Power station boiler coal ash generation amount online prediction method and system based on LSTM

A forecasting method and technology for power station boilers, which are applied in forecasting, biological neural network models, data processing applications, etc., can solve problems such as difficult forecasting, large errors, and inconvenient practical application, and achieve reduction in equipment production loss and safe storage. The effect of exploiting, improving accuracy and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

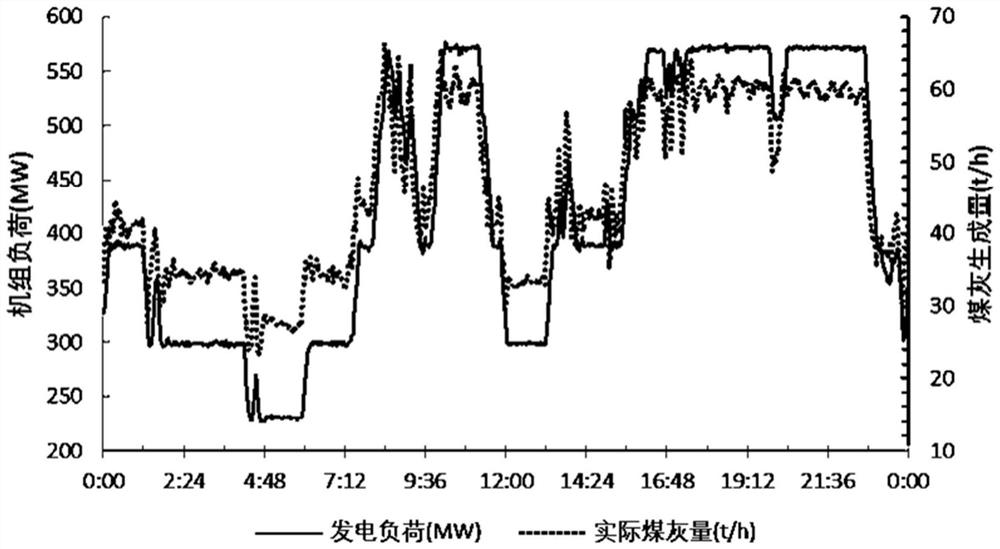

[0060] The invention proposes an LSTM-based on-line prediction method for the generation of coal ash in power station boilers. The LSTM neural network is suitable for processing time-series related data, and can reflect the main parameters affecting the generation of coal ash in the boiler, so that the coal ash in the boiler can be reflected. Production forecasts are more accurate. The prediction method of boiler coal ash generation based on LSTM deep learning can record the required data for a long time and can predict online, with a long prediction period and high precision, which can meet the dynamic prediction requirements of power generation enterprises for boiler coal ash generation.

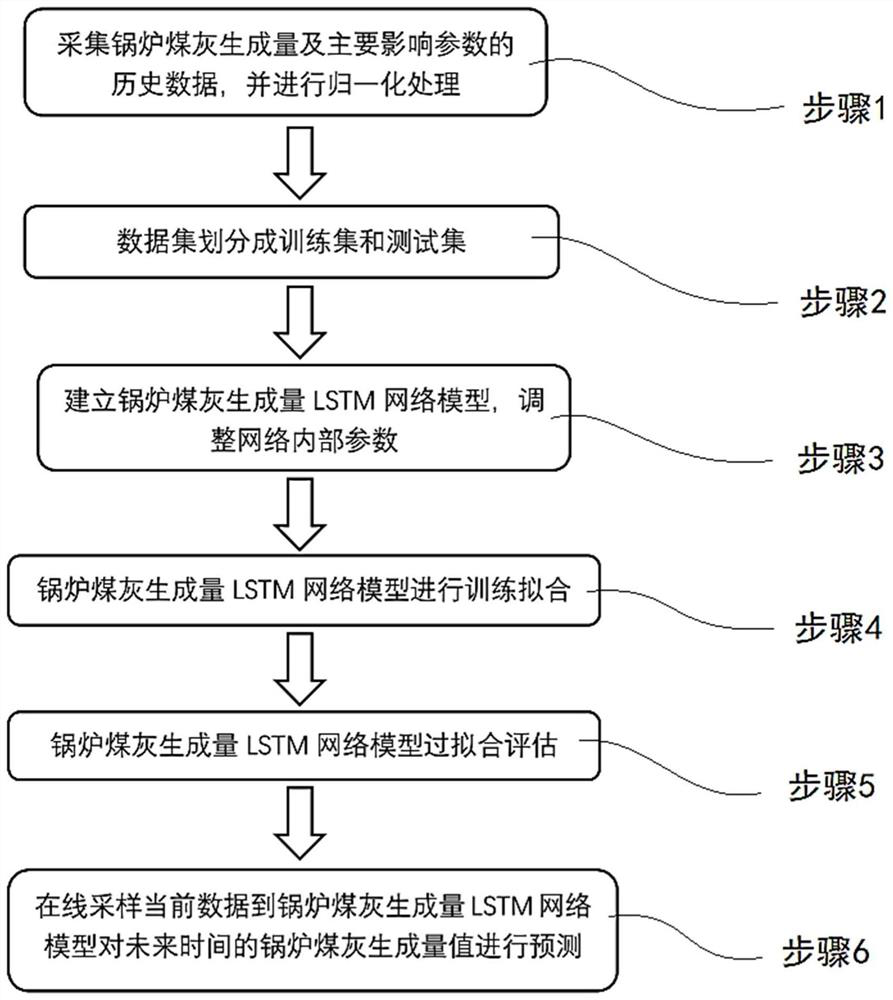

[0061] See figure 2 , an LSTM-based online prediction method for power plant boiler coal ash generation, comprising the following steps:

[0062] Step 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com