Rapid lace noodle pressing forming machine

A molding machine and fast technology, applied in dough molding machinery or equipment, dough extruder, dough processing and other directions, can solve the problems of food safety hazards, slow noodle lace pressing, low production efficiency, etc. The effect of preventing dough sticking and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

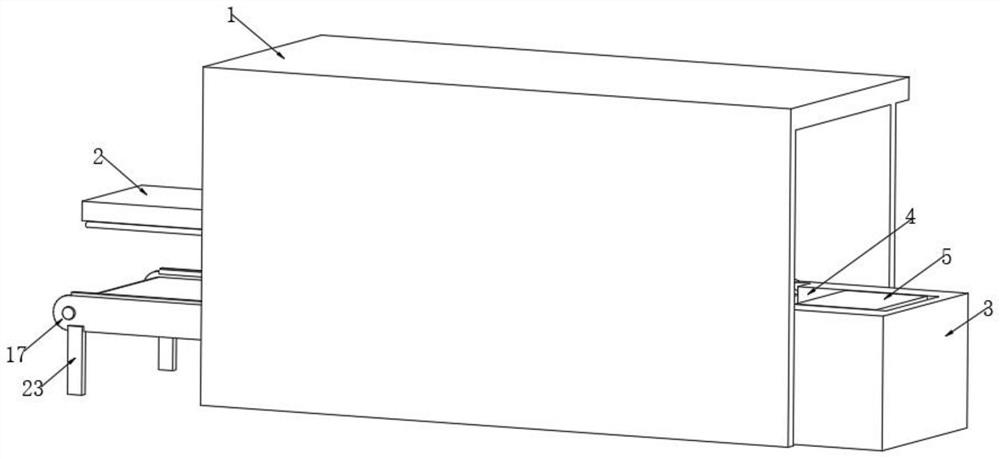

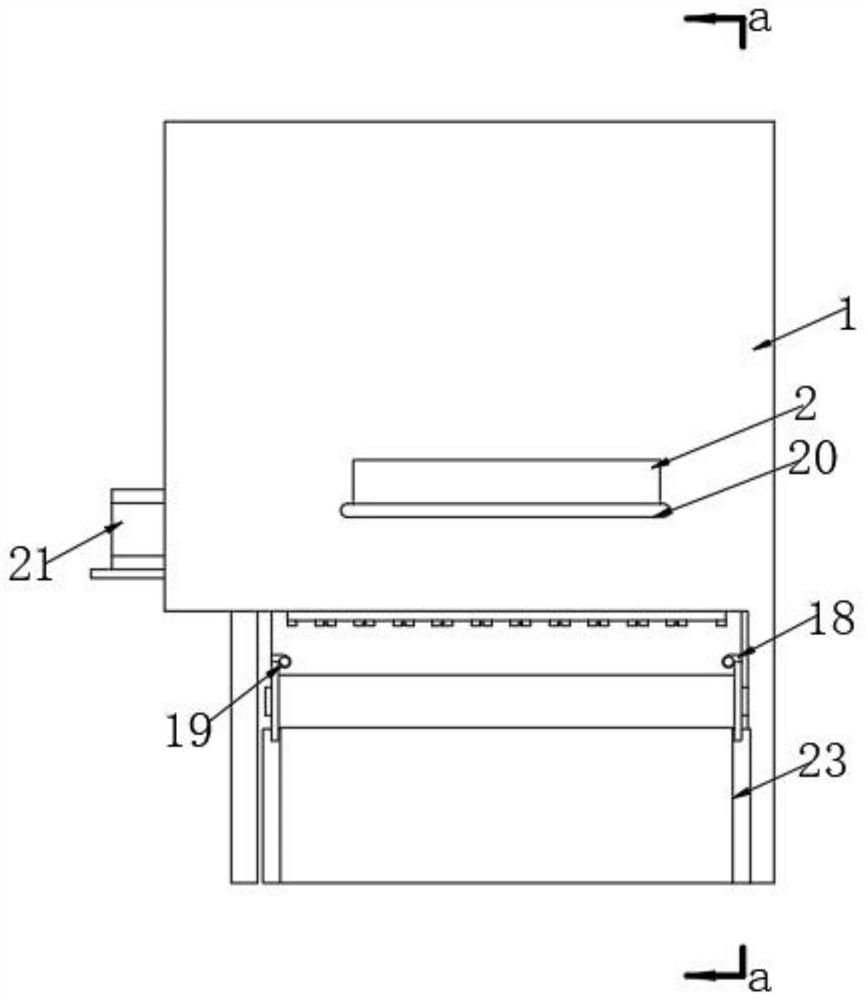

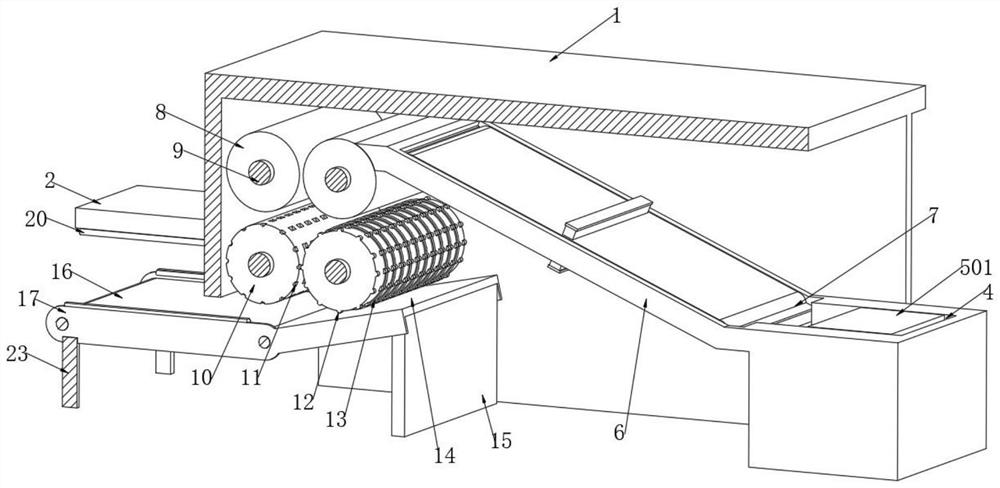

[0032] like Figures 1 to 9 As shown, the embodiment of the present invention provides a lace surface rapid pressing and forming machine, which includes a dust cover 1, a connecting plate 2 is integrally connected to one side surface of the dust cover 1, and the other side of the dust cover 1 is connected There is a fixed seat 3 in between, and a movable groove 4 is opened in the fixed seat 3, and a feeding assembly 5 is arranged in the movable groove 4. The feeding assembly 5 includes a fixed shaft 507, and the two ends of the fixed shaft 507 are rotatably connected On the inner wall surface of the fixed seat 3, the feeding assembly 5 is connected to the movable groove 4 through a fixed shaft 507, one end of the fixed seat 3 is integrally connected with a connecting frame 6, and a transmission assembly 7 is rotatably connected between the connecting frames 6 , the other end of the connecting frame 6 is provided with a rolling wheel 8, a pressing wheel 10 is arranged below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com