High-temperature-resistant all-metal ball type piston downhole drilling tool

An all-metal, high-temperature-resistant technology, which is applied in drill pipes, drill pipes, earthwork drilling, etc., can solve problems such as high-temperature failure efficiency, and achieve the effects of small energy loss, reduced kinetic energy loss, and fast torque increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

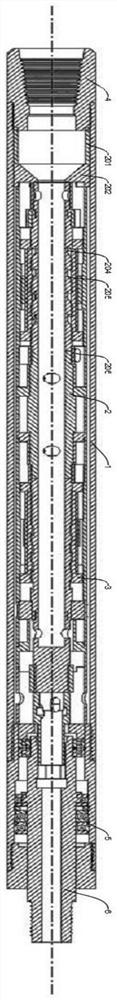

[0031] Attached to the following Figure 1-8 This application will be described in further detail.

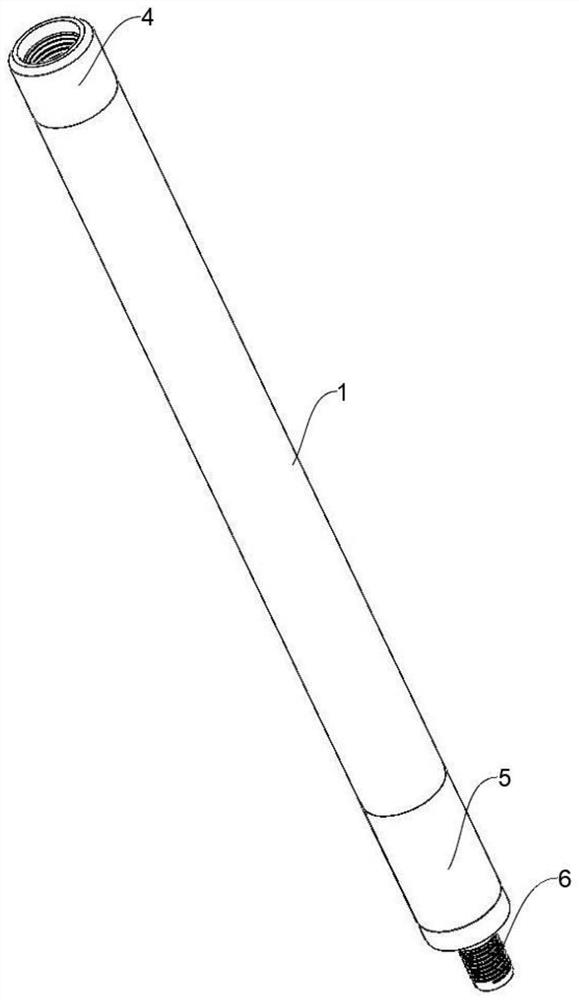

[0032] The implementation of the present application discloses a high temperature resistant all-metal ball-type piston downhole drilling tool. refer to figure 1 , the all-metal ball piston downhole drilling tool includes an outer pipe 1, a joint 4, a bearing section 5 and a main shaft 6, the joint 4 is threadedly connected to one end of the outer pipe 1, the bearing section 5 is threadedly connected to the other end of the outer pipe 1, and the main shaft 6 It is connected with the other end of the bearing segment 5 to form the whole drilling tool.

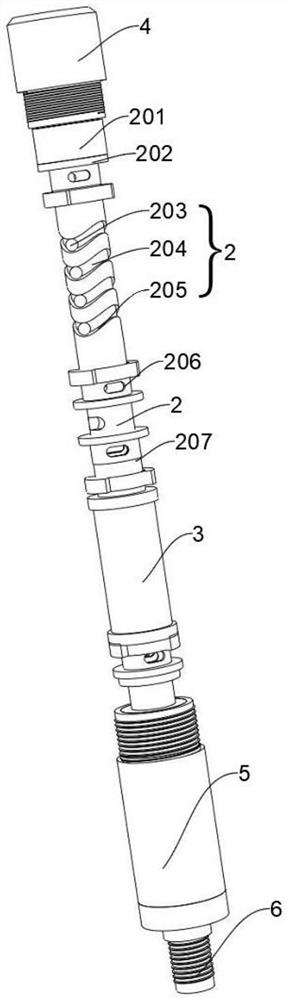

[0033] refer to figure 2 and image 3 , the outer tube is equipped with: 2 rotors; 201, retaining ring; 202, distribution valve; 203, ball; 204, spiral groove low; 205, spiral groove curve edge; 206, rotor inlet and outlet; , the hexagonal output shaft of the rotor; in this embodiment, the distribution mechanism 202 and the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap