Spaceflight thermal control system enhanced condensing device based on space dot-matrix foam metal

A foam metal, space lattice technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of enhancing heat transfer coefficient, increasing resistance, etc., to increase heat transfer area, reduce flow resistance, and prepare low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

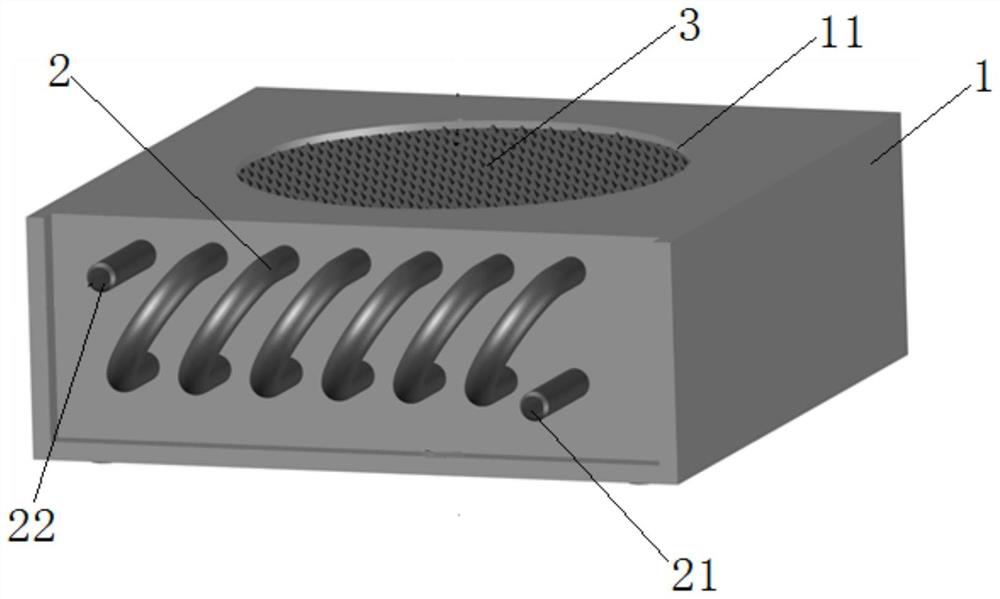

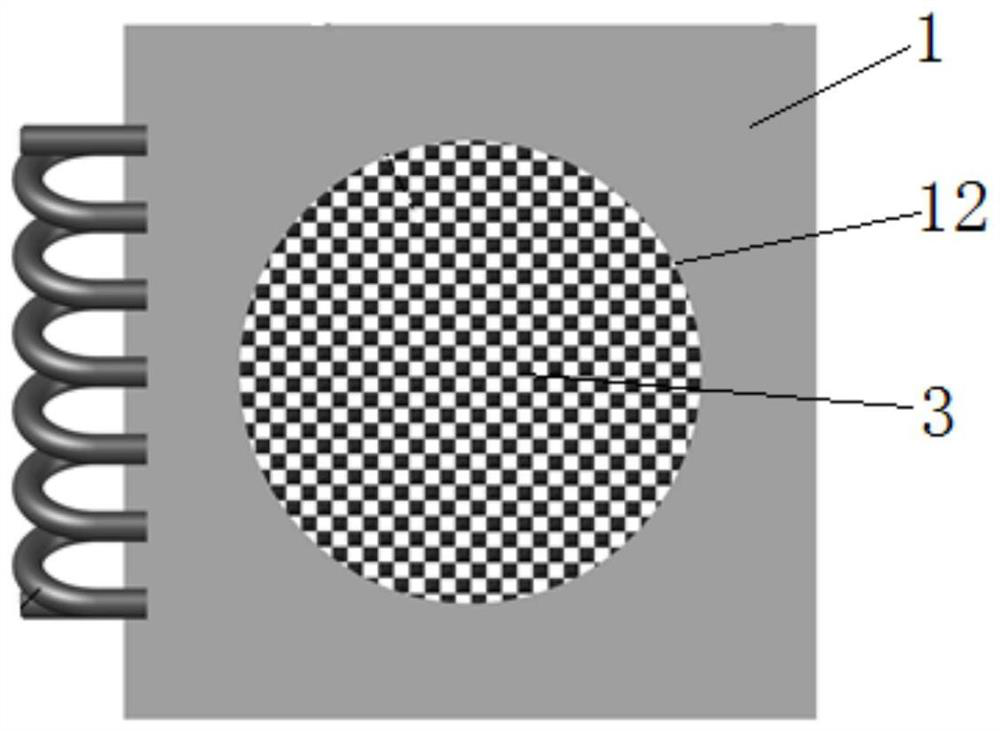

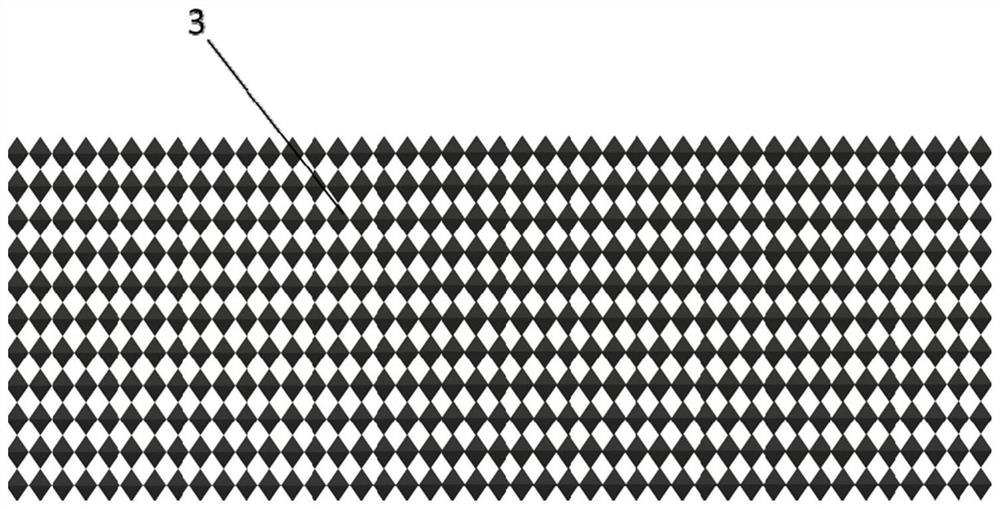

[0020] Figure 1-4 A specific embodiment of an aerospace thermal control system strengthening condensation device based on spatial lattice metal foam is shown, including a shell 1, a condensation heat exchange tube 2, a through-hole foam metal 3, and the condensation heat exchange tube 2 is screwed through. In the shell 1, the through-hole metal foam 3 is filled on the outer wall of the condensation heat exchange tube 2 inside the shell 1. The upper and lower ends of the shell 1 are respectively provided with a refrigerant inlet 11 and a refrigerant outlet 12. Inside the shell 1 Refrigerant is passed through, the lower end and the upper end of the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com