Cooling type superfine dry powder extinguishing agent, preparation method and fire extinguishing equipment of cooling type superfine dry powder extinguishing agent

A fire extinguishing agent and powder technology, applied in fire protection equipment and other directions, can solve the problems of not giving full play to the cooling performance of water, hindering the application of E-type or lithium battery fires, etc., to improve safety, prevent fire re-ignition, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

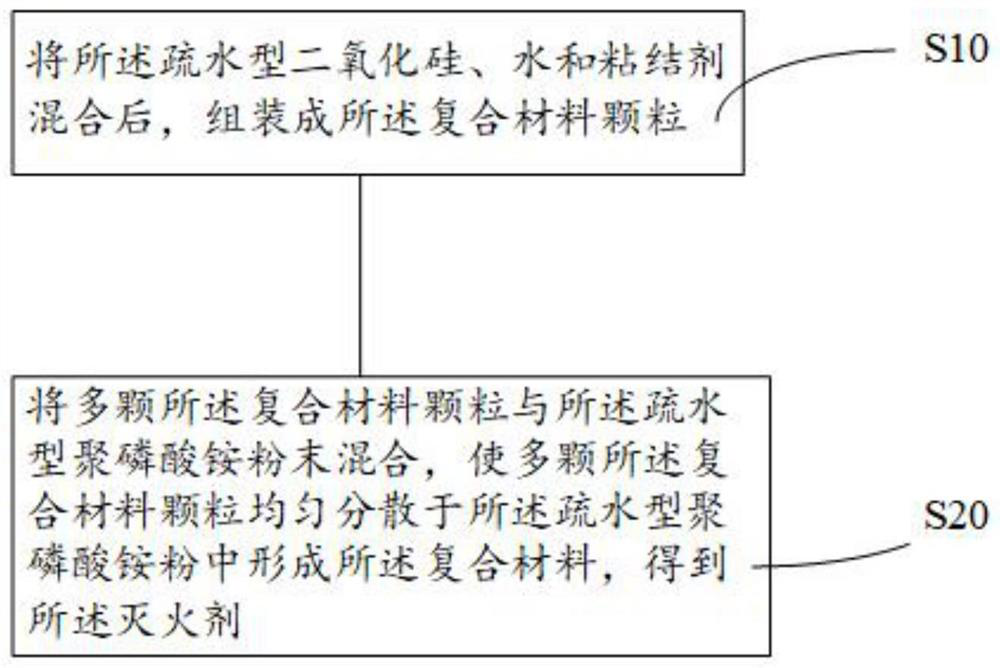

[0048] In addition, the present invention also provides a preparation method of the above fire extinguishing agent, such as figure 1 As shown, the preparation method of the fire extinguishing agent includes:

[0049] Step S10: after mixing the hydrophobic silica, water and a binder, assembling into the composite material particles;

[0050] Step S20 : mixing a plurality of the composite material particles with the hydrophobic ammonium polyphosphate powder, so that a plurality of the composite material particles are uniformly dispersed in the hydrophobic ammonium polyphosphate powder to form the composite material, and the obtained composite material is obtained. Extinguishing agent. By adopting the above steps, a fire extinguishing agent with good fire extinguishing effect can be prepared, the operation is simple, the production cost is low, and the fire extinguishing agent is suitable for mass production and popularization.

[0051] Step S10 includes:

[0052] Step S101:...

