Preparation method and application of synthetic ammonia catalyst

A technology for synthesizing ammonia and catalysts, which is used in the preparation/separation of ammonia, chemical instruments and methods, catalysts for physical/chemical processes, etc. It can solve the problems of slow reaction of nitrogen and hydrogen, and achieve a small amount of catalyst, significant economic benefits, and high catalysis. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below through the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described herein are only used to explain the present invention, and not to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

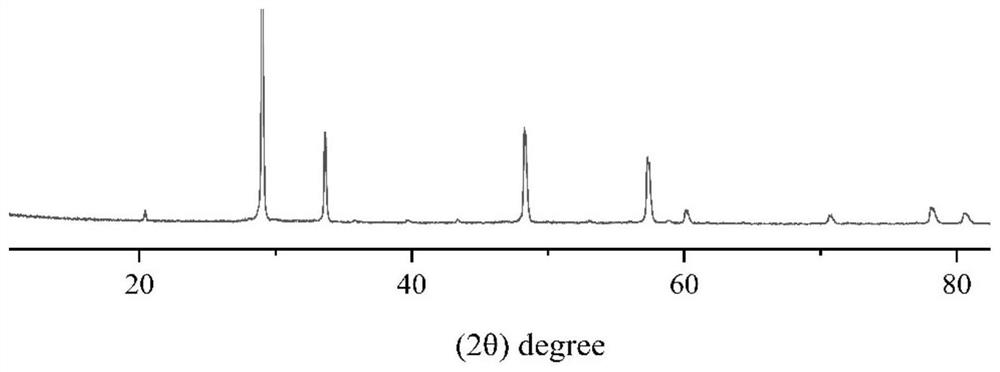

[0034] see Figure 1-Figure 3 , A kind of synthetic ammonia catalyst A kind of preparation method of synthetic ammonia catalyst, including MHO, wherein M=Al, Ga, Sc or Y, after described MHO introduces Ru ion and obtains Ru / MHO with catalytic activity through reduction, carries out the preparation of MHO first method, its preparation method is as follows:

[0035] (a)M 2 O 3 Pretreatment: Weigh 20-50g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com