Fiber forming facility for manufacturing formed part made of environment-friendly degradable fiber material

A fiber forming and degrading fiber technology, used in textiles and papermaking, etc., can solve problems such as incompatibility of intended applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

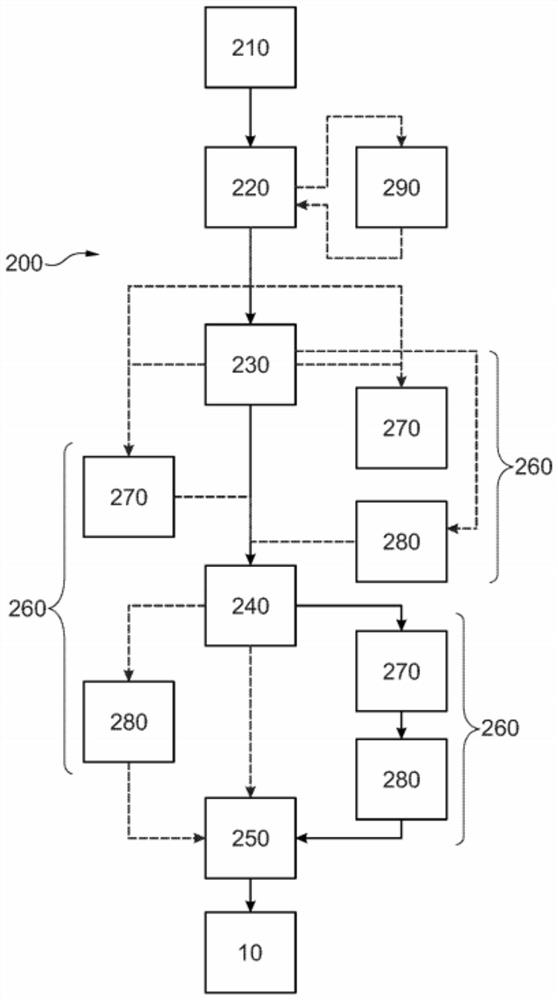

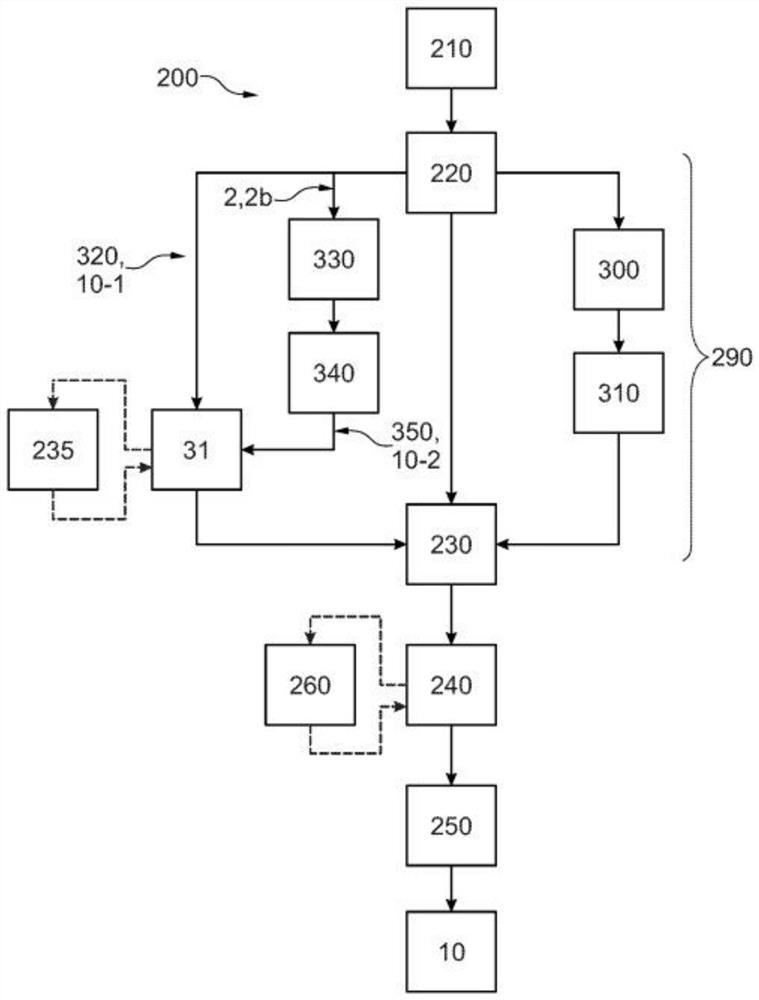

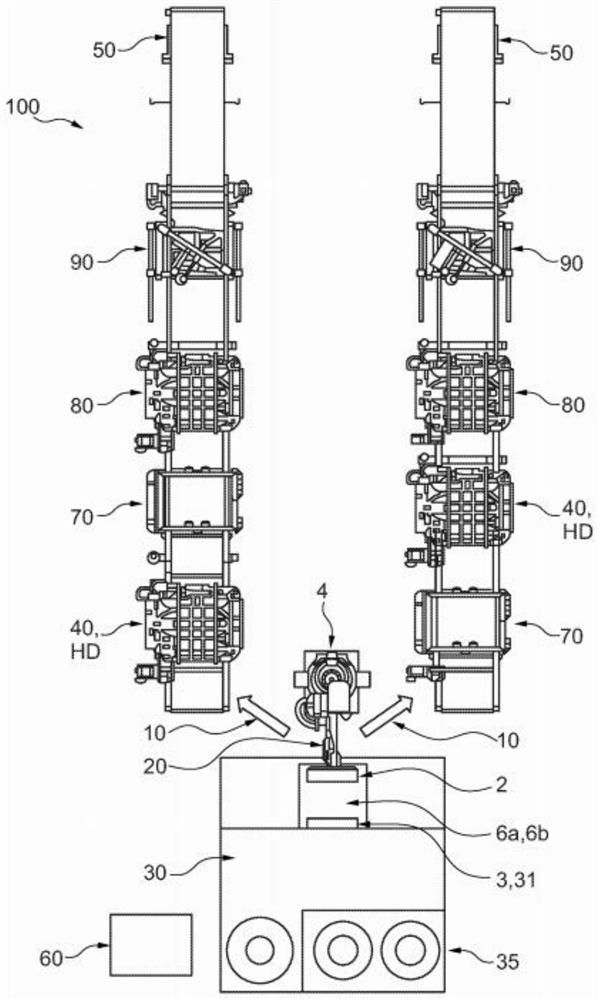

[0095] figure 1 A schematic diagram showing an embodiment of a method 200 for manufacturing a shaped part 10 of environmentally degradable fiber material 11 in a fiber forming facility 100 by a fiber forming process in accordance with the present invention, the method 200 comprising the steps of: The material storage tank 6a provides 210 at least one first slurry 1a as a liquid solution of the environmentally friendly degradable fiber material 11; molding 220 the molded part by dipping the suction mold 2 at least partially into the first slurry 1a for the first time 10, wherein the suction mold 2 comprises several suction heads 21 as a multi-purpose mold, the suction side 21s of the suction head of each suction head 21 in the three-dimensional shape is adapted to the contour of the molded part 10 to be molded, and the suction mold 2 The fibrous material 11 is drawn from the first slurry 1a by means of negative pressure onto the corresponding suction side 21s of the suction he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com