A secondary well formation method for energy storage wells in aquifers

An aquifer and energy storage technology, applied in wellbore/well components, drilling equipment and methods, drilling equipment, etc., can solve the problems of heat loss, insufficient strength, resistance to the promotion of aquifer energy storage technology, etc., to improve the use of Longevity, effect of generating heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

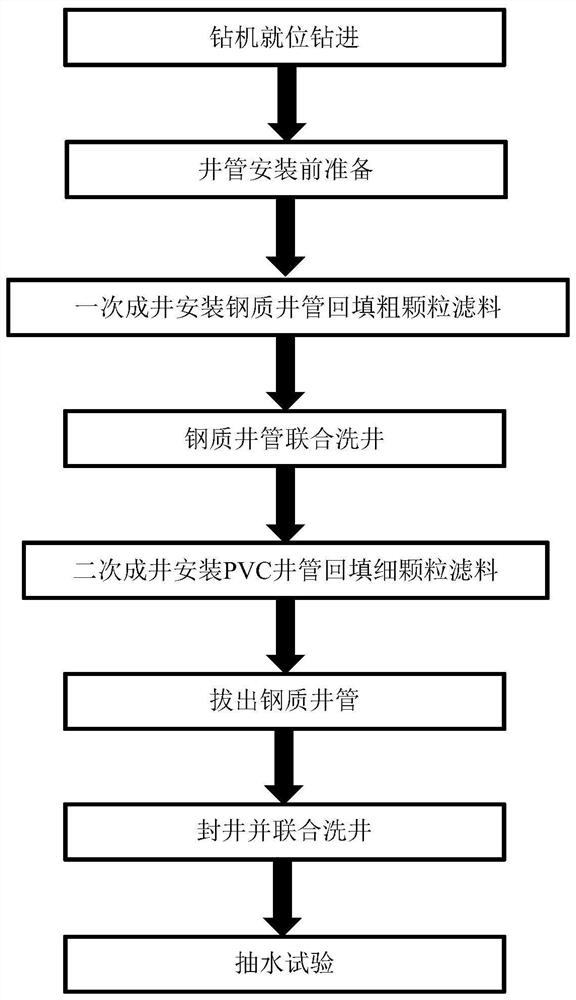

Method used

Image

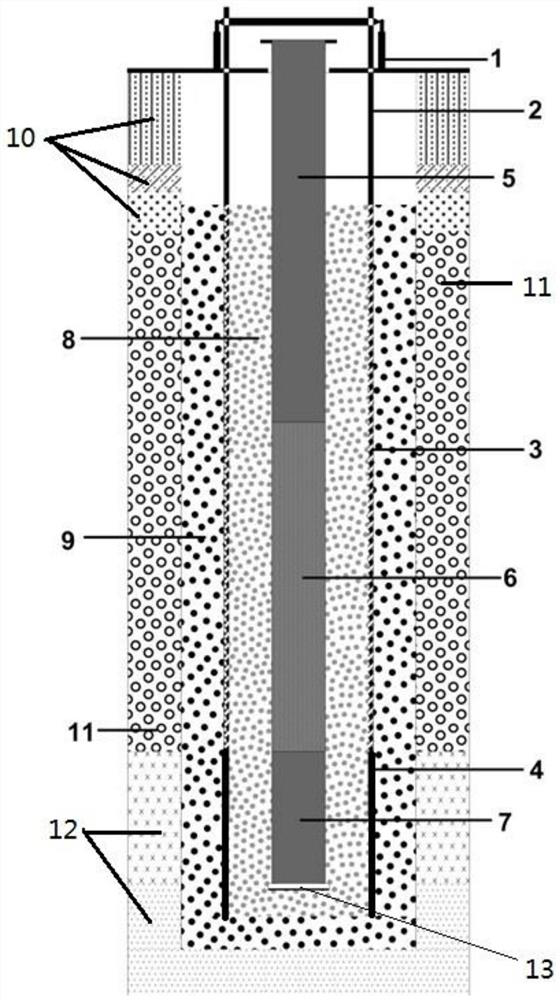

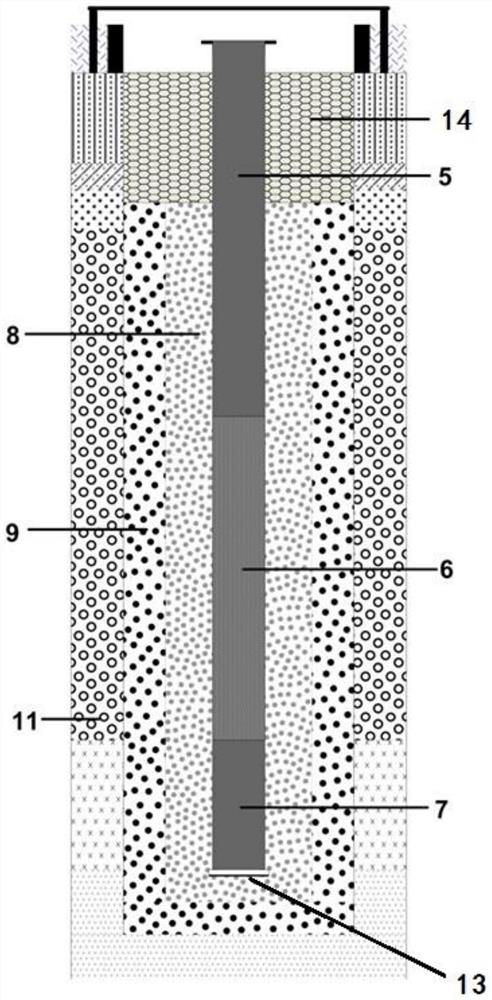

Examples

Embodiment

[0034] Example: Well completion method test for an energy storage well project

[0035]The groundwater type of the proposed site is pore water in the Quaternary loose accumulation layer, and the lithology of the aquifer is mainly round boulders, with strong water permeability and water richness. According to the data in this area, the average permeability coefficient K of the pebble layer is about 80m / d, and the water inflow of a single well is about 50m3 / h. According to the geological characteristics of the site: the main aquifer is round gravel, the maximum particle size is 80mm, and rocks have been seen at about 10 meters. Combined with economic factors, it is known that both positive circulation and reverse circulation are not suitable for energy storage wells in this site Drilling, so the energy storage well drilling method is chosen as percussion drilling.

[0036] 1. Using the traditional one-time well-forming method, after the completion of the well, the energy storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com