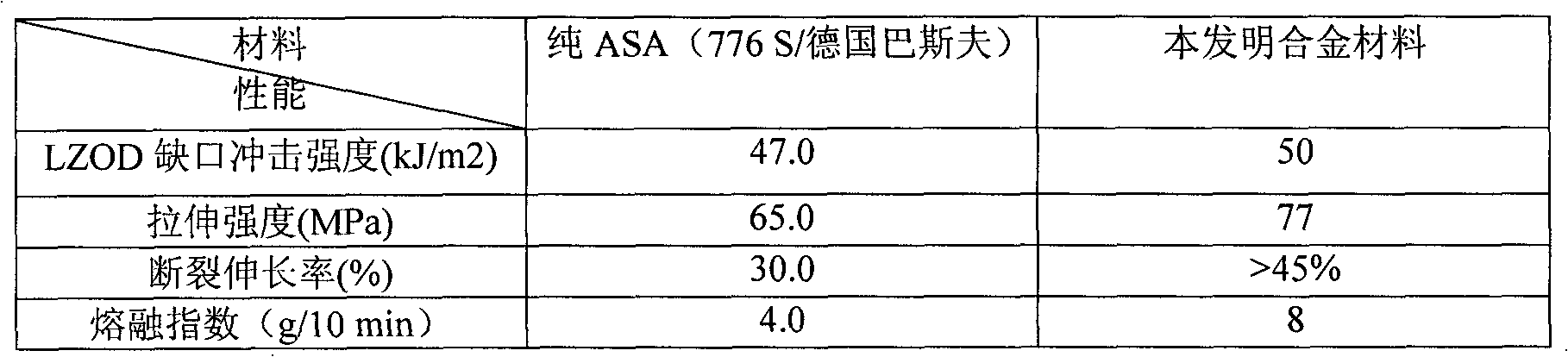

Embodiment 2

[0025] A blended alloy of ASA and PET, which consists of the following components:

[0026] 90 parts by mass of ASA;

[0027] 55 parts by mass of PET;

[0028] The compatibilizer of 3 mass parts, in the present embodiment, compatibilizer selects PS-g-MAH for use;

[0029] The antioxidant of 0.47 mass parts, antioxidant is selected antioxidant 168 for use in the present embodiment;

[0030] 0.75 parts by mass of the lubricant, the lubricant in the present embodiment selects zinc stearate for use.

[0031] The method for preparing the above-mentioned blended alloy of ASA and PET: mix the raw materials according to the proportion, stir the raw materials evenly, put them into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 180°C and a screw speed of 400rpm.

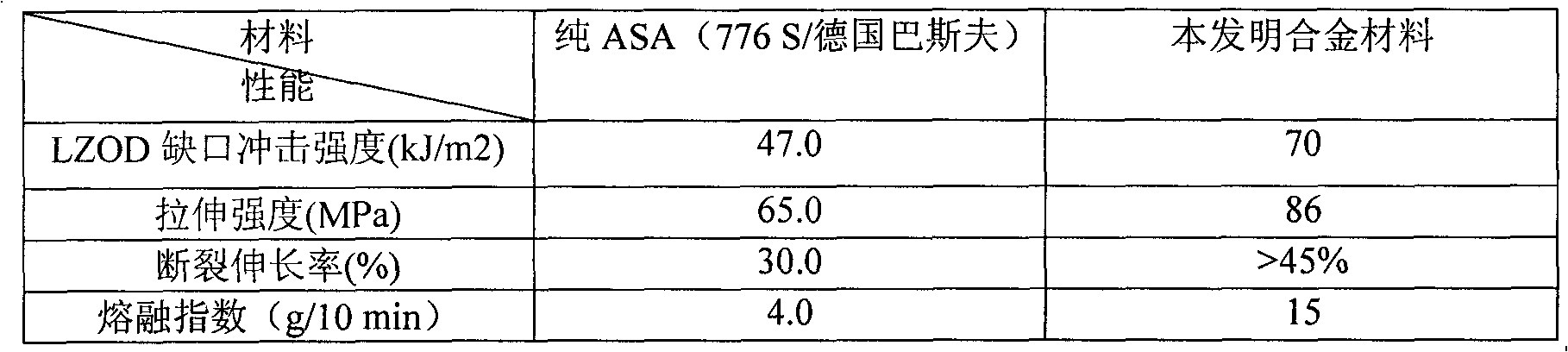

Embodiment 3

[0033] A blended alloy of ASA and PET, which consists of the following components:

[0034] 35 parts by mass of ASA;

[0035] 60 parts by mass of PET;

[0036] The compatibilizer of 0.1 mass part, compatibilizer selects SEBS-g-MAH among the present embodiment;

[0037] The antioxidant of 0.55 mass parts, antioxidant is selected antioxidant 168 for use in the present embodiment;

[0038] 0.6 parts by mass of the lubricant, the lubricant in the present embodiment selects PE wax.

[0039] The method for preparing the above-mentioned blended alloy of ASA and PET: mix the raw materials according to the proportion, stir the raw materials evenly, put them into a twin-screw extruder, extrude and granulate under the conditions of a processing temperature of 200°C and a screw speed of 400rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com