Power demand response method based on discontinuous production process and storage capacity of cement enterprise

A power demand response and production process technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve problems such as unawareness of the energy saving potential of renewable energy and cement time allocation, and achieve source-load interaction and coordination. Synergies, reduces dependencies, enhances intermittent and volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

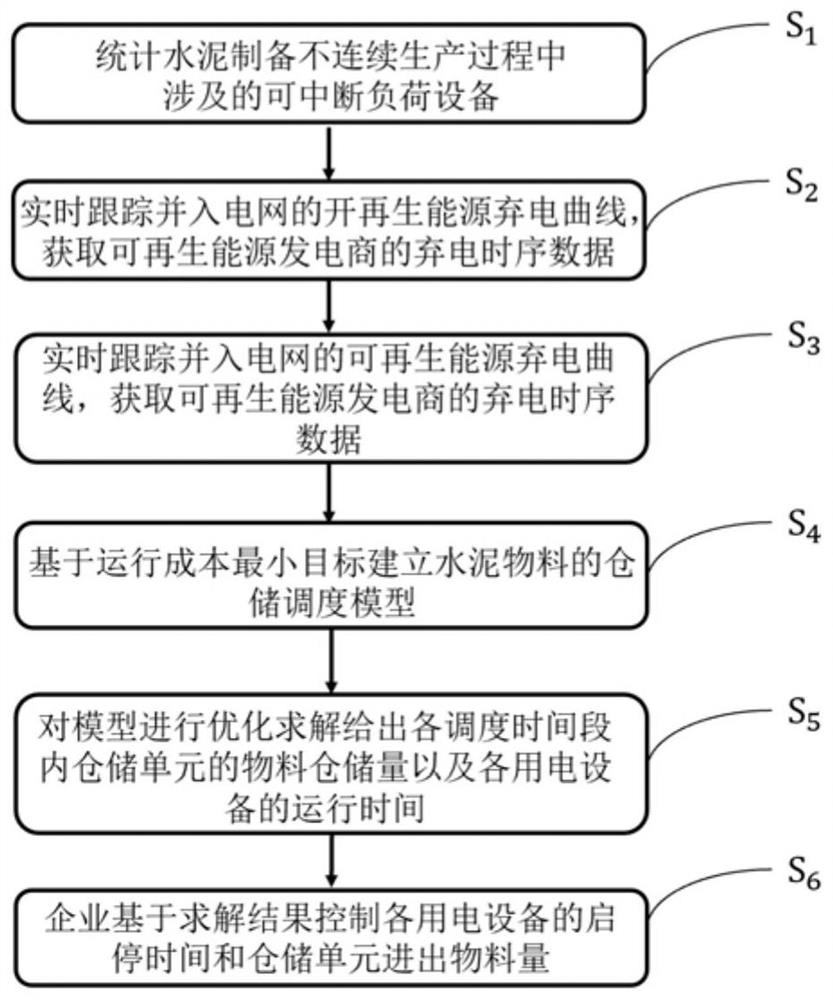

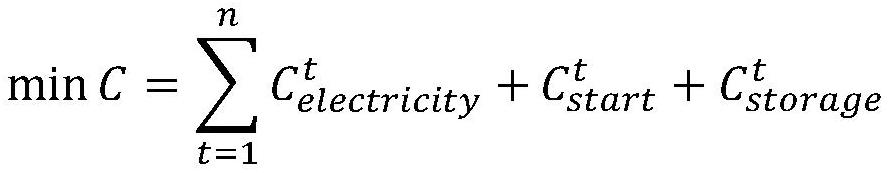

[0079] A power demand response method based on the discontinuous production process and storage capacity of a cement enterprise of the present invention comprises the following steps:

[0080] In step S1, the electricity load in the cement enterprise is divided into interruptible load and non-interruptible load, and the processes and equipment involving the interruptible load are counted.

[0081] In step S11, the electricity load in the cement enterprise is divided into interruptible load and uninterruptible load, wherein the uninterruptible load refers to the electric equipment that operates continuously throughout the day or within a fixed period of time, and the interruptible load refers to the electricity consumption time. The segment can be disconnected from the electrical equipment.

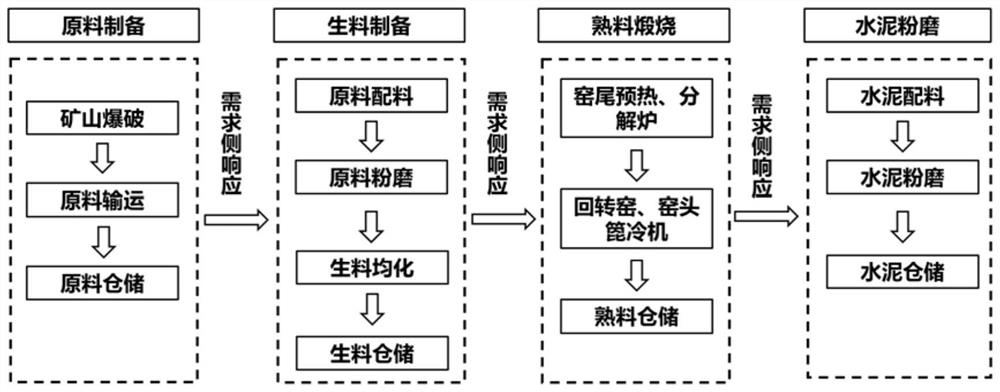

[0082] Step S12, count the processes and equipment that can interrupt the load, and the processes mainly include raw material preparation, raw meal preparation, clinker calcination and cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com