Double-sided printing material collecting and discharging structure capable of discharging materials and collecting materials upwards

A technology of double-sided printing and feeding and unwinding, which is applied to printing devices, printing, etc., and can solve problems such as easy ink staining and low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

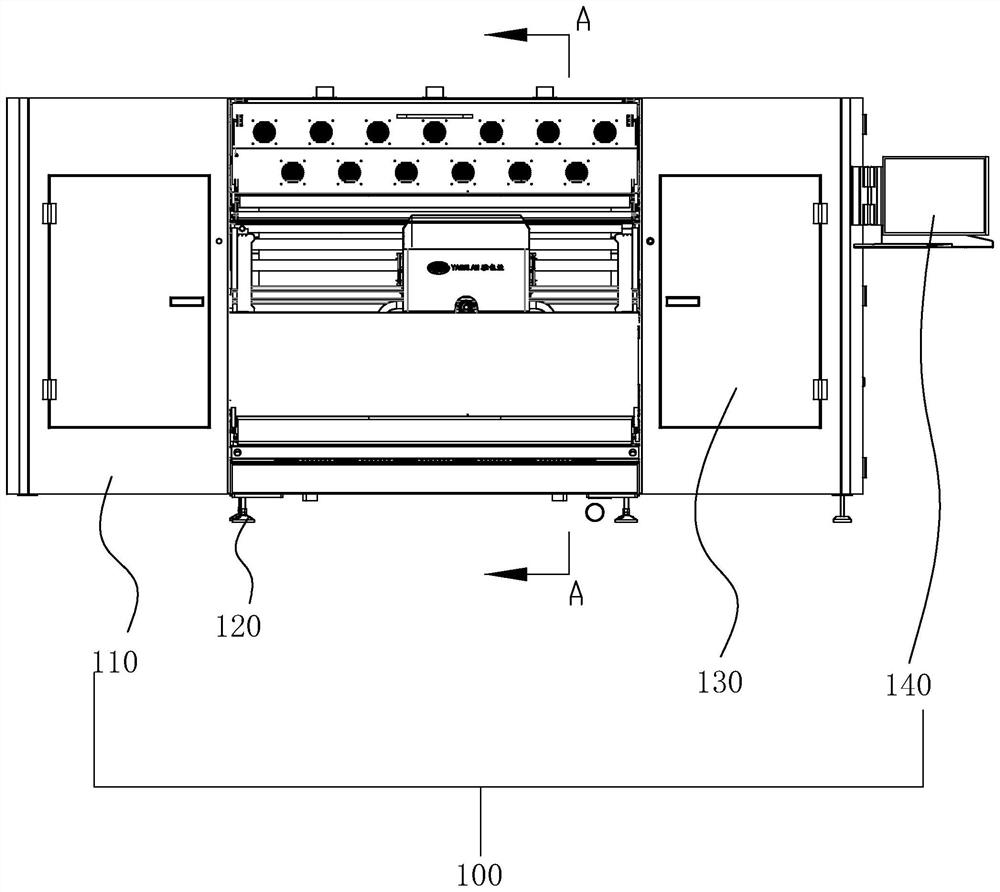

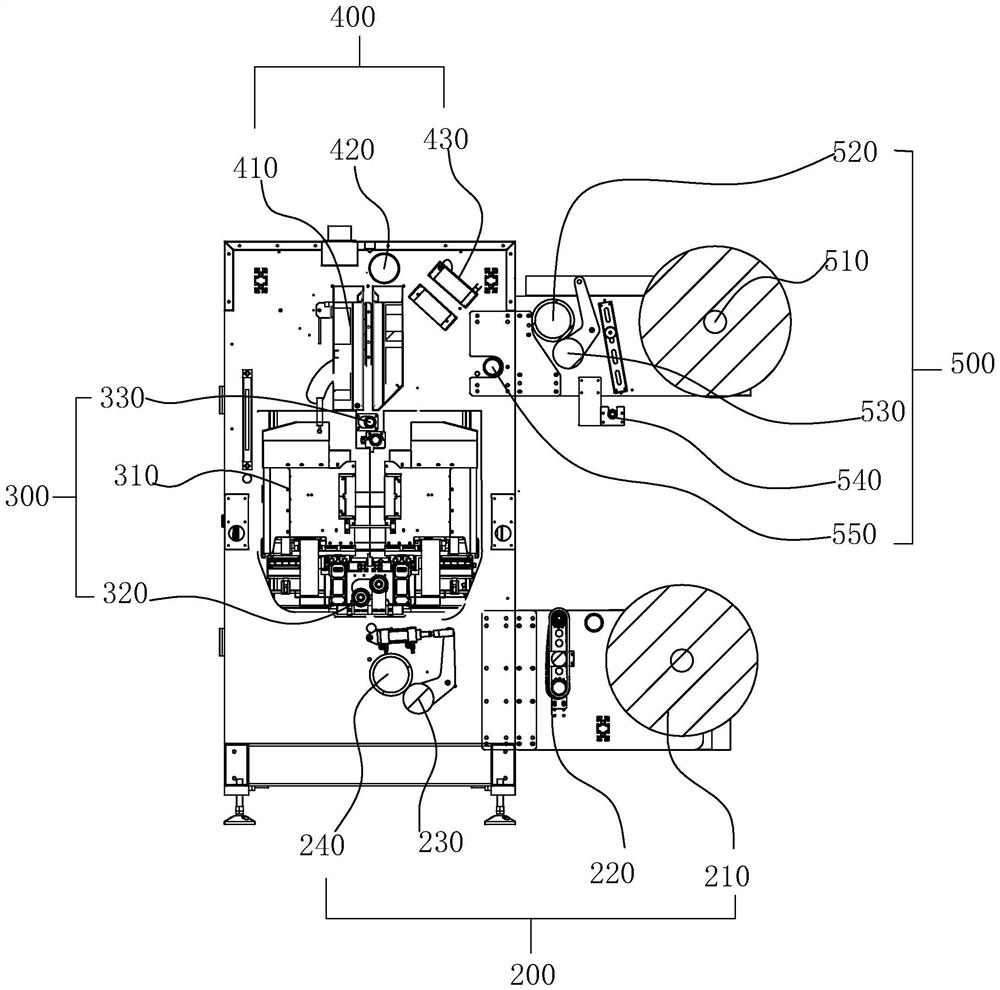

[0047] Example 1, see figure 1 and figure 2 , the upper and lower double-sided printing receiving and unwinding structure, including the rack 100 , the feeding assembly 200 , the printing assembly 300 , the drying assembly 400 and the receiving assembly 500 .

[0048] The rack 100, a receiving assembly 500 is disposed on the top of one side of the rack 100, a feeding assembly 200 is disposed at the bottom of one side of the rack 100, and a printing assembly 300 is disposed in the middle of the inner cavity of the rack 100 , the top of the inner cavity of the rack 100 is provided with a drying assembly 400 .

[0049] Specifically, the rack 100 includes a frame 110, the bottom four corners of the frame 110 are provided with support legs 120, the front surface of the frame 110 is provided with access doors 130 on both sides, and the right side of the frame is provided with a man-machine Operation panel 140 .

