Method for determining phase content in iron ore

A technology of iron ore and phase, applied in the field of determination of phase content in iron ore, can solve the problem that the phase phase diffraction intensity is not proportional to the content, it is difficult to popularize and apply, the external standard does not match the matrix of the sample to be tested, etc. problem, to achieve the effect of expanding the linear range and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] 1.1 Instrument and test conditions

[0064] X-ray diffractometer PANalytical Empyrean, diffraction source Cu Ka, tube pressure 45kV, tube flow 40mA, goniometer radius 240mm. Glass plate sample preparation, filling depth 0.5mm. Step scan mode, step 0.0131°, point scan time 43.10s, 2θ angle range 10-80°, PHD 45-70%. The reagents used in the preparation of standard samples were all excellent grades, and an electronic balance with a sensitivity of 0.000lg was used. All tests were measured on two parallel slices.

[0065] 1.2 Reference materials and samples

[0066] Grind the raw materials until they all pass through a 200-mesh standard sieve, and dry them in a muffle furnace at 105° C. for 1 hour before use.

[0067] 1.3 Standard sample

[0068]

[0069]

[0070]

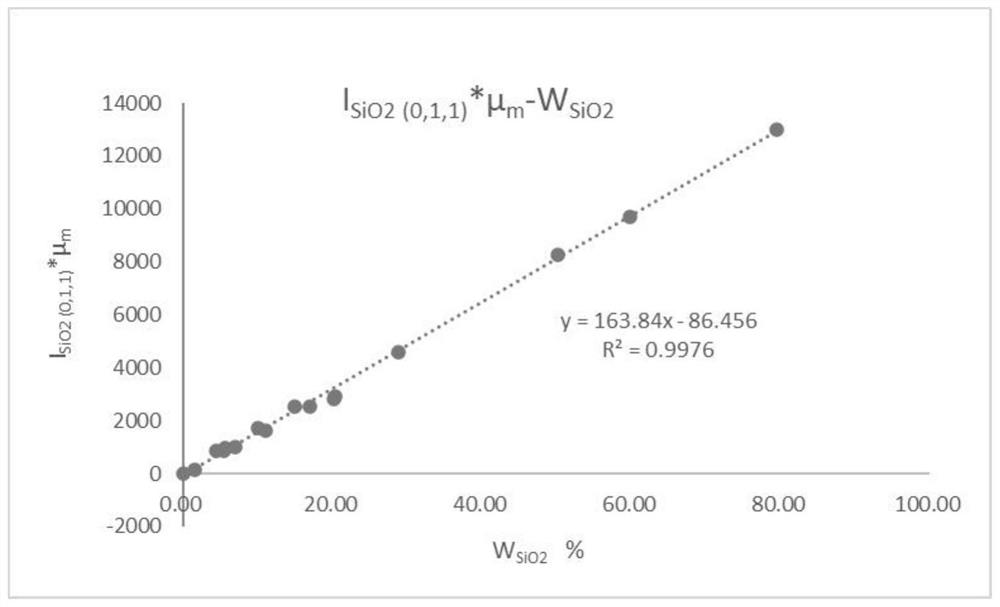

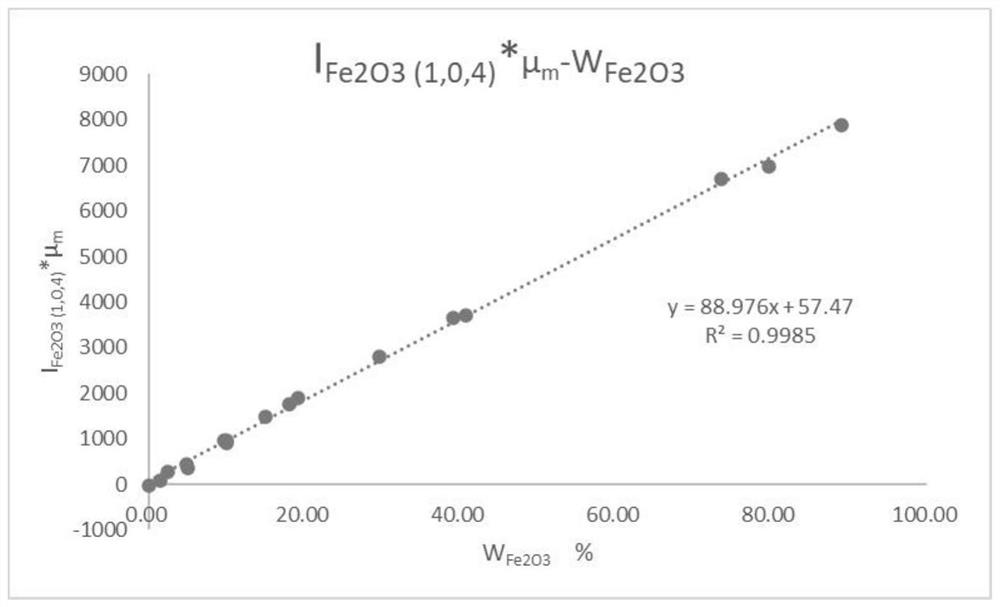

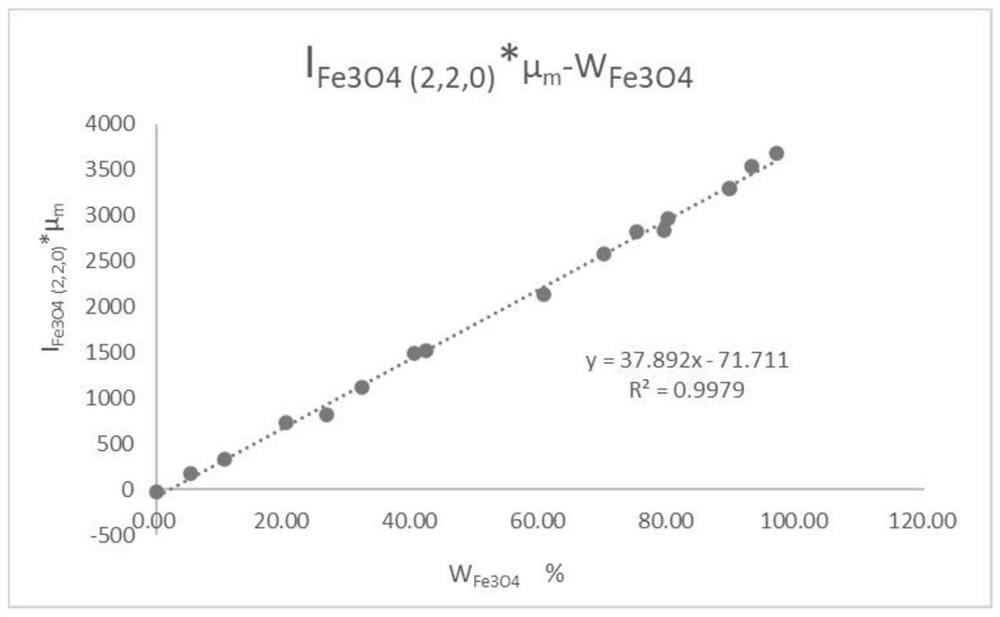

[0071] 1.4 Working curve

[0072]

[0073] 1.5 Sample Test

[0074]

[0075]

[0076] The method for determining the phase content in iron ore can provide a standard sample with a high de...

example 2

