A kind of wind power generator brush and preparation method thereof

A brush and pressure technology, which is applied in the manufacture of brushes, motor generator connectors, circuits, etc., can solve the problems of poor wear resistance and short service life of wind brushes, and achieve good wear resistance, long service life, and improved The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

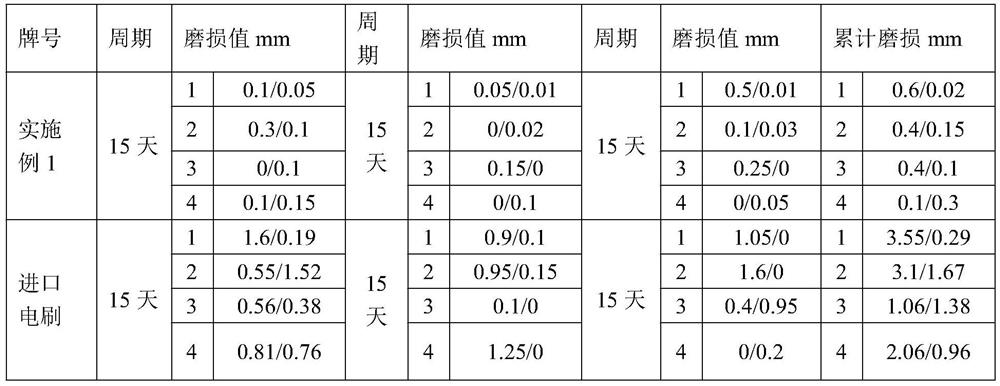

Embodiment 1

[0031] Embodiment 1: A wind power generation brush according to the present embodiment is prepared from 34 parts of graphite powder, 65 parts of silver powder, 5 parts of lead oxide powder, 8 parts of nickel powder, 0.3 parts of antiwear agent and 23 parts of phenolic resin in parts by mass Wherein the graphite powder is flake graphite powder, the average particle diameter is 300 mesh, the carbon content ≥ 99%, and the ash content ≤ 1%; the antiwear agent is silicon carbide, and the average particle diameter of silicon carbide is 300 mesh, so The particle size D50 of the silver powder is 15 μm.

preparation Embodiment 1

[0032] The method for preparing the wind power generation brush described in Example 1 is carried out as follows:

[0033] Step 1, compressed powder: mix graphite powder, anti-wear agent, nickel powder, silver powder, lead oxide powder and phenolic resin at 80°C for 3 hours to obtain compressed powder;

[0034] Step 2, compression molding: pass the compressed powder obtained in step 1 through a 40-mesh sieve, and then place it in a 3t / cm 3 Pressed under pressure to a bulk density of 3.68g / cm 3 ~3.70g / cm 3 rough brushes;

[0035] Step 3. Roasting treatment: place the rough brush blank obtained in step 2 in a mesh belt furnace, and successively heat it under the conditions of 200°C, 260°C, 350°C, 450°C, 600°C, 700°C, and 780°C. After heating for 2.5 hours, a wind power generator brush is obtained.

Embodiment 2

[0036] Embodiment 2: In this embodiment, a wind power generation brush is prepared by mass parts from 40 parts of graphite powder, 59 parts of silver powder, 5 parts of lead oxide powder, 7 parts of nickel powder, 0.3 part of antiwear agent and 26 parts of phenolic resin wherein the graphite powder is flake graphite powder with an average particle diameter of 300 mesh, a carbon content ≥ 99%, and an ash content ≤ 1%; the antiwear agent is silicon carbide, and the average particle diameter of silicon carbide is 300 mesh. The particle size D50 of the silver powder was 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com