[0050] Specifically, the feeding assembly 200 includes a feeding r...

Embodiment 2

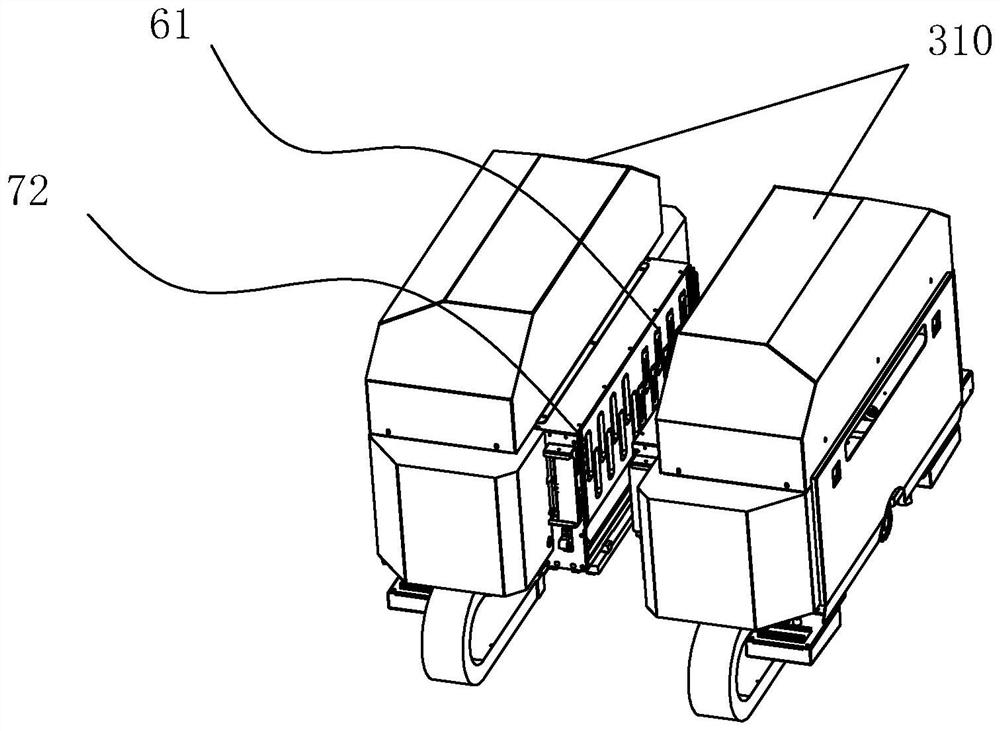

[0065] Embodiment 2, the upper and lower double-sided printing and unwinding material structure is placed down, and the difference between it and Embodiment 1 is as follows: Figure 6-Figure 8 The top of a guide roller 420 is provided with a smoke exhaust mechanism 91 for inhalation, the air suction port of the smoke exhaust mechanism 91 is arranged obliquely downward, and the lower end of the smoke exhaust mechanism 91 is connected with an oil collecting groove 92; the smoke exhaust mechanism 91 as a whole is an oil absorption The purpose of the hood is to absorb the flue gas and vaporized ink during the printing process of the equipment, keep the inside of the equipment clean, and prevent the internal components of the equipment from being polluted by the vaporized ink.

[0066] A guide roller 420 is in contact with the driven sponge roller 93. Since a guide roller 420 will first contact the ink dried by infrared, a guide roller 420 will adhere to a small amount of undried in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com