Logistics material warehouse-in and warehouse-out management method and system

A management method and in-out technology, applied in the field of logistics material in-out management, can solve the problems of easy counting errors, high maintenance costs, inability to locate tracking and accountability, and reduce material loss, reduce corporate losses, and prevent human cheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation or replacement based on the teachings of the present invention belongs to the protection scope of the present invention.

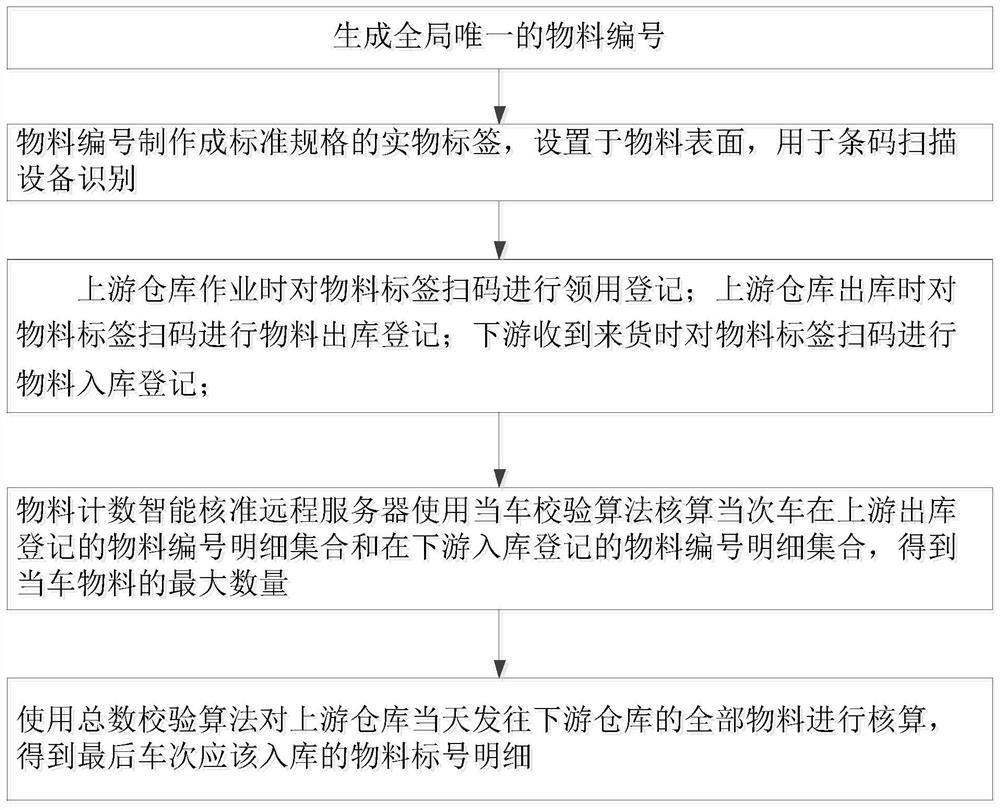

[0027] The steps of the material in-out warehouse management method disclosed by the present invention are as follows:

[0028] S1: Material number generation The remote server provides a deterministic generation rule to ensure that each material number is globally unique in the system, and can also indicate the type of material, such as turnover basket, pier board, incubator, etc., to indicate the entity to which it belongs and the associated Other more information, such as production batch, etc.;

[0029] S2: Each number generated will be made into a standard physical label, such as strong stickers, metal sheets and other materials, which are used to attach or fixedly install on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com