Graphite heat exchanger with cage type drawable baffling ring group

A technology of graphite heat exchanger and graphite heat exchange block, which is used in indirect heat exchangers, heat exchanger shells, heat exchange equipment, etc. The problems of uneven annular gap of heat block, corrosion and expansion of metal baffles, etc., can avoid the damage of graphite heat exchange elements, reduce the manufacturing size variation, and achieve the effect of high assembly qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

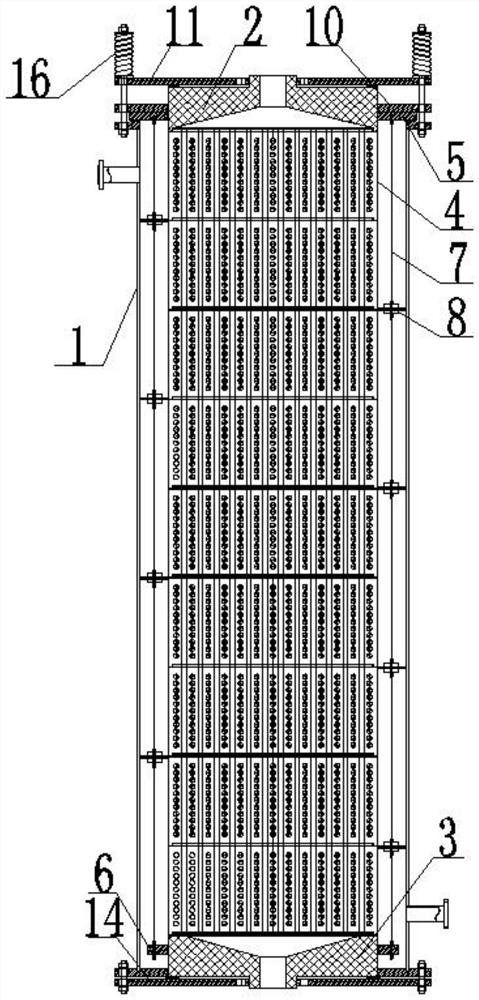

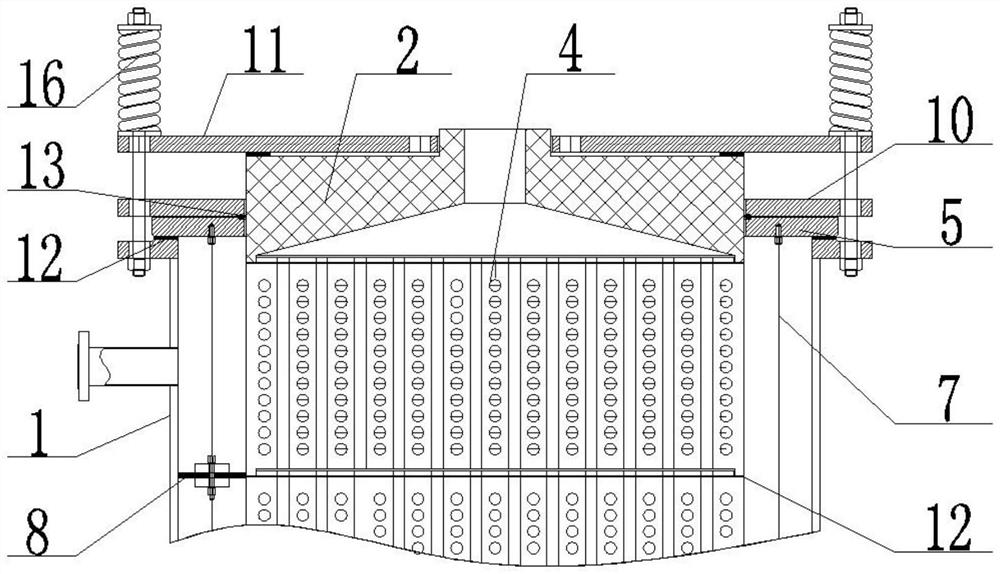

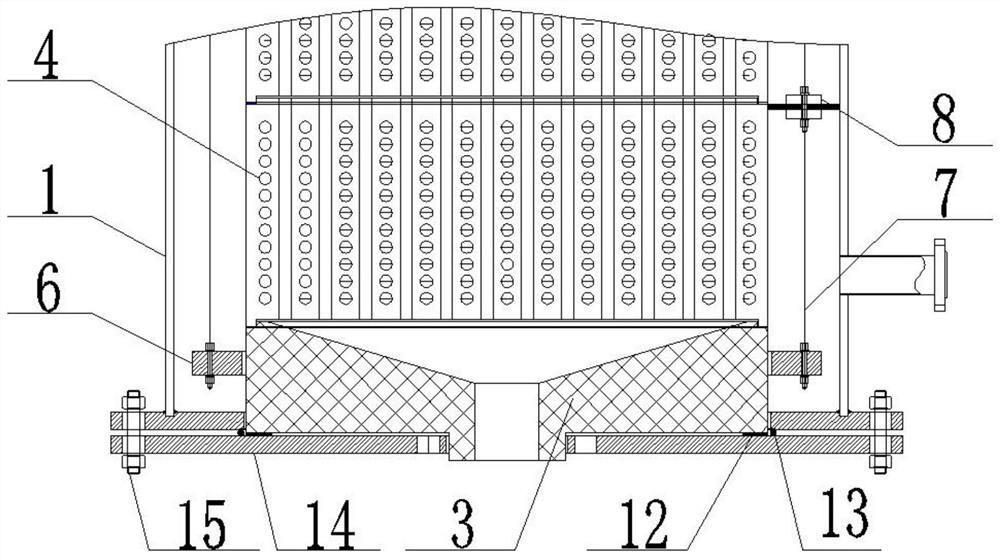

[0034] The embodiment of the present invention: a graphite heat exchanger provided with a cage-type drawable baffle ring group, as shown in the attached Figure 1-6As shown, it includes a cylinder body 1, and the top and bottom of the cylinder body 1 are provided with a graphite upper sealing head 2 and a graphite lower sealing head 3, and the cylinder body 1 between the graphite upper sealing head 2 and the graphite lower sealing head 3 is provided with a A cylindrical body formed by overlapping several graphite heat exchange blocks 4, an annular diversion water jacket is formed between the cylindrical body and the inner wall of the cylinder body 1, and a cage-type drawable baffle ring group is arranged in the annular diversion water jacket. The baffle ring group includes a baffle ring group upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com