Raw material warping device for textile processing

A technology of raw materials and warp tubes, which is applied in the field of raw material warping devices for textile processing. It can solve the problems of not being able to adapt to different diameters of warp threads, warp thread winding, and cumbersome steps, so as to reduce the probability of breakage, avoid mutual entanglement, and expand adaptation. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

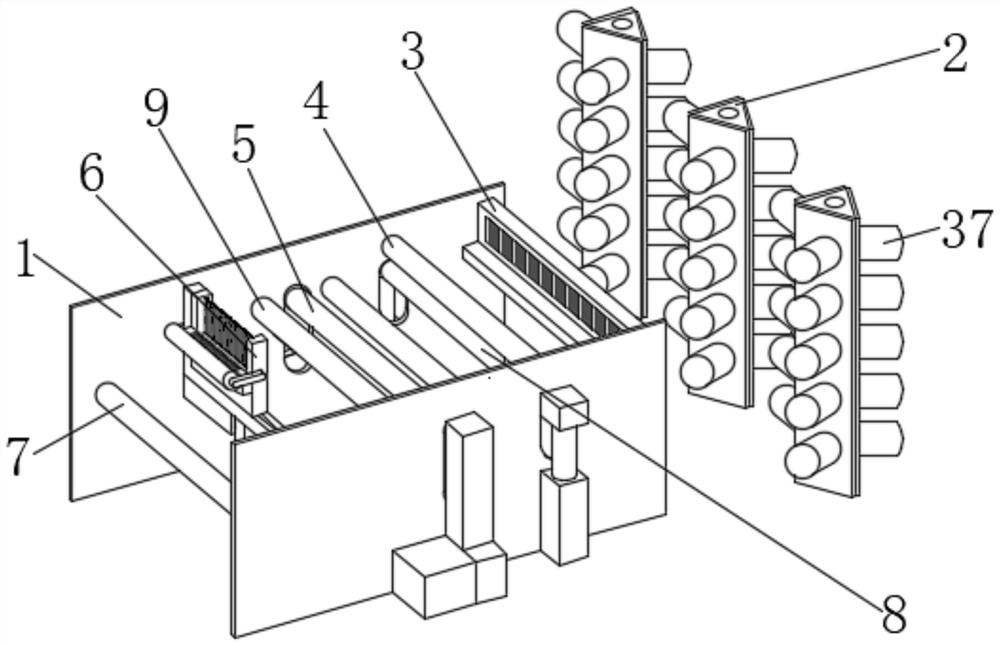

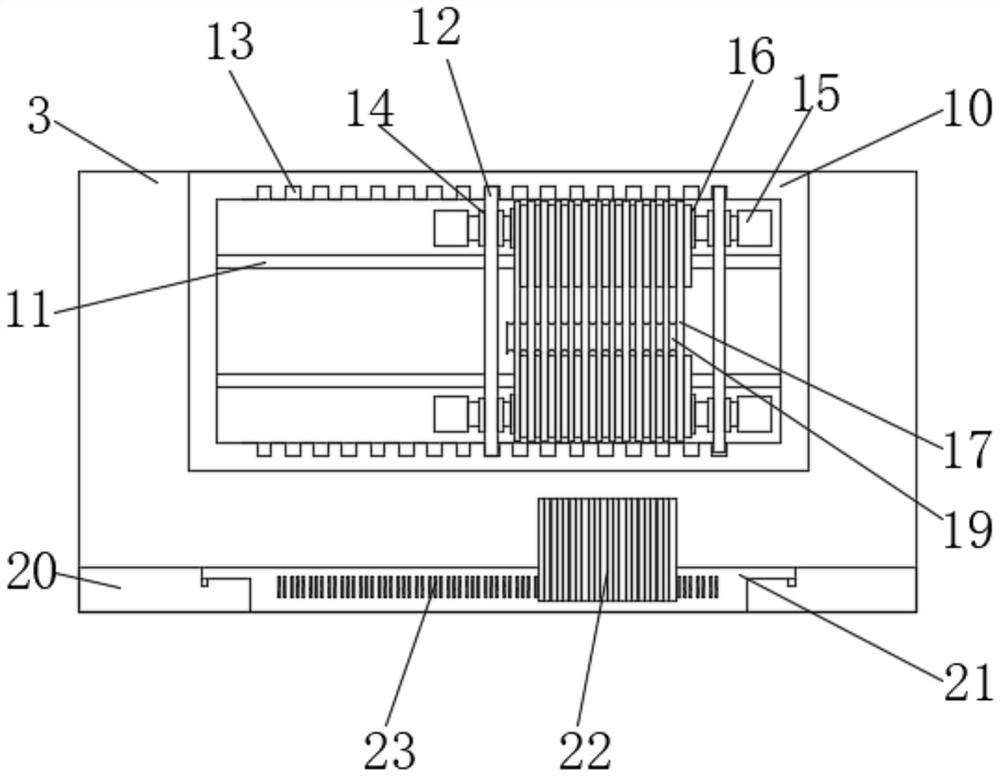

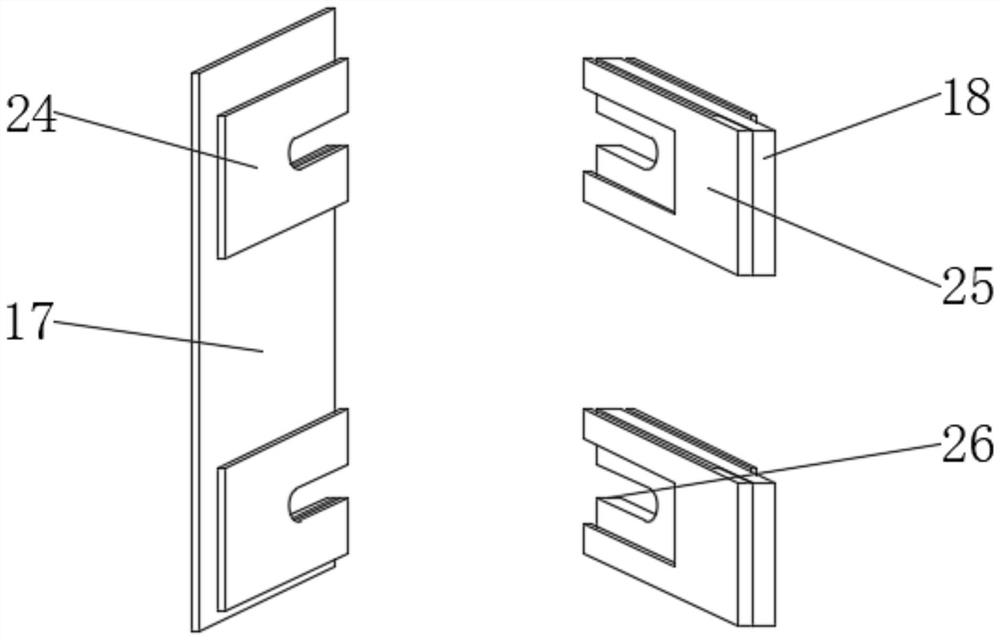

[0035] see Figure 1-8 Shown: a raw material warping device for textile processing, including a warping frame 1, one side of the warping frame 1 is provided with a number of warping cylinders 2 evenly distributed in an array, and a number of warping cylinders 2 are installed on the warping cylinder 2. The warp drums 37 are evenly distributed in an array. The inner side of the warping frame 1 is sequentially installed with the warping frame 3, the pressing roller 4, the tensioning roller 5, and the warp guide frame 6 from the side close to the warp cylinder 2 to the far side. And the warping roller 7, the warping device separates the war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com