Method for controlling thickness of variable-cross-section casting slag bath in electroslag smelting casting

An electroslag casting and thickness control technology, which is applied in the field of electroslag casting slag pool control and electroslag casting variable cross-section casting slag pool thickness control, can solve problems such as no thorough solution has been proposed, and achieve large adjustment space and adapt to process adjustment the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

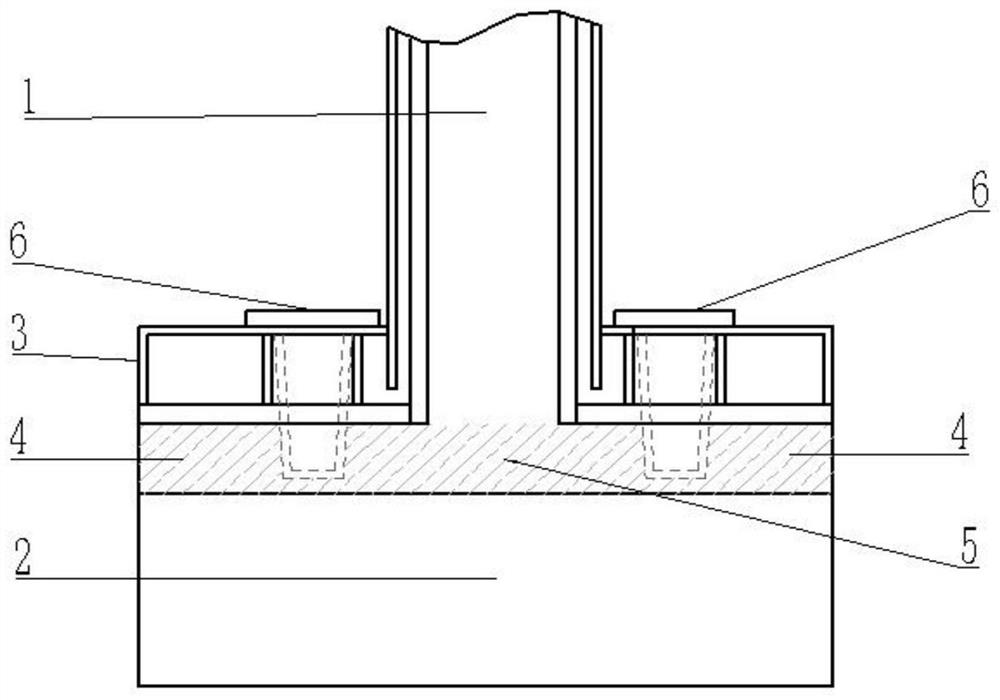

[0032] The turbine guide vane products are selected and manufactured by electroslag casting process. The blocking mold realizes the control of the thickness of the slag pool of electroslag casting with variable cross-section castings, such as figure 1 shown;

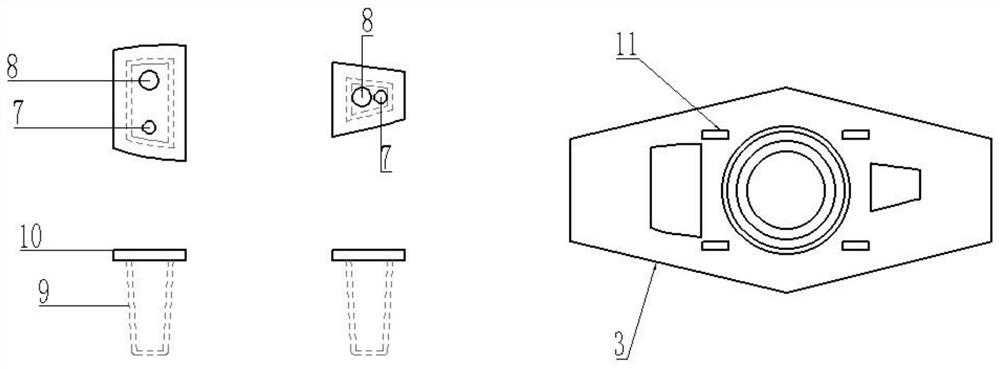

[0033] (1) According to the shape, size and technical requirements of the guide vane, design the amount of process allowance, determine the size of the crystallizer cavity, and apply a blocking crystallizer at the position of the valve body to the long axis transition surface;

[0034] (2) Set aside 2 installation holes for the blocking type crystallizer on the base of the upper crystallizer, apply 2 blocking type crystallizers, and divide the slag pool of the valve body area (large cross-sectional area) into 3 parts, and the middle part is the transition area. When casting is carried out, the slag pool transitions to the long-axis area (small cross-sectional area), and the two sides are non-transition areas. With the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com