Nano-enzyme with multistage enzyme-linked reaction performance as well as preparation method and application of nano-enzyme

An enzyme-linked reaction and nano-enzyme technology, which is applied in the direction of botany equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of high production cost and poor stability, and achieve low toxicity, good biocompatibility, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1, block g-C 3 N 4 Preparation: put 6g of dicyandiamide into a ceramic calcining boat, heat up from 20°C to 550°C at a constant rate within 4 hours in an air atmosphere, and keep it in an air atmosphere for 4 hours; after the insulation, it is naturally cooled to room temperature and ground to obtain Block g-C 3 N 4 ;

[0043] Step 2, g-C 3 N 4 Preparation of nanosheets: 3 g bulk g-C 3 N 4 Disperse in 30mL anhydrous H 2 SO 4 Stir for 1 hour in medium to obtain g-C 3 N 4 / H 2 SO 4 mixture; gradually add 10 mL of deionized water to g-C 3 N 4 / H 2 SO 4 In the mixture, a clear solution was obtained. The clear solution was then added to 90 mL of absolute ethanol and stirred for 18 hours, and dialyzed to neutrality in deionized water with a dialysis bag (membrane cutoff: 3500 kDa) (to remove residual SO). 4 2- and ethanol), collected after drying at 60 °C to obtain g-C 3 N 4 Nanosheets (g-C 3 N 4 NS);

