Acoustic shock wave mixed soot blower for combustion flue

A technology of soot blowing device and furnace tunnel, which is applied to combustion methods, lighting and heating equipment, and removal of solid residues, etc., can solve the problems of many furnace tunnels, complex furnace tunnel shapes, and small expected pressure values, so as to ensure work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

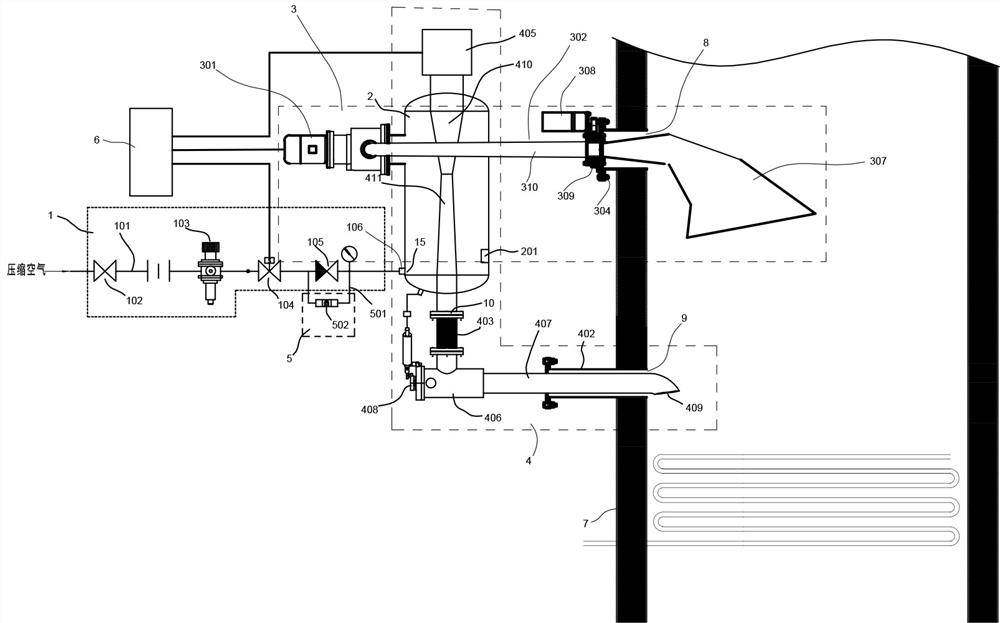

[0024] like figure 1The exemplary structure shown includes an air intake assembly 1, an energy storage tank 2, a scanning acoustic wave assembly 3, a scanning shock wave assembly 4, an intelligent pressure compensation unit 5, a control cabinet 6, an air intake assembly 1 and an energy storage device. The tank 2 is connected to provide a regulated gas source to the energy storage tank 2; the intelligent pressure compensation unit 5 is installed on the air intake assembly 1 and cooperates with the air intake assembly 1, and the intelligent pressure compensation unit 5 is used for the air intake assembly 1. Intelligent supplementary pressure; energy storage tank 2 is respectively connected with scanning acoustic wave assembly 3 and scanning shock wave assembly 4, and energy storage tank 2 is used to provide working high-pressure gas source to scanning acoustic wave assembly 3 and scanning shock wave assembly 4; mixing The soot blowing device cooperates with the furnace tunnel 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com