Spraying type heat exchange sewage circulation flash steam generation system

A technology for generating system and flash steam, which is applied in the fields of sewage treatment, heavy oil thermal recovery, waste heat utilization, and seawater desalination. Achieve the effect of increasing the flash evaporation rate and realizing the cascade utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

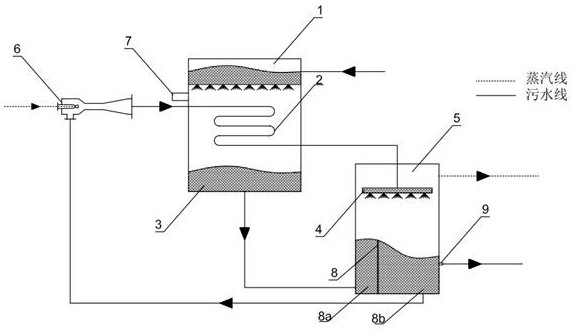

[0012] The technical solutions in the implementation of the present invention will be clearly and completely described below with reference to the accompanying drawings of the present invention.

[0013] figure 1 Shown is a device diagram of a shower-excited heat-exchange sewage circulating flash steam generation system.

[0014] The steam generation system proposed by the present invention includes a water distribution tank 1, a shower-excited heat exchanger 2, a catchment tank 3, a sprayer 4, a flash tank 5 and a vapor-liquid ejector 6, and pipes are used to connect each device; The upper part of the exciter heat exchanger 2 is provided with a volatile gas discharge port 7, and the flash tank 5 is provided with a water baffle 8 and an overflow pipe 9; the steam generation system is driven by high-pressure steam to a vapor-liquid ejector 6, and the flash tank is sucked The non-flash saturated sewage gathered in 5 is heated and pressurized and sent to the shower type heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com