Semiconductor power device reliability detection box and detection method

A technology for power devices and detection methods, which is applied in the fields of instruments, electrical measurement, short-circuit testing, etc., can solve the problems of lack of theory, detection methods, and methods of impurity ion evaluation, and achieve simple experimental methods and on-site practicality. Good, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In view of the above technical solutions, preferred embodiments are now given and described in detail with reference to the drawings.

[0033] The semiconductor power device 100 of the present invention is: the drain-source reverse biasing and gate-source reverse biasing of various power MOSFETs; the collector-emitter or emitter-base reverse biasing of various bipolar transistors; The gate of the junction FET is sophisticated in reverse bias; the diode is reverse biased.

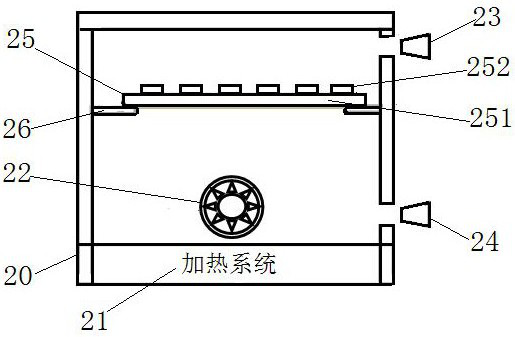

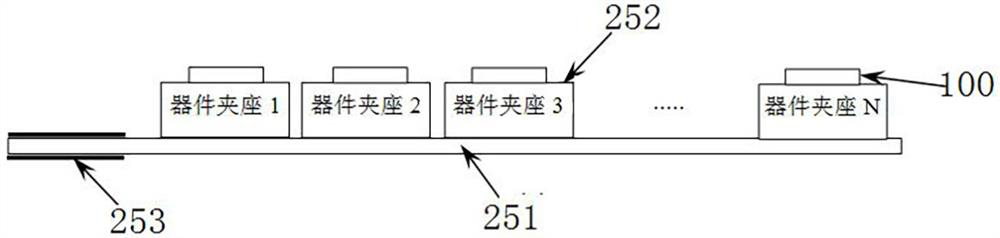

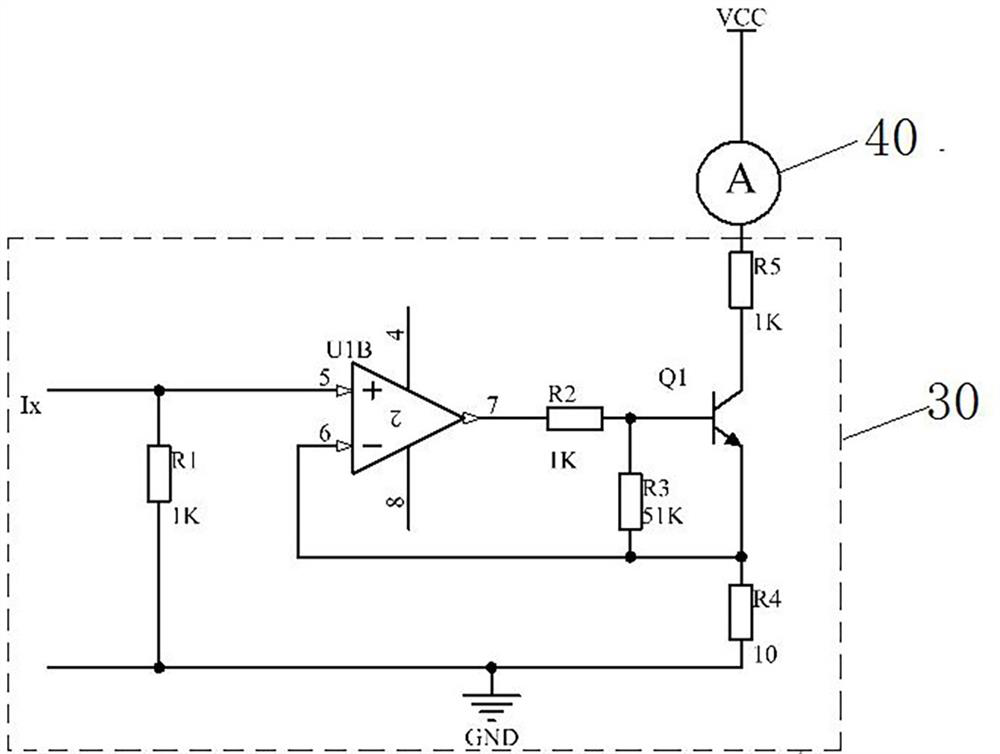

[0034] The reliability test box can be obtained commercially. Its general structure is, see figure 1 , including an openable and closable box 20 with a door, and a heating system 21 is arranged at the bottom of the box 20 to heat the box, see the circuit diagram of the heating system Figure 4 , adjust the temperature inside the box. The heating system 21 also includes a heat soaking fan 22 arranged in the box body to make the temperature inside the box body uniform. A block 23 for the hot air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com