Casting extrusion device for battery diaphragm production

A technology of cast extrusion and battery diaphragm, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of uneven cooling at both ends of the extrusion port and warping of the plate surface, so as to improve heating controllability, Effect of avoiding residual stress and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

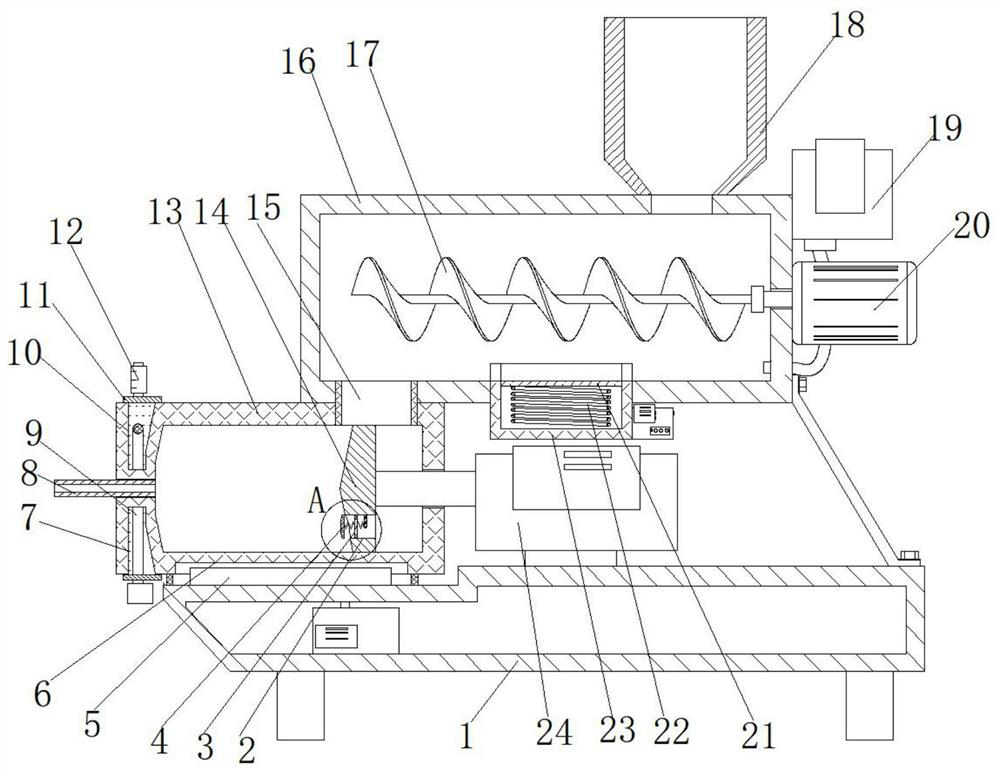

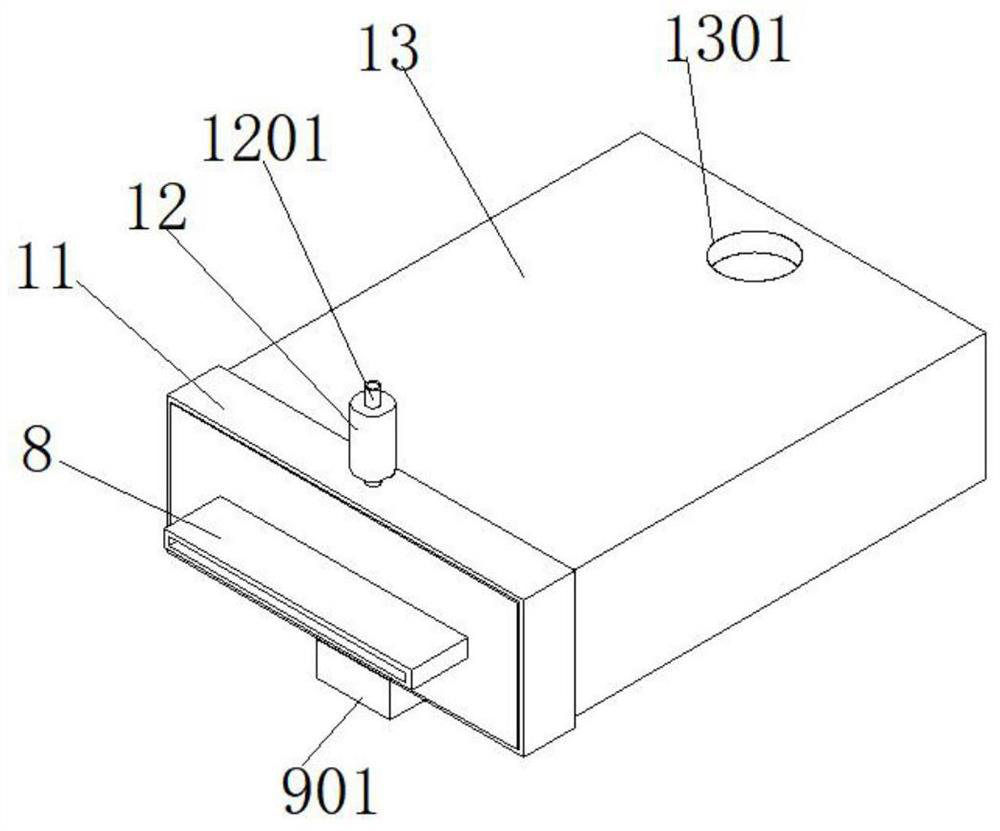

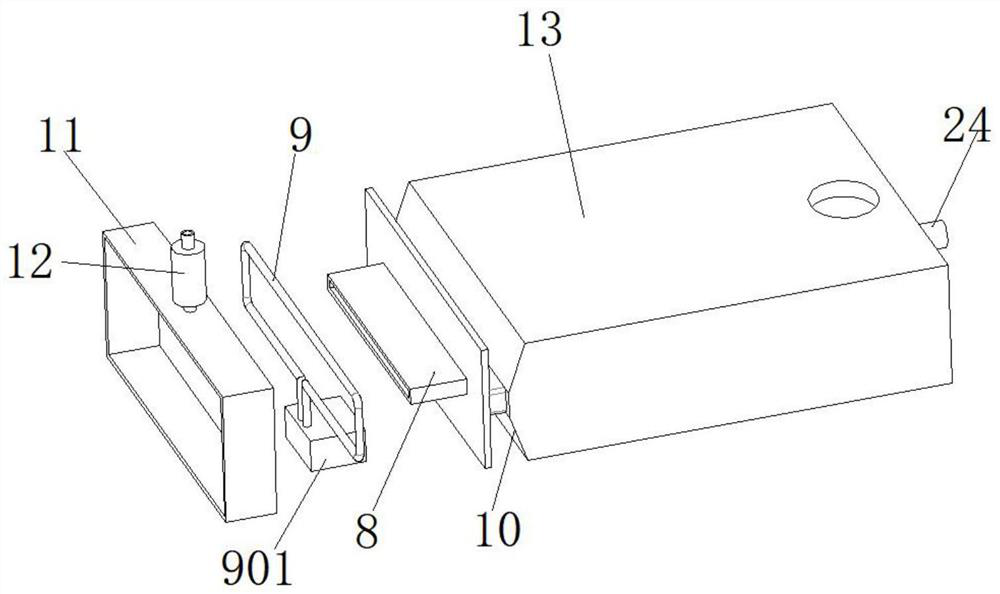

[0028] refer to Figure 1-5 , a casting extrusion device for battery diaphragm production, including a base 1 with a cavity inside, which is convenient for installing electrical components inside the base 1, the upper surface of the base 1 is set into a stepped structure, and the upper surface of the base 1 is relatively A support frame is fixed on the lower platform, the top of the support frame is fixed with an extrusion box 13 by bolts, and a hole is opened in the middle of one side of the extrusion box 13 close to the higher platform of the base 1, and the socket is slidably connected with a pusher. A pusher 24 is fixed on the upper surface of the base 1 close to the end of the pusher tube, and a pusher plate 14 is fixed at one end of the pusher tube away from the pusher device 24, and a rectangular hole is opened in the middle of one end of the extrusion box 13 away from the pusher device 24, And a discharge pipe 8 is inserted into the rectangular hole, the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com