Constant-pressure deep-well pump system and control system and control method thereof

A control system and deep well pump technology, applied in the field of deep well pumps, can solve problems such as pressure instability, impeller wear, and difficult maintenance, and achieve the effects of reducing installation and manufacturing costs, ensuring accuracy, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

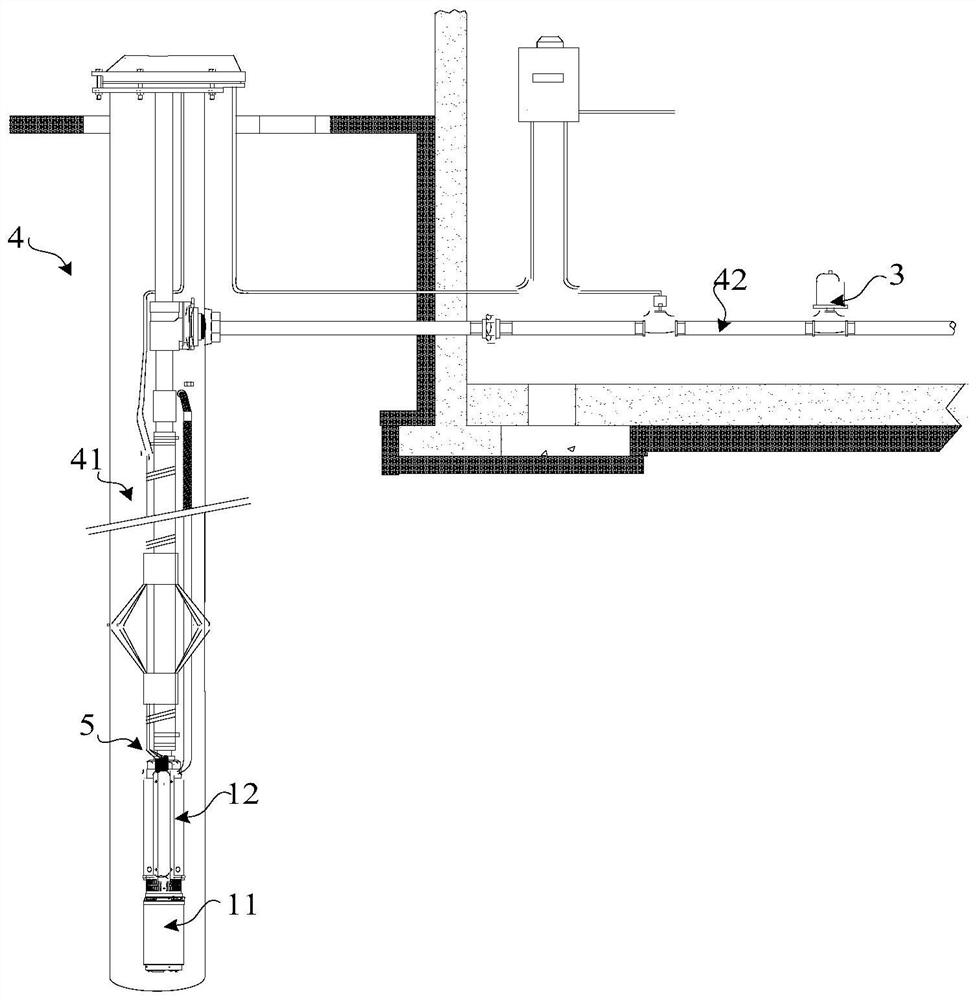

[0027] see attached figure 1 As shown, this embodiment is a constant pressure deep well pump system, which includes a motor 11, a pump body 12 connected to the motor 11 and driven by the motor 11, a pressure sensor 3 disposed in the water supply pipeline 4, and A control system connected to the motor 11 and the pressure sensor 3 . The water outlet of the pump body 12 is connected to the water supply pipeline 4 .

[0028] In some embodiments of the present invention, the control system includes an MCU control chip, which is connected to the motor 11 , and adjusts the rotational speed of the motor 11 according to the pressure in the water supply pipeline 4 . By setting the control box, the MCU control chip can be set in the control box, and the buttons used to control the MCU control chip can be set on the control box. The position of the control box can be adjusted as required, for example, it can be set above the surface for ease of use. The control system of the constant p...