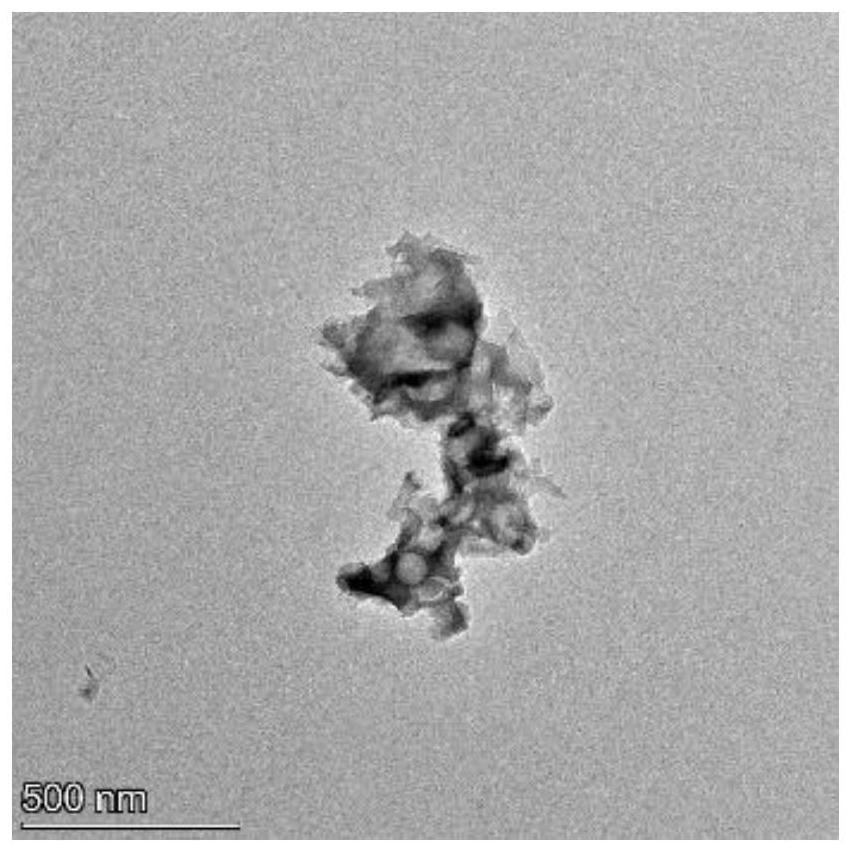

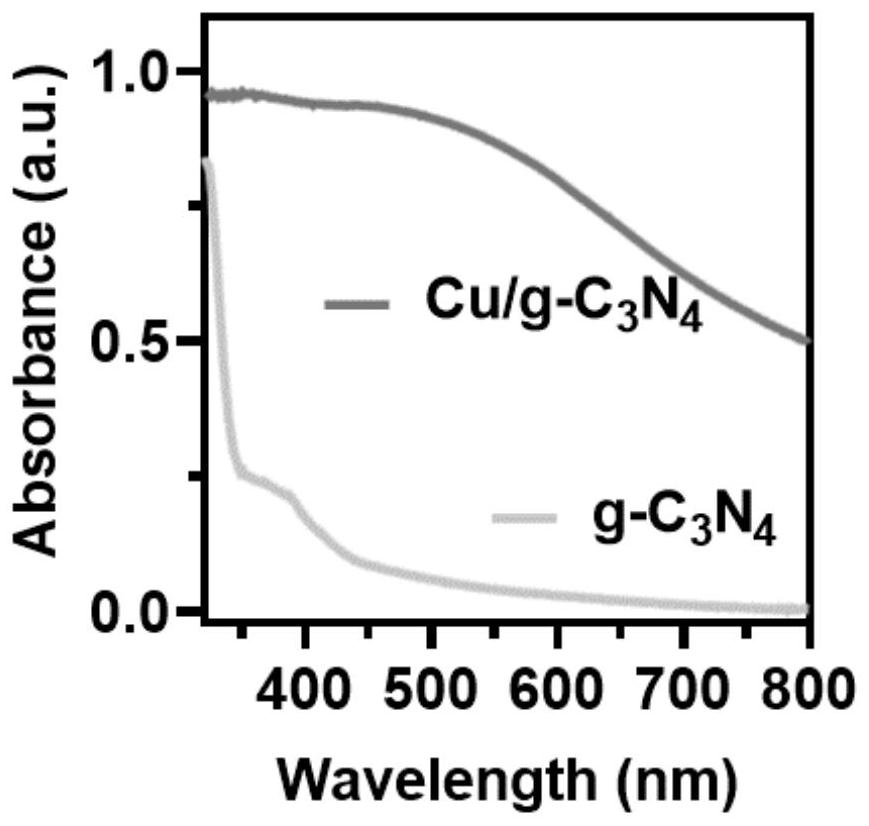

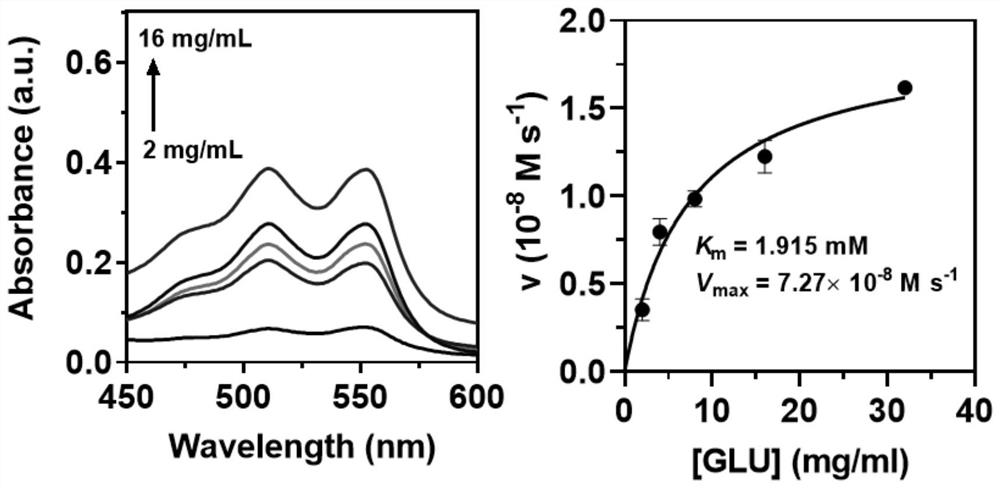

[0044] Step 3, Nanozyme (Cu / g-C 3 N 4 ) p...

Embodiment 2

[0054] Step 1, block g-C 3 N 4 Preparation: put 6g of dicyandiamide into a ceramic calcining boat, heat up from 20°C to 500°C at a constant rate within 3 hours in an air atmosphere, and keep it in an air atmosphere for 5 hours; after the insulation, it is naturally cooled to room temperature and ground to obtain Block g-C 3 N 4 ;

[0055] Step 2, g-C 3 N 4 Preparation of nanosheets: 3 g bulk g-C 3 N 4 Disperse in 30mL anhydrous H 2 SO 4 Stir for 1 hour in medium to obtain g-C 3 N 4 / H 2 SO 4 mixture; gradually add 10 mL of deionized water to g-C 3 N 4 / H 2 SO 4 In the mixture, a clear solution was obtained. The clear solution was then added to 120 mL of absolute ethanol and stirred for 16 hours, and dialyzed to neutrality (to remove residual SO) in deionized water with a dialysis bag (membrane cutoff: 3500 kDa). 4 2- and ethanol), dried at 50 °C and collected to obtain g-C 3 N 4 Nanosheets (g-C 3 N 4 NS);

[0056] Step 3, Nanozyme (Cu / g-C 3 N 4 ) pre...

Embodiment 3

[0059] Step 1, block g-C 3 N 4 Preparation: put 6g of dicyandiamide into a ceramic calcining boat, heat up from 20°C to 600°C at a constant rate within 5 hours in an air atmosphere, and keep it in an air atmosphere for 3 hours; after the insulation, it is naturally cooled to room temperature and ground to obtain Block g-C 3 N 4 ;

[0060] Step 2, g-C 3 N 4 Preparation of nanosheets: 3 g bulk g-C 3 N 4 Disperse in 30mL anhydrous H 2 SO 4 Stir for 1 hour in medium to obtain g-C 3 N 4 / H 2 SO 4 mixture; gradually add 10 mL of deionized water to g-C 3 N 4 / H 2 SO 4 In the mixture, a clear solution was obtained. The clear solution was then added to 105 mL of absolute ethanol and stirred for 20 hours, and dialyzed to neutrality (to remove residual SO) in deionized water with a dialysis bag (membrane cutoff: 3500 kDa). 4 2- and ethanol), collected after drying at 55 °C to obtain g-C 3 N 4 Nanosheets (g-C 3 N 4 NS);

[0061] Step 3, Nanozyme (Cu / g-C 3 N 4 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com