High-capacity 18650 lithium battery and preparation process thereof

A preparation process, lithium battery technology, applied in the direction of battery electrodes, secondary batteries, sustainable manufacturing/processing, etc., can solve the problems of insufficient environmental protection performance, reduced electrolyte stability, and large internal resistance of the electrolyte, etc., to achieve reduction Risk of spontaneous combustion, good development prospects, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

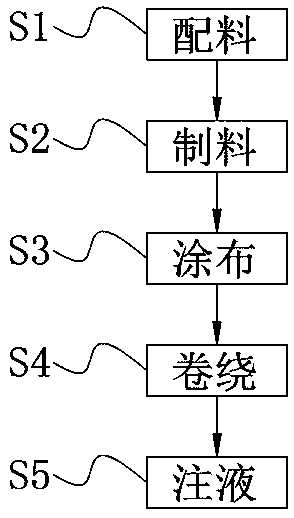

Method used

Image

Examples

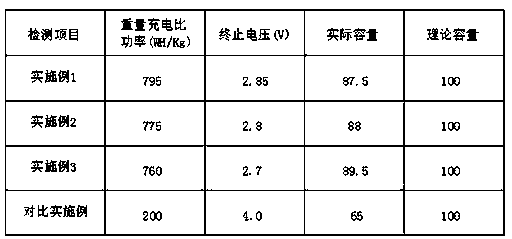

Embodiment 1

[0031] A high-capacity 18650 lithium battery, including positive electrode material, negative electrode material, electrolyte, casing and separator, the positive electrode material is divided into: positive electrode active material 90%, conductive agent 15%, binder 10%, balance as a solvent;

[0032] The negative electrode material is divided into: negative electrode active material 92%, binder 2%, thickener 2%, and the balance is solvent;

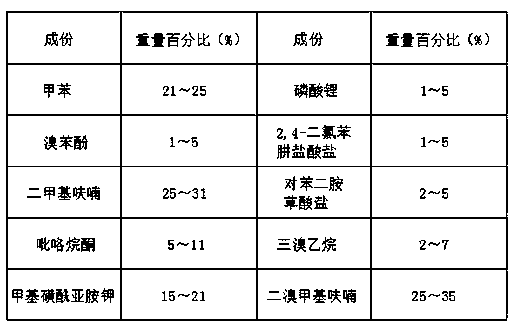

[0033] The electrolyte is divided into: 21% toluene, 1% bromophenol, 25% dimethylfuran, 5% pyrrolidone, 15% potassium methylsulfonimide, 1% lithium phosphate, 2,4-dichlorobenzene Hydrazine hydrochloride 1%, p-phenylenediamine oxalate 2%, tribromoethane 2%, dibromomethylfuran 25%.

[0034] Further, the positive electrode active material contained in the positive electrode material is one of nickel cobalt lithium manganese oxide and lithium manganese oxide, the conductive agent is graphene, and the binder is polyvinylidene fluoride.

[00...

Embodiment 2

[0050] A high-capacity 18650 lithium battery, including positive electrode material, negative electrode material, electrolyte, casing and separator, the positive electrode material is divided into: positive electrode active material 88%, conductive agent 12%, binder 9%, balance as a solvent;

[0051] The negative electrode material is divided into: negative electrode active material 93.5%, binder 2.5%, thickener 3%, and the balance is solvent;

[0052] The electrolyte is divided into: 25% toluene, 5% bromophenol, 31% dimethylfuran, 11% pyrrolidone, 21% potassium methylsulfonimide, 5% lithium phosphate, 2,4-dichlorobenzene Hydrazine hydrochloride 5%, p-phenylenediamine oxalate 5%, tribromoethane 7%, dibromomethyl furan 35%.

[0053] Further, the positive electrode active material contained in the positive electrode material is one of nickel cobalt lithium manganese oxide and lithium manganese oxide, the conductive agent is graphene, and the binder is polyvinylidene fluoride. ...

Embodiment 3

[0069] A high-capacity 18650 lithium battery, including positive electrode material, negative electrode material, electrolyte, casing and separator, the positive electrode material is divided into: positive electrode active material 86%, conductive agent 9%, binder 8%, balance as a solvent;

[0070] The negative electrode material is divided into: negative electrode active material 95%, binder 3%, thickener 4%, and the balance is solvent;

[0071] The electrolyte is divided into: toluene 23%, bromophenol 3%, dimethylfuran 27%, pyrrolidone 8%, methylsulfonimide potassium 18%, lithium phosphate 3.5%, 2,4-dichlorobenzene Hydrazine hydrochloride 3%, p-phenylenediamine oxalate 4%, tribromoethane 4.5%, dibromomethyl furan 30%.

[0072] Further, the positive electrode active material contained in the positive electrode material is one of nickel cobalt lithium manganese oxide and lithium manganese oxide, the conductive agent is graphene, and the binder is polyvinylidene fluoride.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com