Embodiment 2

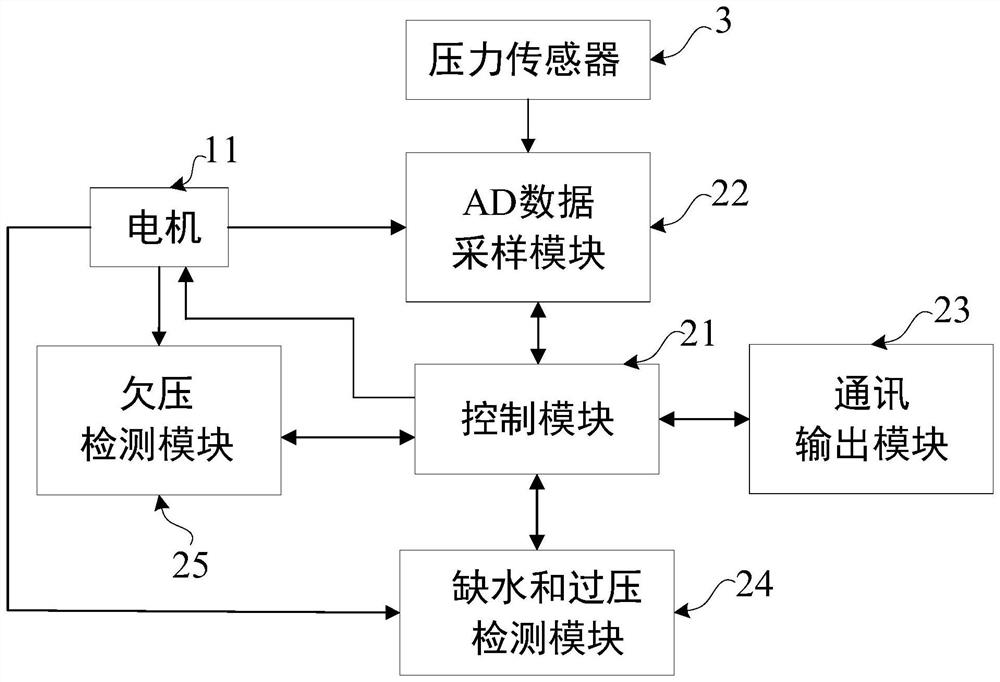

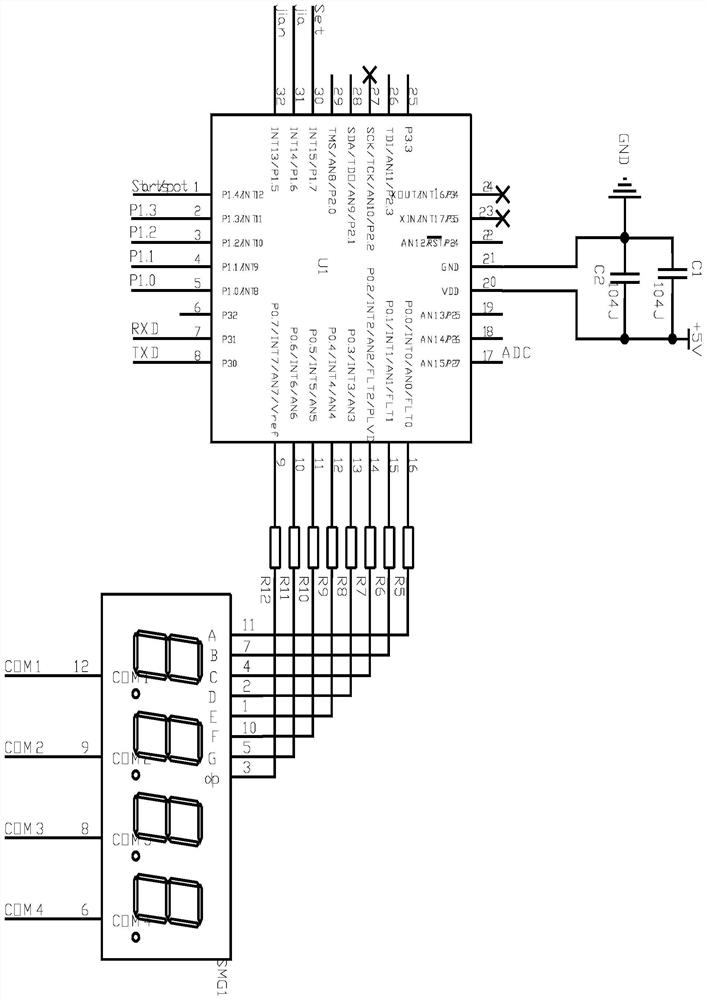

[0045] see attached Figure 2-3 As shown, this embodiment is a control system of a constant pressure deep well pump system, which includes a control module 21, an AD data sampling module 22, a communication output module 23, a water shortage and overload detection module 24, an undervoltage detection module 25, and a control module 25. The module 21 includes an MCU control chip, and the control module 21 is connected to the AD data sampling module 22 , the communication output module 23 , the water shortage and overload detection module 24 , the undervoltage detection module 25 and the motor 11 . The MCU control chip uses 30Pin, 31Pin, 32Pin, and 1Pin as the operation input of the setting key, the addition key, the subtraction key, and the start-stop key, so the pressure value can be set. C1 and C2 are power supply filtering, providing stable and non-interference power supply for MCU. The MCU control chip is used as a digital tube drive port through 2Pin, 3Pin, 4Pin, 5Pin, 9P...

Embodiment 3

[0052] This embodiment is a constant pressure deep well multi-stage pump system, which includes a permanent magnet variable frequency motor 11 , a multi-stage pump body 12 , a pressure sensor 3 arranged in the water supply pipeline 4 , and a variable frequency motor 11 and the pressure sensor 3 are connected. Control System. The control system of the present embodiment is the control system of the second embodiment. The motor 11 of the constant pressure deep well multi-stage pump system of the present embodiment is small in size and high in efficiency, and the hubs of the impellers 71 at all levels are not prone to wear and have a long service life; And use the pressure in the water supply pipeline 4 to realize the start and stop of the motor 11, ensure the stability of the pressure in the water supply pipeline 4 with low power consumption, and reduce the use volume of the pressure tank that is matched with the deep well pump. , can play the effect of energy saving and emissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com