Flame-retardant activated carbon for adsorbing ammonia gas and preparation method of flame-retardant activated carbon

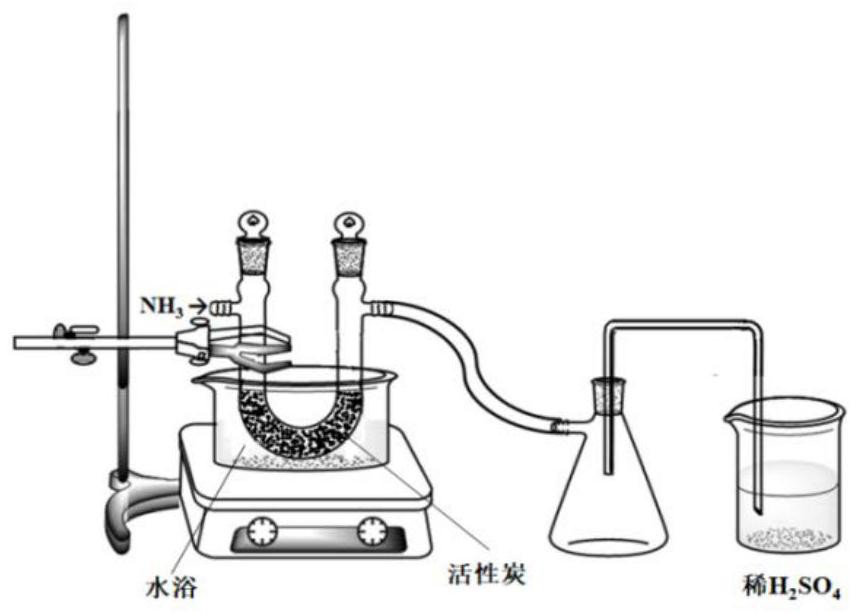

An activated carbon and flame retardant technology, applied in the field of flame retardant activated carbon and its preparation, can solve problems such as fire risk, and achieve the effects of avoiding fire danger, avoiding fire accidents, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

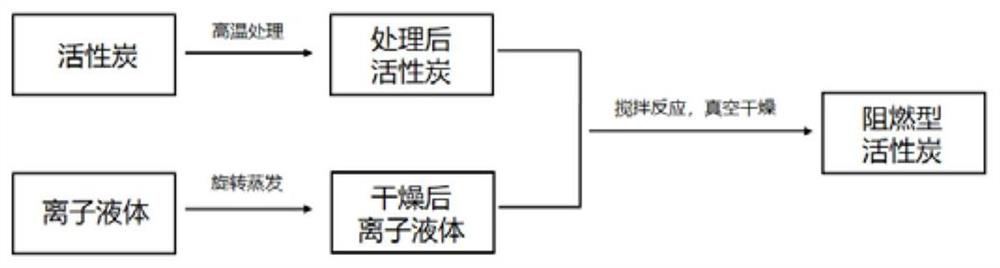

[0020] The activated carbon was calcined in a tube furnace at 400 °C for 12 h under nitrogen atmosphere. Take 1g[Bim]NO 3 Dissolve in 35mL of ethanol, slowly add 9g of calcined activated carbon, and stir at room temperature for 24h. Rotary steam at 80°C for 2h, rotation speed 40rpm, pressure 10kpa. After removing a large amount of ethanol, vacuum drying at 80°C for 24 hours, the vacuum degree is -90kpa, and the flame-retardant activated carbon 1 with a loading of 10wt% is obtained.

Embodiment 2

[0022] The activated carbon was calcined in a tube furnace at 400 °C for 12 h under nitrogen atmosphere. Take 1g[Eim]NO 3 Dissolve in 35mL of ethanol, slowly add 9g of calcined activated carbon, and stir at room temperature for 24h. Rotary steam at 80°C for 2h, rotation speed 40rpm, pressure 10kpa. After removing a large amount of ethanol, vacuum drying at 80°C for 24 hours, and the vacuum degree is -90kpa, to obtain flame-retardant activated carbon 2 with a loading of 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com