High-strength wear-resistant fire-resistant flame-retardant power cable and preparation method thereof

A power cable, high-strength technology, applied in the direction of power cables with shielding layer/conductive layer, cable/conductor manufacturing, insulated cables, etc., can solve the problems of low production efficiency, poor wear resistance and fire resistance of power cables, and achieve elasticity Good, increase wear resistance and fire resistance, improve the effect of compressive and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

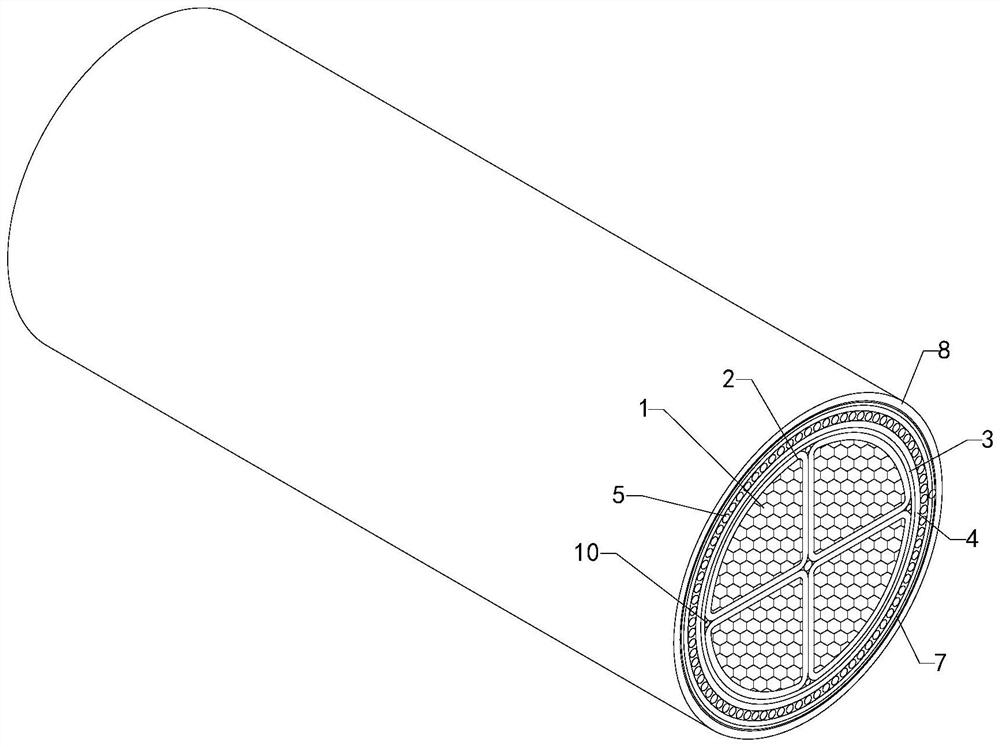

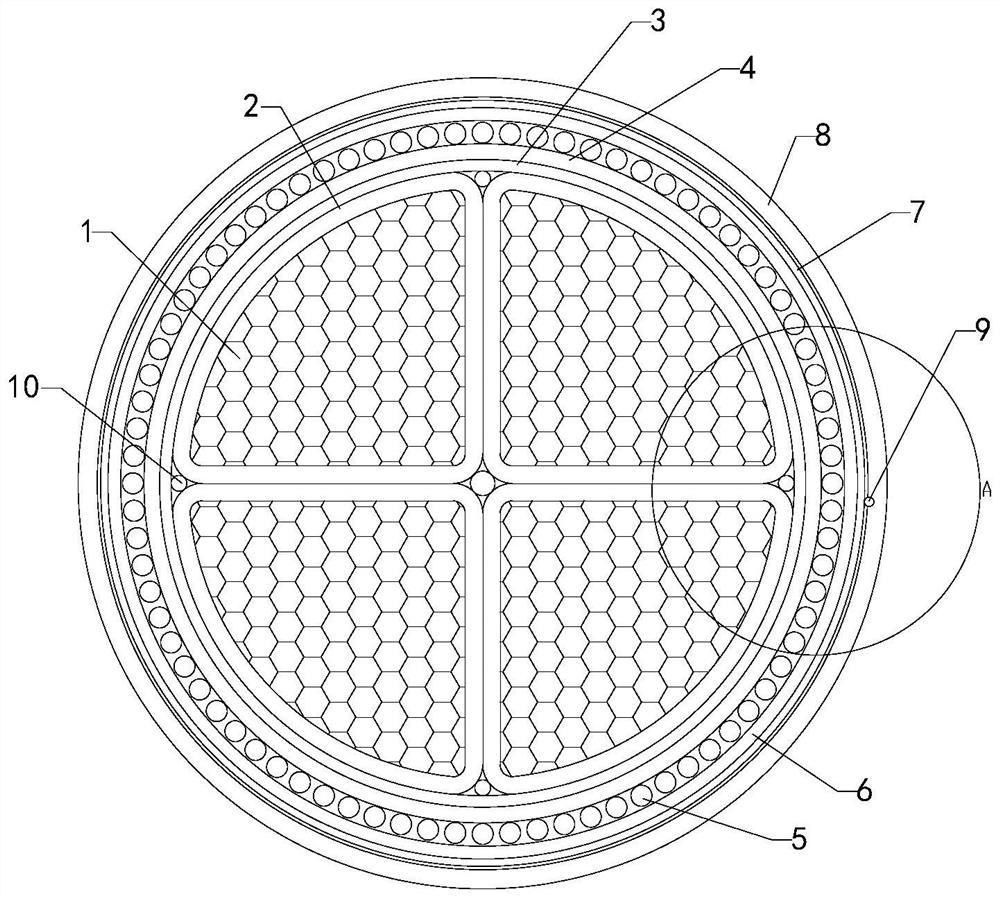

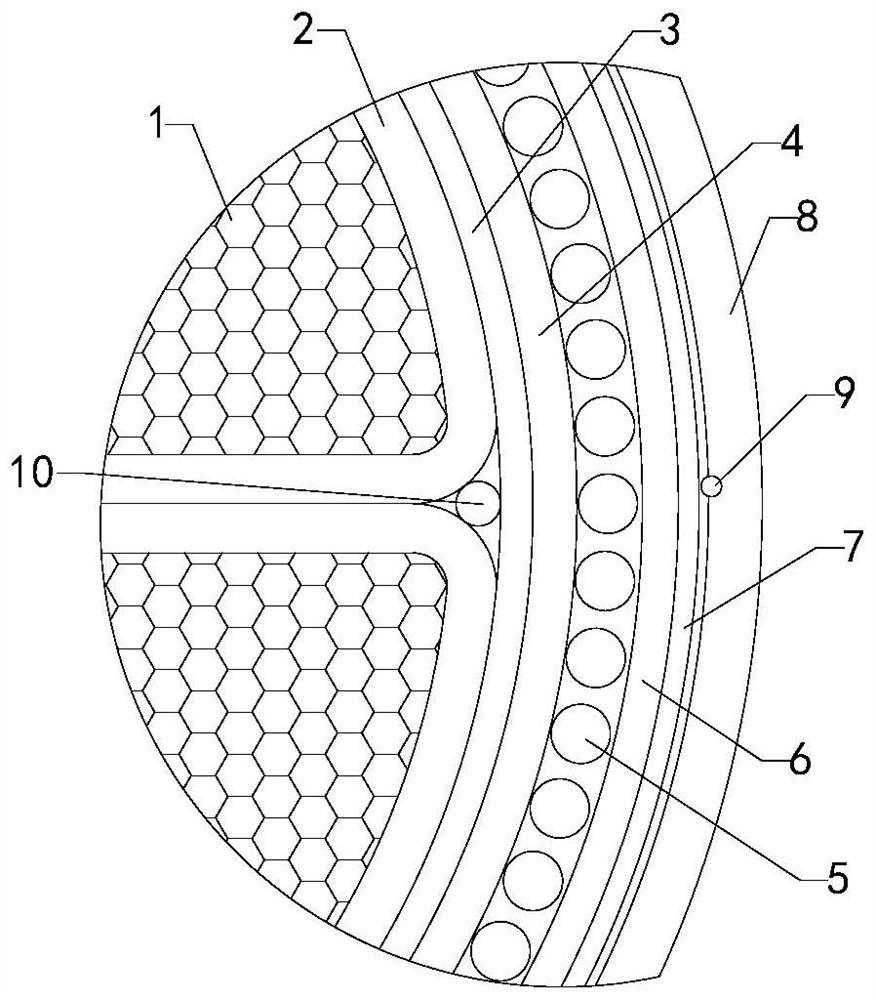

[0028] like Figure 1 to Figure 3 As shown in the figure, a high-strength wear-resistant, fire-resistant and flame-retardant power cable of the present invention and a preparation method thereof include a conductive unit, a tightening strap 3, an inner sheath 4, an armor layer 5, a polypropylene fiber layer 6, a corrugated aluminum sheath The sleeve 7, the outer sheath 8 and the filling rope 10, the tight tie 3 is wound on the outer walls of the four groups of conductive units, and the conductive units are in the shape of a quarter fan, and the tight tie 3 wraps the four groups of conductive units into a cylinder The inner sheath 4 is sheathed on the four groups of conductive units, the tight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com