Fixation and strip tidying machine for tea processing

A technology of clearing machine and tea leaves, which is applied in tea treatment before extraction, etc. It can solve the problems of reducing production efficiency, increasing equipment cost, unfavorable continuous production, etc., and achieves the effects of improving production efficiency, low production cost and reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

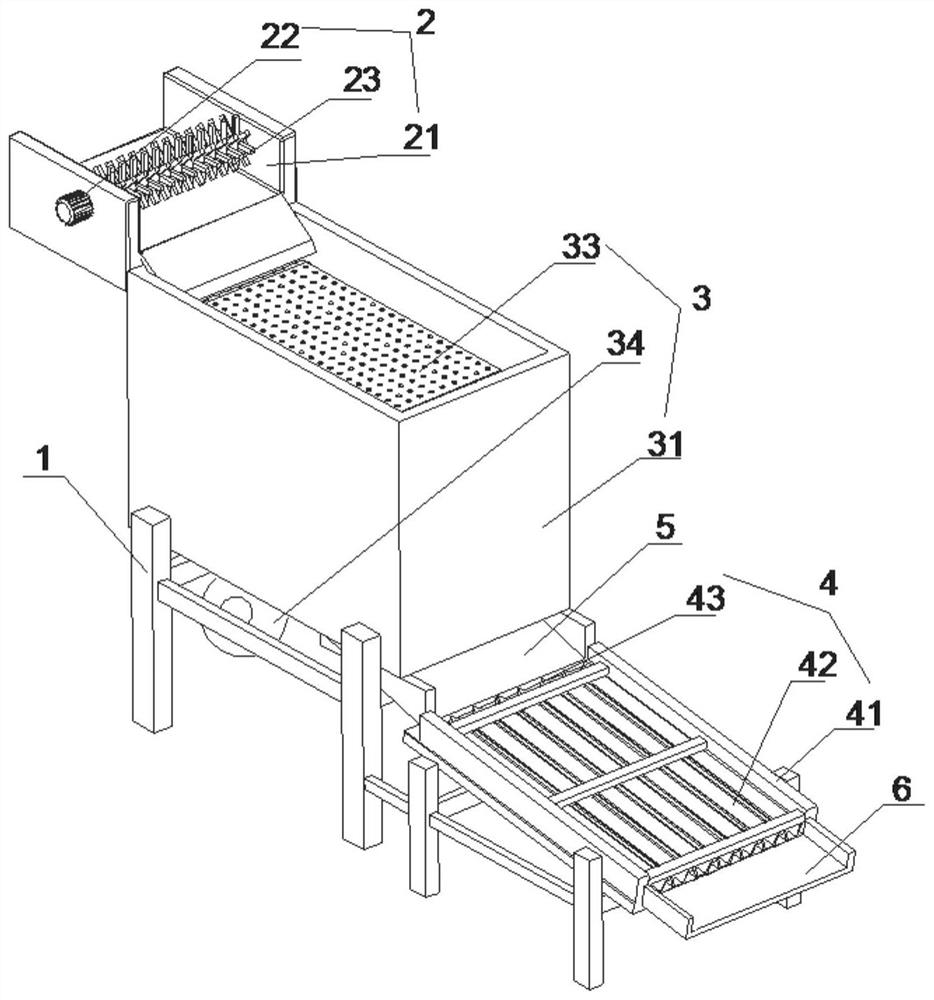

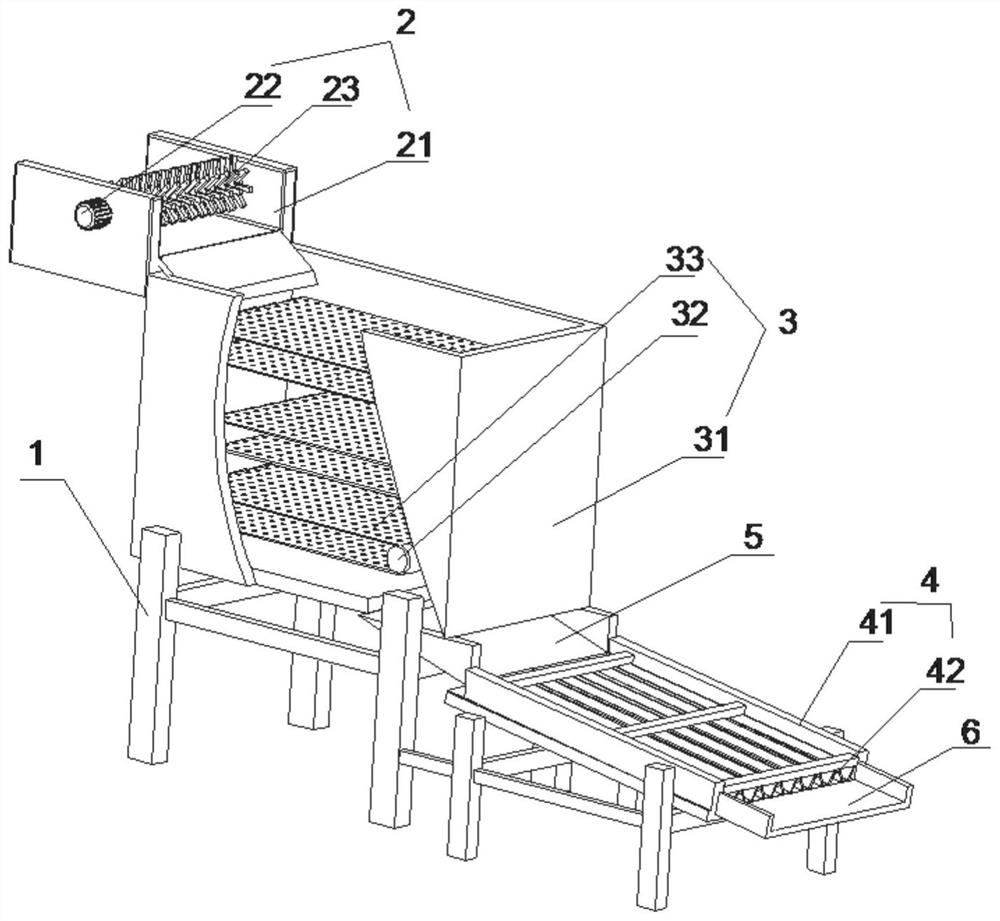

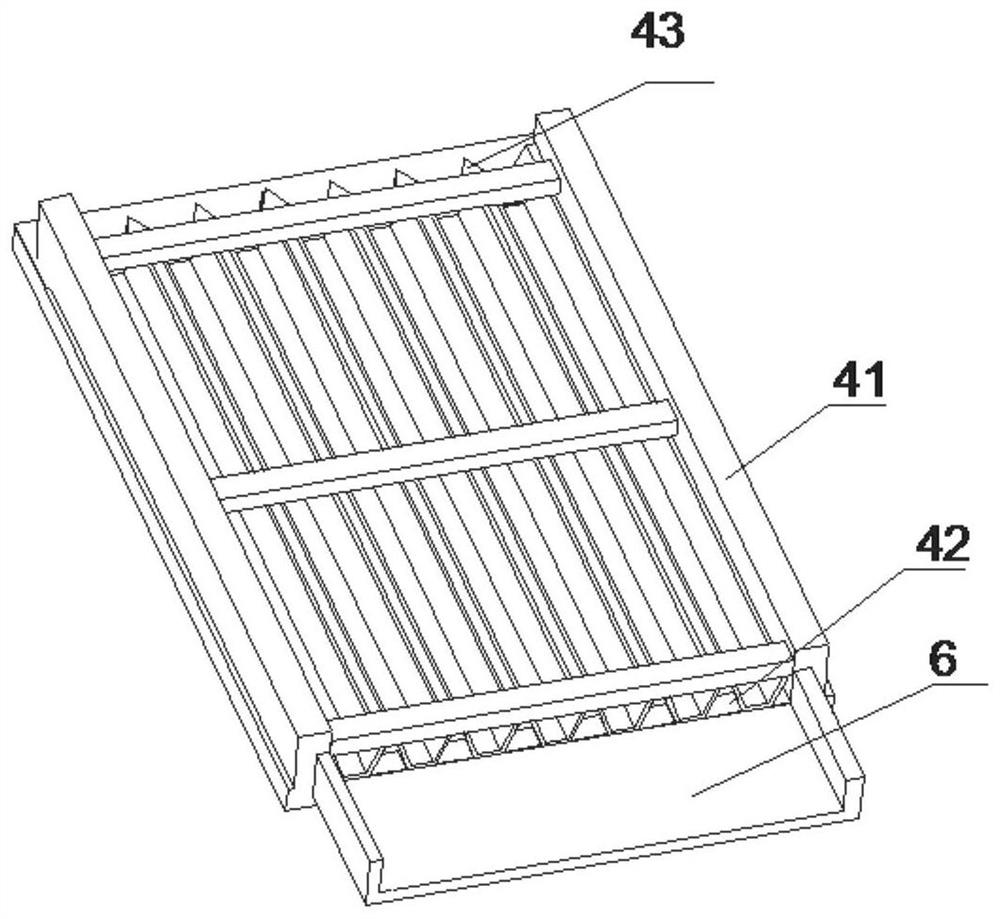

[0018] see Figure 1-3 , a tea processing machine for tea processing, comprising a frame 1 and a flattening part 2, a fixing part 3 and a stripping part 4 arranged on the frame 1, and the flattening part 2 is used for evenly arranging and paving the tea leaves. , to ensure that the tea leaves are heated and softened evenly when entering the greening part 3. The greening part 3 is used to soften the tea at high temperature and evaporate the moisture of the fresh leaves. The stripping part is used to shape the tea leaves. The conveying mechanism for conveying, the leveling part 2 is arranged at the upper end of the conveying mechanism on the side of the finishing part 3, the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com