Full-automatic shredded cake processing production line

A production line and dough technology, which is applied to dough processing, dough sheeting machine/rolling machine/rolling pin, baking, etc. It can solve the problems of single layering of the initial dough, no layering of the initial dough, and low taste , to achieve the effect of rich layering, reduced occupied area, and improved layering and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

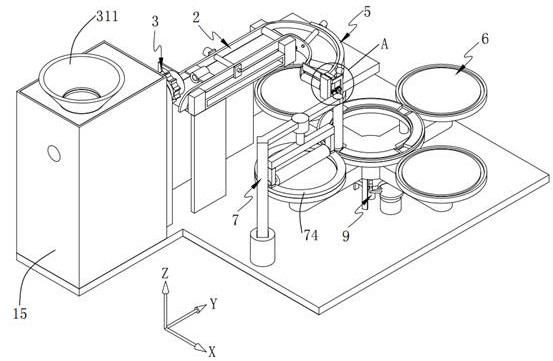

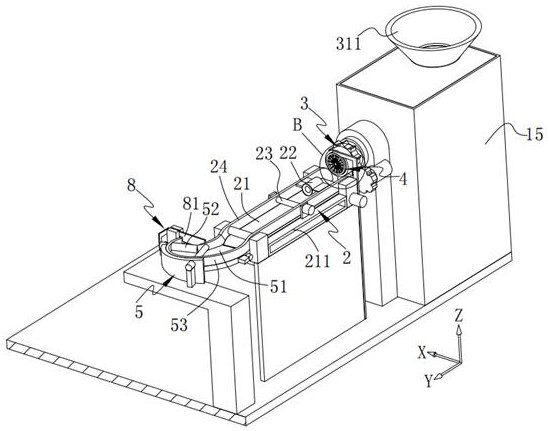

[0061] like Figure 1-8 As shown, the present invention provides a fully automatic hand-grabbing cake processing production line, including a rack 1;

[0062] Rolling conveying unit 2;

[0063] The rotary extrusion unit 3 is used for extruding the dough into a plurality of noodles and cooperating with the rolling conveying unit 2 to press and transport the plurality of noodles to rotate and twist the plurality of noodles into one. set on the rack 1;

[0064] An oiling unit 4, the oiling unit 4 for applying oil to the plurality of noodles before being twisted into a strand is arranged at the rotating extrusion unit 3;

[0065] The rolling conveying unit 2 for flattening and thinning the twisted noodles to form the initial dough is arranged in the extrusion direction of the rotating extrusion unit 3 .

[0066] When working, the seasonings in the dough are added by pre-mixing or spreading through the oiling unit 4; the rotary extruding unit 3 extrudes the dough into a pluralit...

Embodiment 2

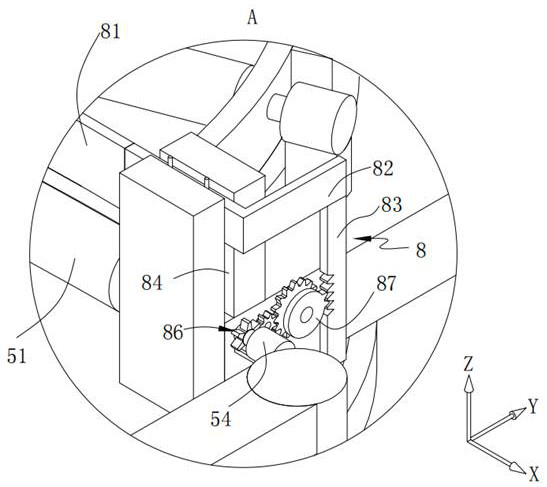

[0086] like Figure 1-8 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that a cutting unit 8 for intermittently cutting off the arc-shaped initial dough is provided at the output end of the arc-shaped conveying unit 5; The shape conveying unit 5 is driven by a common power member 54 .

[0087] Further, the cutting unit 8 includes a cutter 81, an L-shaped connecting plate 82, a rack 83, a guide groove 84, a second elastic member 85, a gear transmission assembly 86, an intermittent gear 87, a gear transmission assembly 86 and a second conveyance The driving of the belt 51 shares a power member 54 to realize that after the second conveyor belt 51 conveys the initial dough for a fixed length each time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com