Stirling refrigeration system and refrigerator

A refrigeration system and refrigeration machine technology, applied in refrigerators, refrigeration components, household refrigerators, etc., can solve problems such as constraints, and achieve the effects of promoting flow, improving heat dissipation, and isolating noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following description, the orientations or positional relationships indicated by "front", "rear", "upper", "lower", "left", "right", etc. are orientations based on the refrigerator 100 itself as a reference, such as Image 6 the direction indicated.

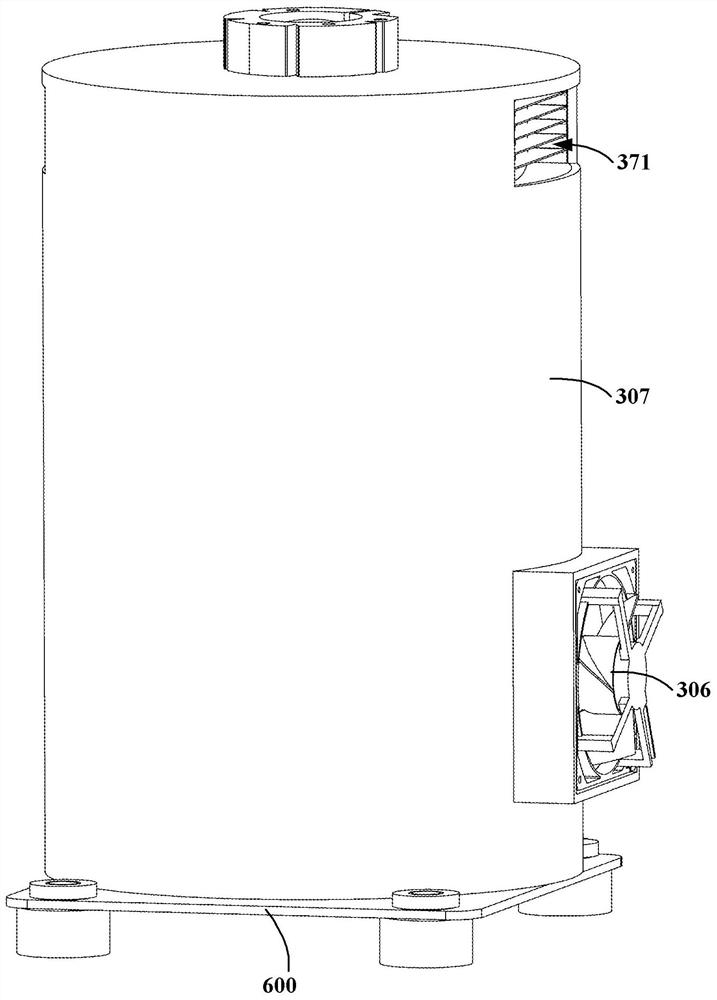

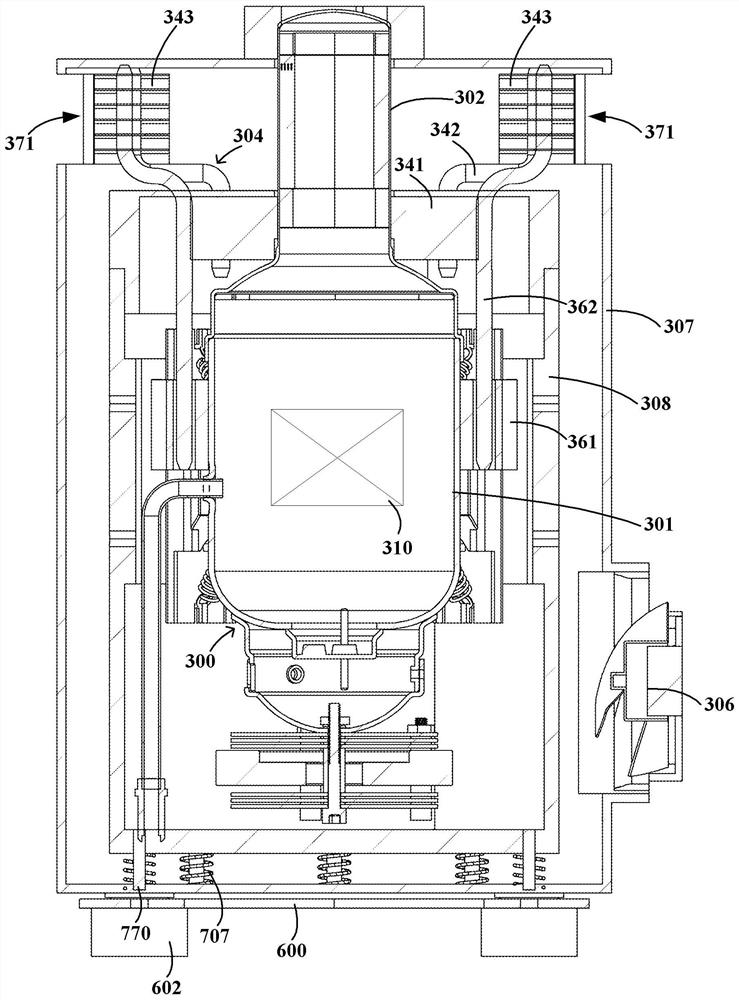

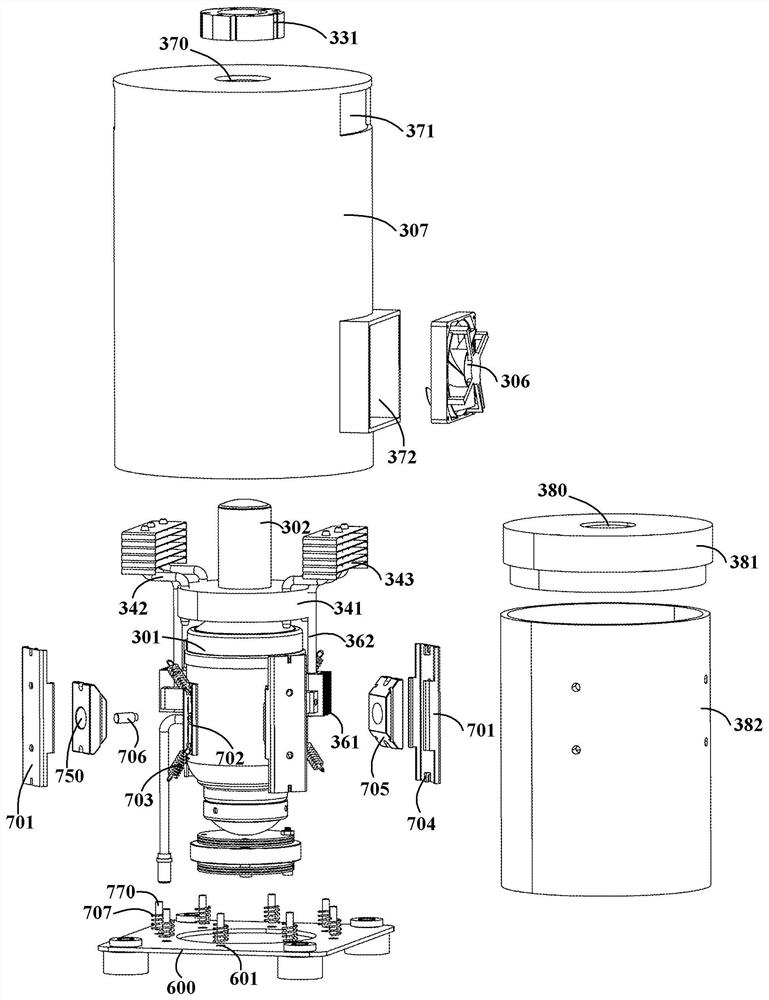

[0047] figure 1 It is a three-dimensional schematic diagram of a Stirling refrigeration system according to an embodiment of the present invention. figure 2 is a schematic cross-sectional view of the Stirling refrigeration system shown in Figure 1. image 3 Yes figure 1 Schematic illustration of the exploded decomposition of the Stirling refrigeration system shown. Figure 4 It is a schematic cross-sectional view of a Stirling refrigeration system according to another embodiment of the present invention. Figure 5 It is a schematic cross-sectional view of some components of a Stirling refrigeration system according to another embodiment of the present invention.

[0048] like Figure 1 to Figure 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com