Water-borne fluorine-containing hydroxy acrylic resin and water-borne paint containing the same

A fluorine-containing hydroxy acrylic and hydroxy acrylic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsatisfactory aging resistance, insufficient paint film fullness, poor paint workability, etc., to improve hardness, increase Effect of gloss and aging resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

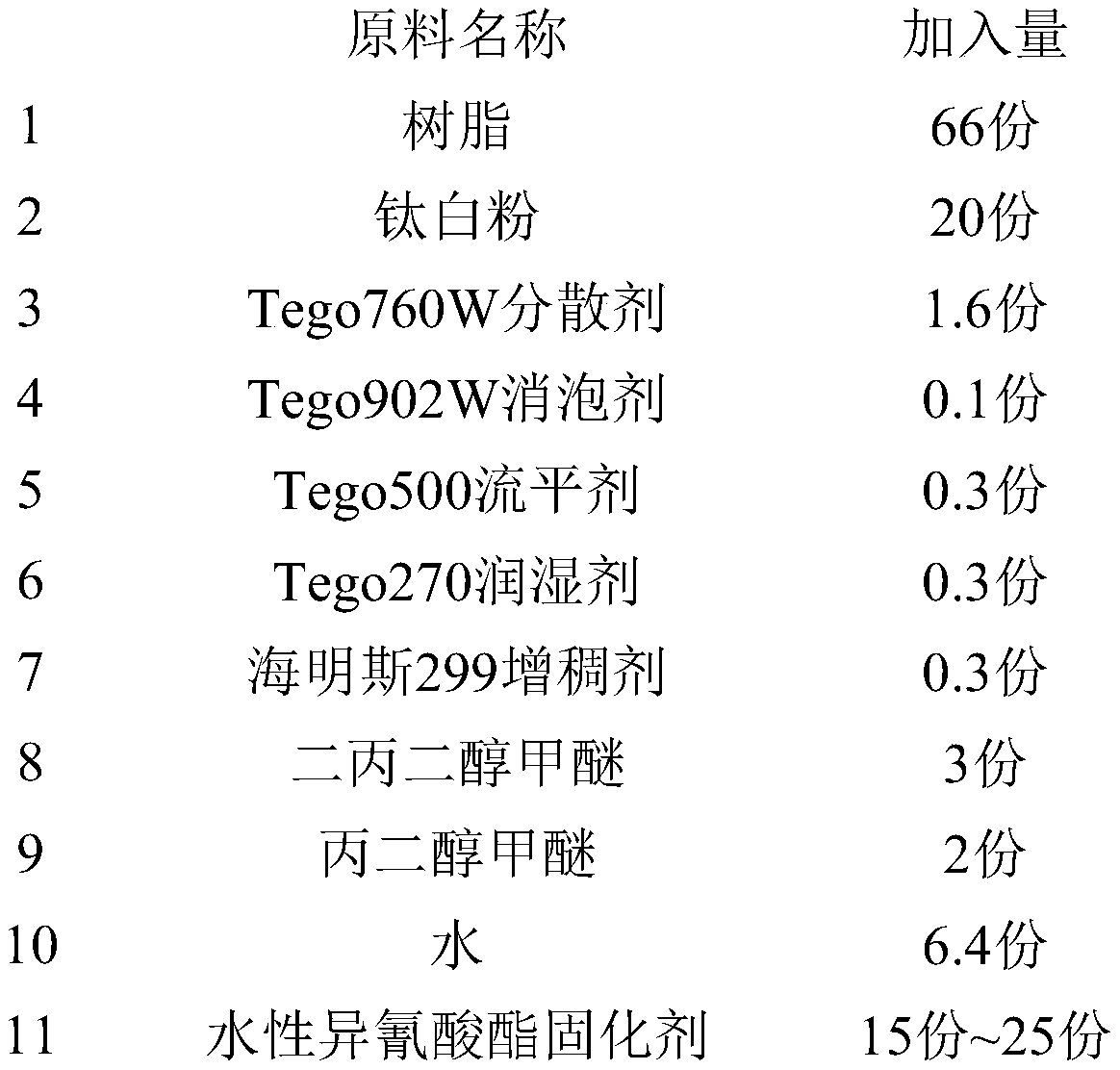

Method used

Image

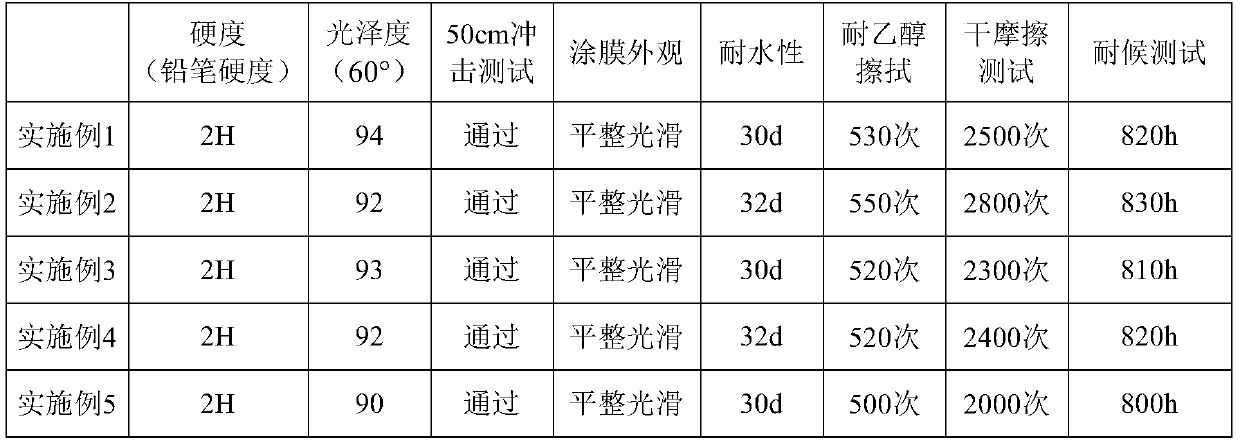

Examples

Embodiment 1

[0052] (1) Add 5 parts of dipropylene glycol methyl ether into a reactor equipped with a condensing device and a stirring rod, and raise the temperature to 105°C. After constant temperature, start to drop the mixed solution (5.35 parts of methyl methacrylate, 5.9 parts of n-butyl acrylate, 1.7 parts of styrene, 7.05 parts of 2-ethylhexyl acrylate, 28 parts of 2-hydroxypropyl acrylate, 2.5 parts of methacrylic acid, 3.53 parts of vinyl tertiary carbonate (VV-10), 2 parts of dodecafluoroheptyl methacrylate, 0.42 parts of dibenzoyl peroxide, 0.1 part of mercaptoethanol), control the dropping rate, at 1.5 After the dropwise addition is completed within 2 hours, continue to keep warm for 2 hours, add 0.18 parts of dibenzoyl peroxide to initiate, continue to keep warm for 3 hours, and measure the conversion rate every half hour until the conversion rate reaches more than 98%. The value was 22 mgKOH / g.

[0053] (2) Lower the temperature of the system to 50°C, control the rotation sp...

Embodiment 2