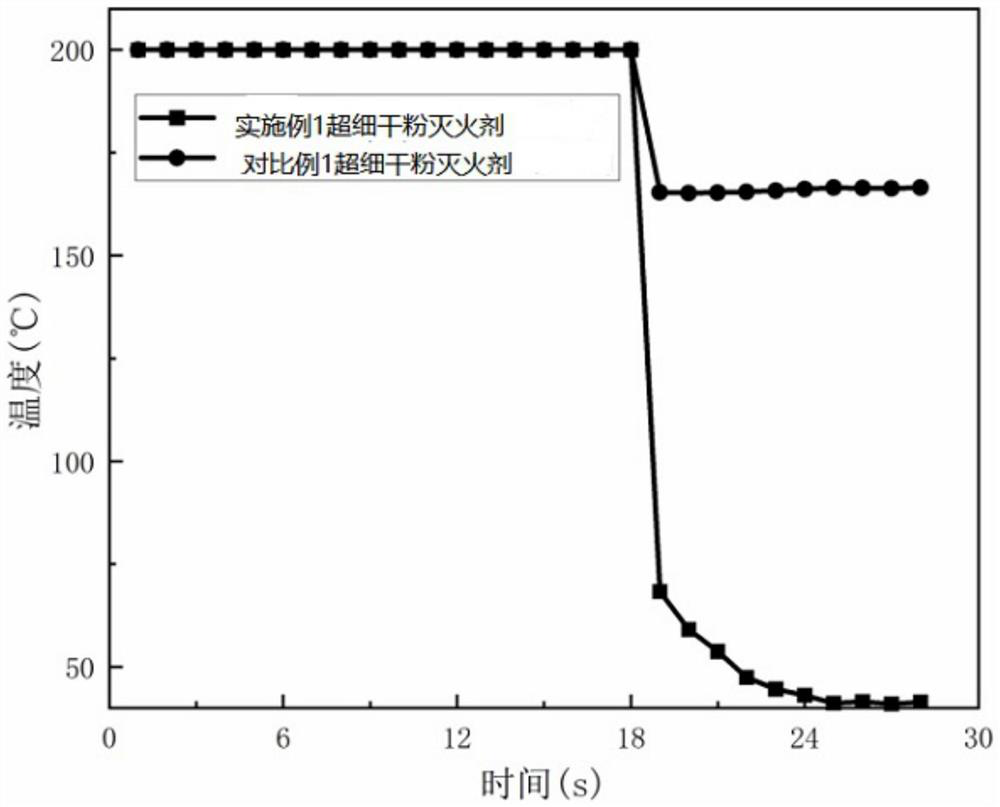

Embodiment 1~6

[0072] Embodiments 1 to 6 respectively provide a cooling type superfine dry powder fire extinguishing agent, the specific components are a composite material and a hydrophobic ammonium polyphosphate powder formed by a plurality of micron-sized hydrophobic ammonium polyphosphate particles, and the composite material is dispersed in A plurality of micron-sized composite material particles in the hydrophobic ammonium polyphosphate powder are composed together, each composite material particle includes an inner core layer and a coating layer, and the coating layer covers at least a part of the surface of at least the inner core layer, wherein the coating layer is composed of multiple layers. Hydrophobic nano-silica (purchased from Aladdin fumed silica CAS: 112945-52-5) is composed together, and the inner core layer includes gel water. In Examples 1 to 6, the parts by weight of the hydrophobic ammonium polyphosphate powder and the composite material are shown in Table 1.

[0073] T...

Embodiment 7~12

[0083] Embodiments 7 to 12 respectively provide a kind of fire extinguishing equipment, and its specific manufacturing method is as follows:

[0084] The fire extinguishing agent cooling type ultra-fine dry powder fire extinguishing agent prepared in Examples 1-6 was respectively filled into a general-purpose portable fire-extinguishing steel cylinder, and the cylinder was sealed after filling with nitrogen at 1.2 MPa to obtain fire-extinguishing equipment, wherein the fire-extinguishing equipment of Examples 7-12 The corresponding filling extinguishing agent cooling type ultra-fine dry powder extinguishing agent is shown in Table 3.

[0085] Table 3 Extinguishing agent cooling type ultra-fine dry powder fire extinguishing agent corresponding to the fire extinguishing equipment of Examples 7-12

[0086] fire fighting equipment Extinguishing agent cooling type ultra-fine dry powder fire extinguishing agent Example 7 Example 1 Example 8 Example 2 E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com