Environment-friendly medium density fiberboard fiber preheating combined process and production equipment thereof

A kind of production equipment and MDF technology, which is applied in the field of environmental protection MDF fiber preheating combination process and its production equipment, can solve the problems of inconvenient slab, humidity error, multi-layer heating, etc., so as to improve the coating performance and reduce the preheating The effect of the cured layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

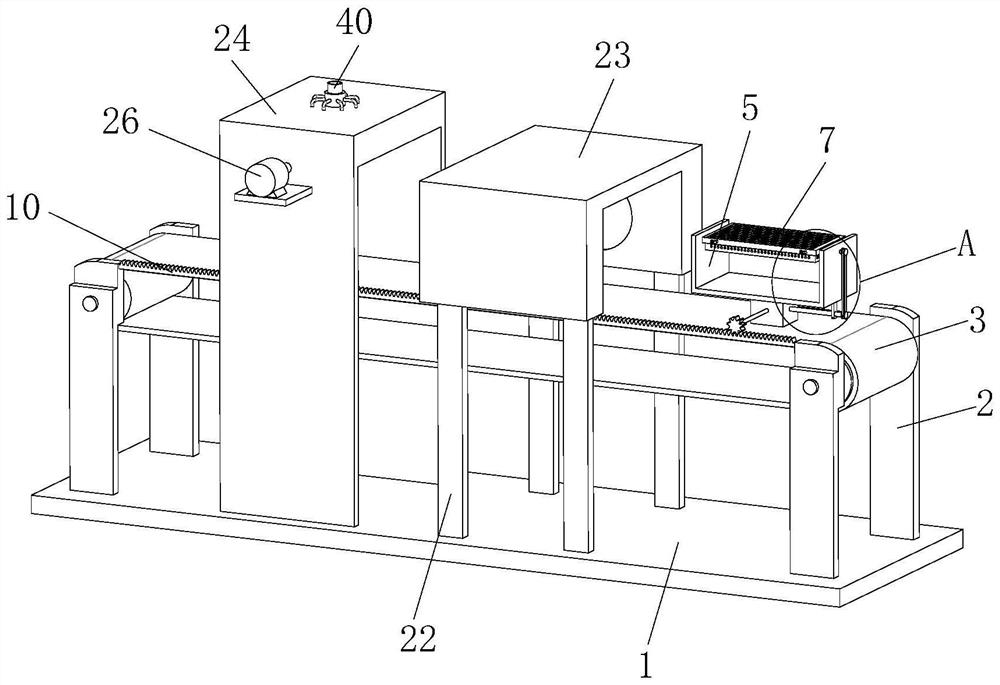

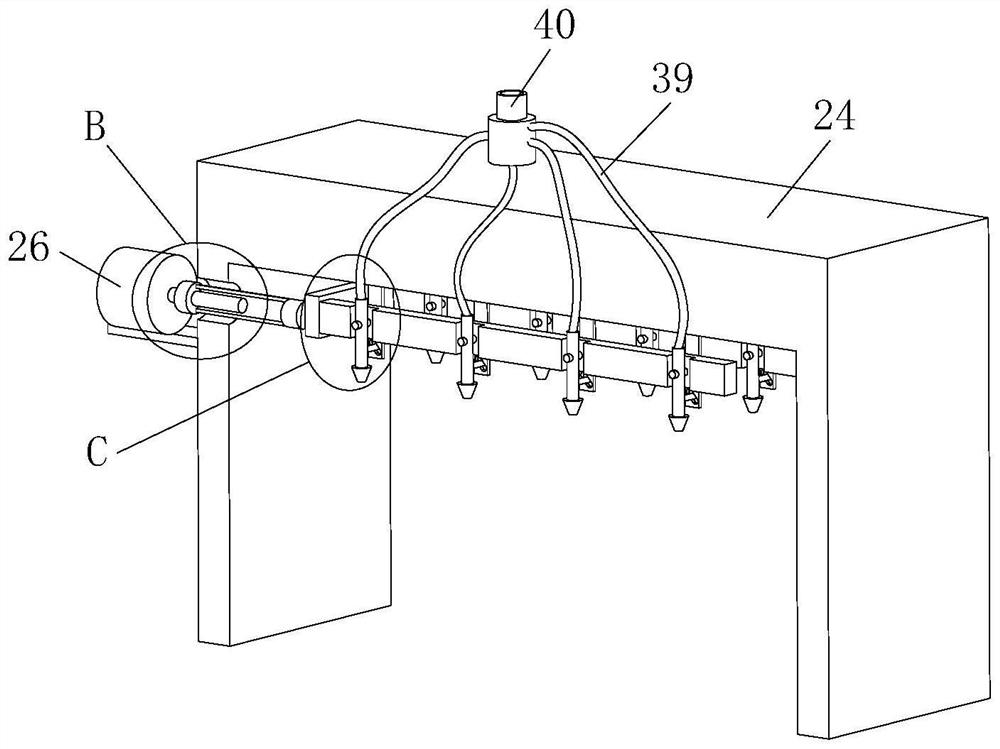

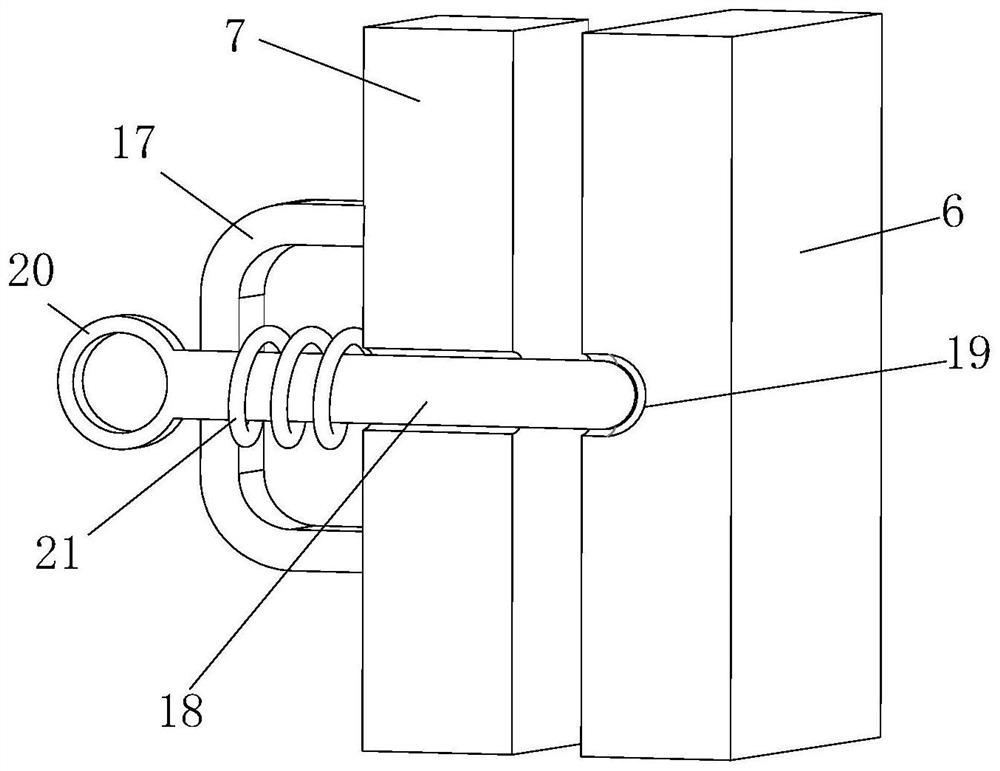

[0037] see Figure 1-7 , Environmental protection MDF fiber preheating combination process and its production equipment, including a bottom plate 1, the top of the bottom plate 1 is fixedly connected with two vertical plates 2 symmetrically in front and back, and a conveyor belt 3 is installed between the vertical plates 2, and the side walls of the conveyor belt 3 are fixed and connected. A number of shells 4 are fixedly connected, and the top surface of the shell 4 is fixedly connected with a fixed plate 5. The fixed plate 5 is arranged in a U shape. A leakage net 6 is arranged in the cavity of the fixed plate 5, and the top surface of the leakage net 6 is movably connected with a cover. Plate 7, the side wall of the fixing plate 5 is provided with a driving mechanism, the front and rear side walls of the cover plate 7 are respectively provided with two fixing mechanisms, the top surface of the bottom plate 1 is fixedly connected with four supporting plates 22, and the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com