[0078] External standard method: Xin Yanqing used X-ray diffraction-external standard method to quantitatively analyze the phase of zinc oxide and yttrium oxide powder mixture, which verifies the application of external standard method in the test of two-phase mixture. Wu Jianpeng established X-ray diffraction-external standard method phase quantification standard curves for 9 components commonly used in inorganic non-metallic materials such as quartz and corundum. Each curve was established based on a two-phase gradient mixture. The external standard method is affected by the mass absorption coefficient. In the multiphase test, the reference material needs to be completely matched with the matrix of the sample to be tested. In theory, it is impossible to have the same phase composition and content as the sample to be tested. The influence of the mass absorption coefficient results in a narrow application range of the external standard method, which is suitable for samples comp...

example 3

[0080] Full spectrum fitting method: Zeng Ling used X-ray diffraction-Rietveld full spectrum fitting method to analyze Fe in iron ore 2 O 3 , FeOOH, SiO 2 , A1 2 (Si 2 O 5 )(0H) 4 The composition of a total of 4 kinds of mineral phases, their contents are 86.20%, 9.59%, 3.58%, 0.64%, respectively. The full spectrum fitting method is a method to obtain the content of each phase when the theoretical spectrum is corrected by adjusting the experimental parameters, peak shape parameters, etc., according to the structural data of each phase, so that the theoretical spectrum matches the measured spectrum to the greatest extent possible. The full spectrum fitting method is essentially a semi-quantitative method. It is a theoretical guess. First of all, it is necessary to accurately and qualitatively analyze all the phases in the sample. This is difficult to achieve in real mineral samples. The composition of natural minerals is very complex, and low-content phase diffraction The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com