All-fiber towed hydrophone array, manufacturing method and hydrophone method

An all-fiber and hydrophone technology, which is applied in the direction of cladding optical fiber, grating fiber, multi-core optical fiber, etc., can solve the problem of difficult to achieve high-precision array self-correction, so as to avoid underwater electromagnetic pulse interference and improve the application performance and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

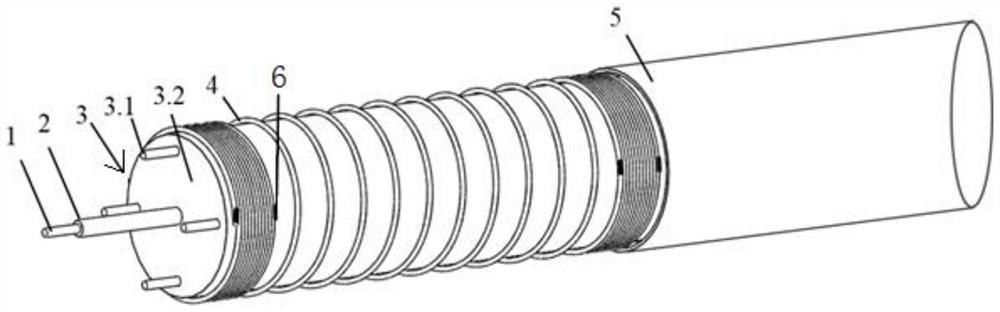

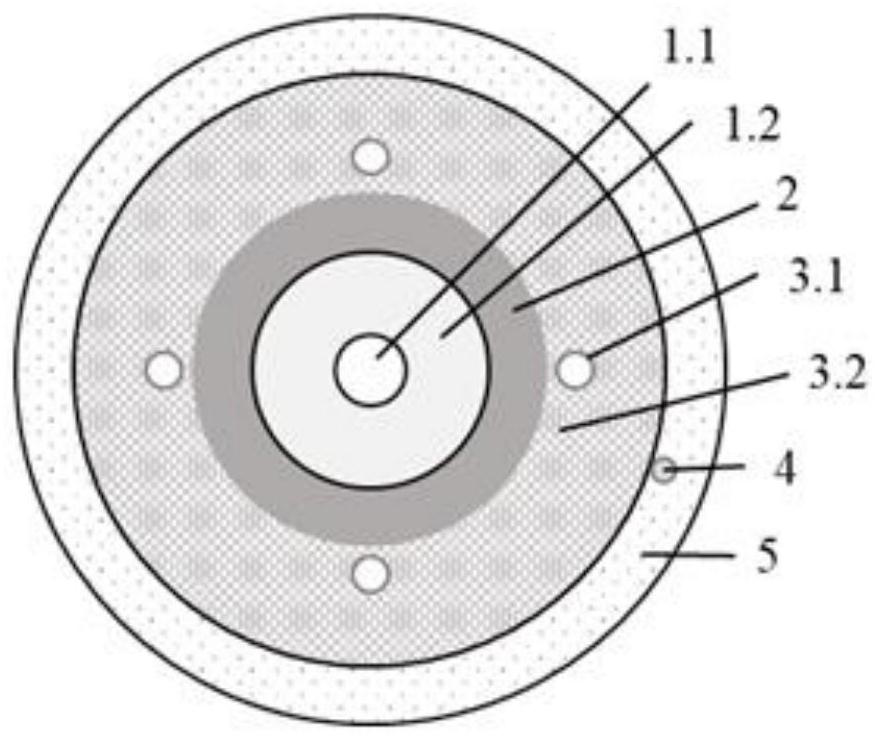

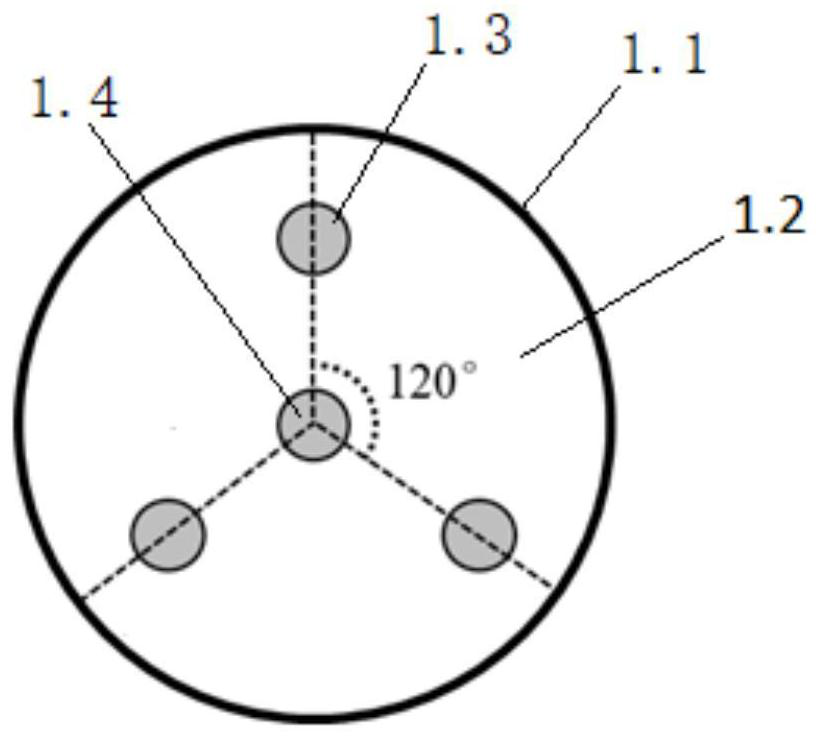

[0028] like Figures 1 to 4 The shown all-fiber towed hydrophone array includes an all-fiber attitude sensor 1, a hollow tube 2, a hollow mandrel 3 and a tight-packed grating array fiber 4. The all-fiber attitude sensor 1 (1 mm in diameter) consists of four The core grating array fiber 1.1 and the protective layer 1.2 covering the four-core grating array fiber 1.1 are composed. , the tight-packed grating array fiber 4 adopts the alternately dense and sparse winding method, and is wound on the hollow mandrel 3 with a constant tension, and the winding tension is maintained at 50-200g, which can be adjusted to improve the coupling between the tight-packed grating array fiber and the mandrel. Efficiency, to avoid slack in the tight-packed grating array fiber winding, which affects the measurement of sound pressure signals. Two adjacent g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com