Double-cavity structure capable of effectively reducing blind area of ultrasonic sensor and packaging process of double-cavity structure

An ultrasonic and sensor technology, which is applied in the field of double-cavity structure and its packaging technology, can solve the problems of poor assembly consistency, low production efficiency, and high production cost, and achieve high processing consistency, enhanced emission sound pressure level, structure and packaging technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

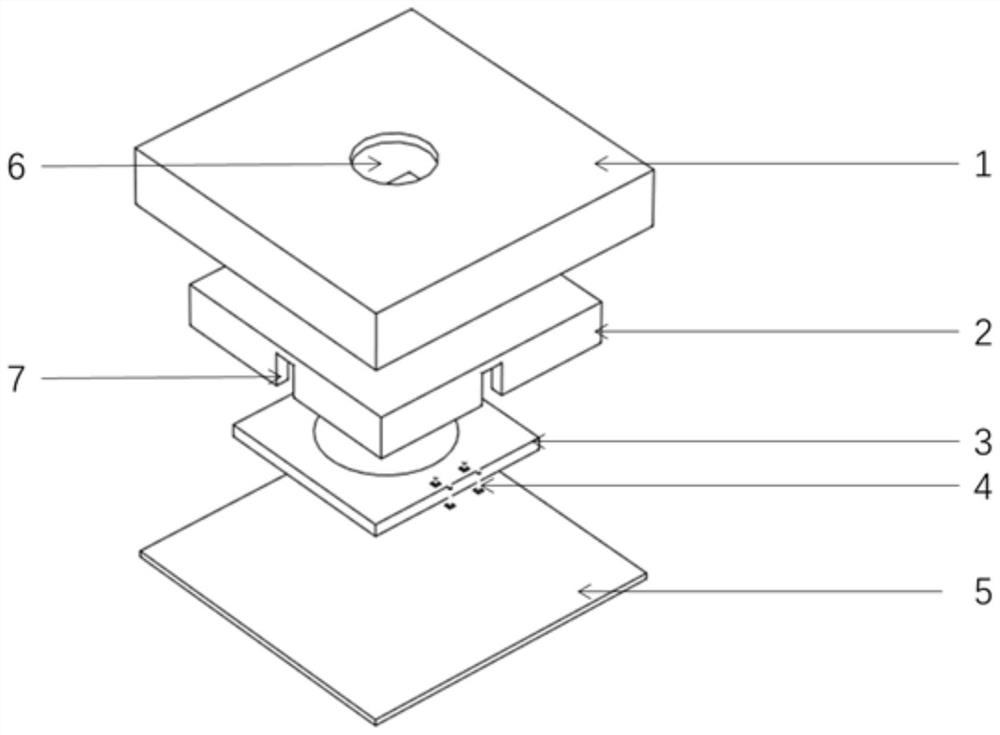

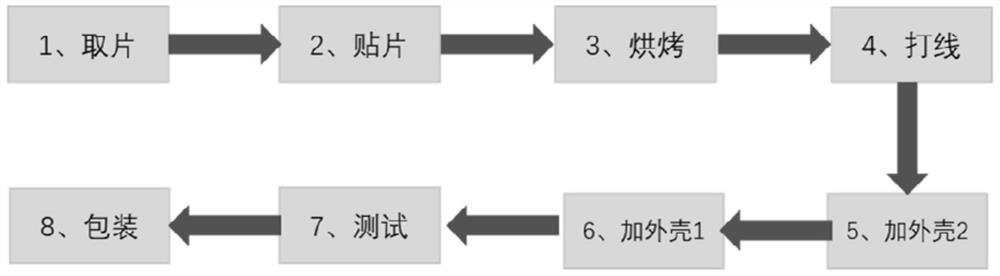

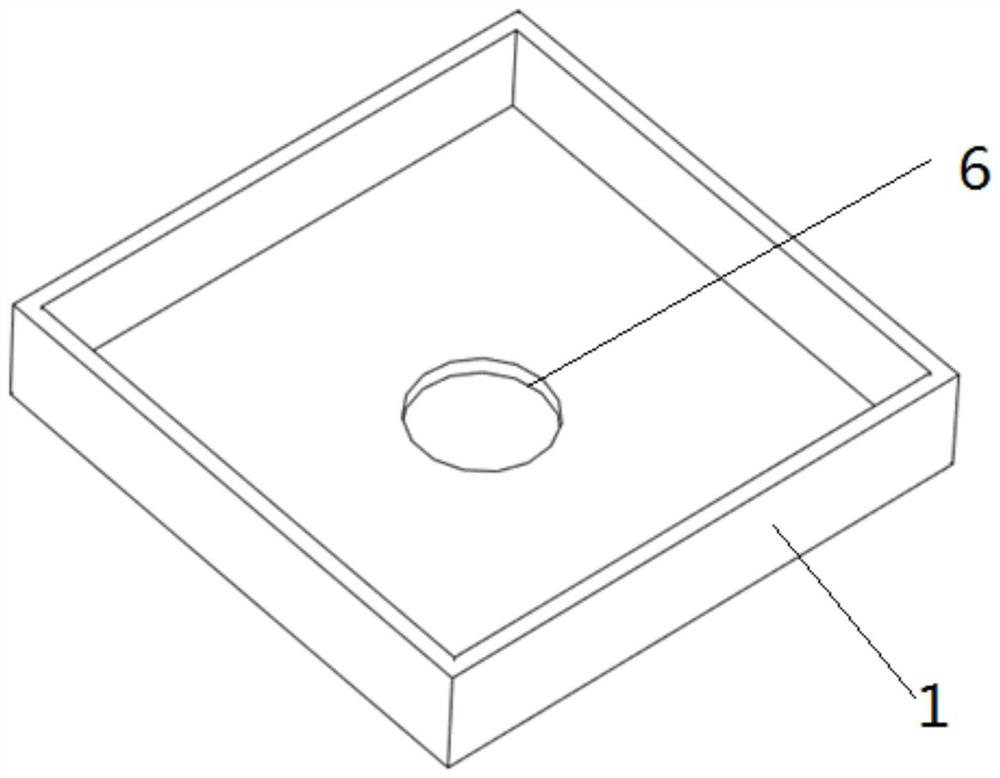

[0076] A dual-cavity structure that effectively reduces the blind area of an ultrasonic sensor includes an outer package shell, an inner package shell, a chip, and a substrate, the outer package shell is adhered to the edge of the substrate and enclosed with the substrate to form a first cavity, the The chip is bonded and arranged on the substrate, the chip is electrically connected to the substrate through bonding wires, the inner package shell is bonded and arranged on the substrate, and the bottom edge of the inner package shell is located between the bottom edge of the outer package shell and the edge of the chip In between, the inner package shell and the substrate are enclosed to form a second cavity, the top of the outer package shell is provided with a circular sound outlet, and the side walls of the inner package shell are provided with square sound holes .

Embodiment 2

[0078] On the basis of Embodiment 1, a waterproof and dustproof film is also provided on the external packaging shell.

Embodiment 3

[0080] On the basis of the above embodiment, the chip is a piezoelectric ultrasonic chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com