Energy-saving self-circulation A3O-MBBR sewage treatment device and method thereof

A sewage treatment device and self-circulation technology, applied in biological treatment devices, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of complex management, large equipment and facilities, and high energy consumption in operation. Achieve the effects of low energy consumption, short construction period and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

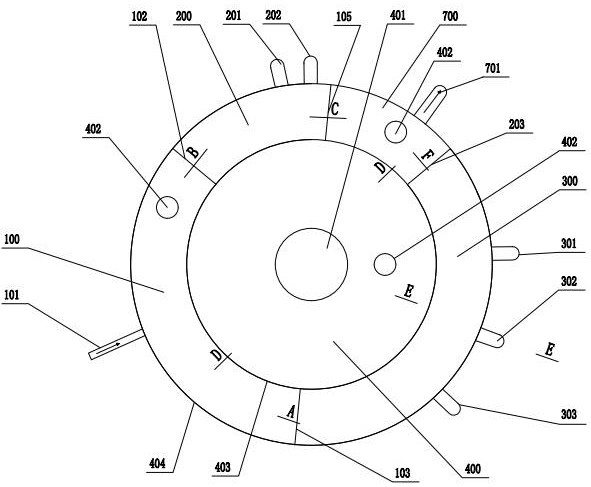

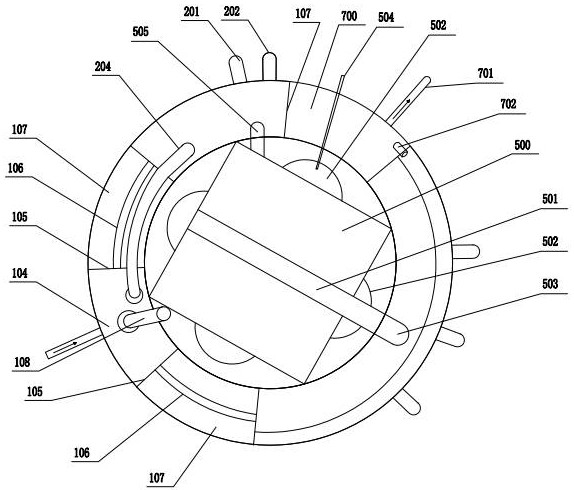

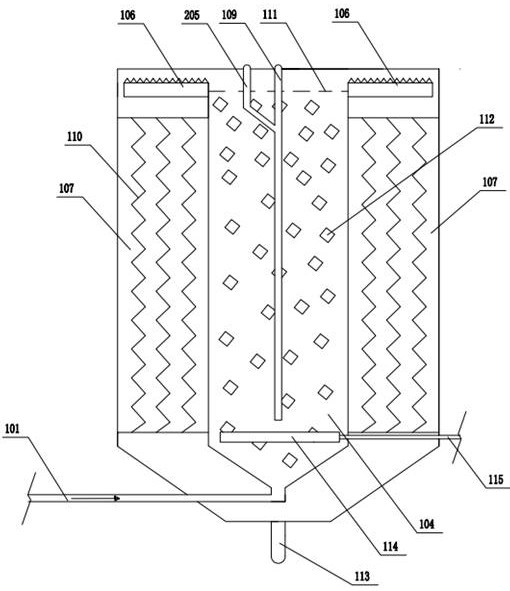

[0036] refer to Figure 1-8, an energy-saving self-circulating A3O-MBBR sewage treatment device, including an inner circular plate 403, an outer circular plate 404, the inner circular plate 403 and the outer circular plate 404 are concentric circular ring plates, and the outer circular plate 404 is sleeved outside the inner circular plate 403 The sewage treatment device is composed. An annular gap chamber is formed between the inner circular plate 403 and the outer circular plate 404. The annular gap chamber is provided with a separator 102, a separator 2 103, a separator 105, and a separator 4 203. The anaerobic reaction zone 100 is set b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com