[0057] (1) Add 6 parts of dipropylene glycol butyl ether into a reactor equipped with a condensing device and a stirring rod, and raise the temperature to 105°C. After constant temperature, start to drop the mixed solution (7 parts of methyl methacrylate, 6.1 parts of n-butyl acrylate, 2.3 parts of styrene, 8.6 parts of isooctyl acrylate, 27 parts of 2-hydroxypropyl methacrylate, 27 parts of methyl 1.9 parts of acrylic acid, 3.6 parts of vinyl tertiary carbonate (VV-10), 2.5 parts of dodecafluoroheptyl methacrylate, 0.56 parts of dibenzoyl peroxide, and 0.2 parts of mercaptoethanol), control the dropping rate at 1.5-2 Dropping is completed within 1 hour, continue to keep warm for 2 hours, add 0.24 parts of dibenzoyl peroxide to trigger, continue to keep warm for 3 hours, measure the conversion rate every half hour until the conversion rate reaches more than 98%, and measure the acid value 20mgKOH / g.

[0058] (2) Lower the temperature of the system to 60°C, control the rotatio...

Embodiment 3

[0062] (1) Add 5.5 parts of n-butanol into a reactor equipped with a condensing device and a stirring rod, and raise the temperature to 105°C. After constant temperature, start to drop the mixed solution (6.8 parts of methyl methacrylate, 6.3 parts of n-butyl acrylate, 2.4 parts of styrene, 8.5 parts of isooctyl acrylate, 25.5 parts of 2-hydroxypropyl methacrylate, methyl 1.6 parts of acrylic acid, 5 parts of vinyl tertiary carbonate (VV-10) containing 10 carbon elements, 1.9 parts of dodecafluoroheptyl methacrylate, 0.49 parts of dibenzoyl peroxide, 0.2 parts of mercaptoethanol), controlled drop Acceleration, the dropwise addition is completed within 1.5 to 2 hours, continue to keep warm for 2 hours, add 0.21 parts of dibenzoyl peroxide after initiation, continue to keep warm for 3 hours, measure the conversion rate every half hour, until the conversion rate reaches 98% As above, the measured acid value was 18 mg KOH / g.

[0063] (2) Lower the temperature of the system to 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com