Composite elastic yarn, elastic fabric, and method for manufacturing composite elastic yarn

A manufacturing method and elastic yarn technology, applied in fabrics, textiles, papermaking, yarns, etc., can solve the problems of wrinkling raw yarn and fabric production technology that have not been developed for stretchable fabrics, and achieve improved elastic recovery characteristics and shape maintenance Features, comfort in use, effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

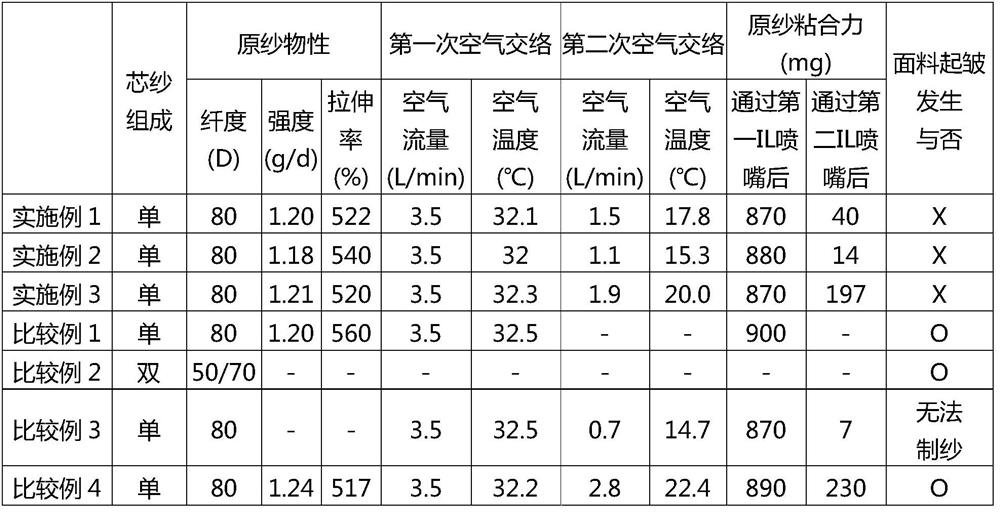

[0052] The raw spandex fiber yarn used as the core yarn of the composite elastic yarn was produced by the following method. The high temperature in the spinning drum makes the raw spandex fiber in a heated state after spinning, which is suitable for causing the kink of the raw yarn and is drawn out. At this time, air is supplied through the first interlacing nozzle, and the adhesive force between the filaments of the original spandex fiber is 870 mg, which belongs to the range of the 80D general spandex fiber adhesion value. After that, the bonding force between the filaments of the original spandex fiber yarn was measured as 5% of the bonding force value of 800 mg of the general spandex fiber of 80D by imparting low temperature and low pressure air through the second air interlacing nozzle during the crimping process. of 40mg.

[0053] As the hard yarn, cotton yarn with a count of 16 is used, and the low-adhesion elastic core yarn produced above is used as the core yarn. Th...

Embodiment 2

[0057] The core yarn of the composite elastic yarn used in the manufacture of denim fabrics is suitable for elastic yarns with low adhesion between filaments. At this time, the adhesive force between the filaments of the spandex fiber raw yarn after passing through the first interlacing nozzle is 880 mg, which belongs to the range of the 80D general spandex fiber adhesion value. After passing through the second air interlacing nozzle, the spandex fiber raw yarn is The inter-filament adhesion was measured to be 14 mg as 2% of the adhesion value of 700 mg of 80D general-purpose spandex fiber.

[0058] The composite elastic yarn and fabric were produced in the same manner as in Example 1 except that the core yarn was different as described above, and the physical properties were evaluated and the results are shown in Table 1.

Embodiment 3

[0060] The core yarn of the composite elastic yarn used in the manufacture of denim fabrics is suitable for elastic yarns with low adhesion between filaments. At this time, the adhesive force between the filaments of the spandex fiber raw yarn after passing through the first interlacing nozzle is 870 mg, which belongs to the range of the 80D general spandex fiber adhesion value. After passing through the second air interlacing nozzle, the spandex fiber raw yarn is The inter-filament adhesion was measured to be 198 mg which is 22% of the adhesion value of 900 mg of 80D general purpose spandex fiber.

[0061] The composite elastic yarn and fabric were produced in the same manner as in Example 1 except that the core yarn was different as described above, and the physical properties were evaluated and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com